A liquid-tight packaging bag

A technology for packaging bags and liquids, applied in the field of packaging bags, can solve the problems of troublesome sealing work, low product qualification rate, increased production cost, etc., and achieve the effect of reducing production cost, omitting sealing process, and improving product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

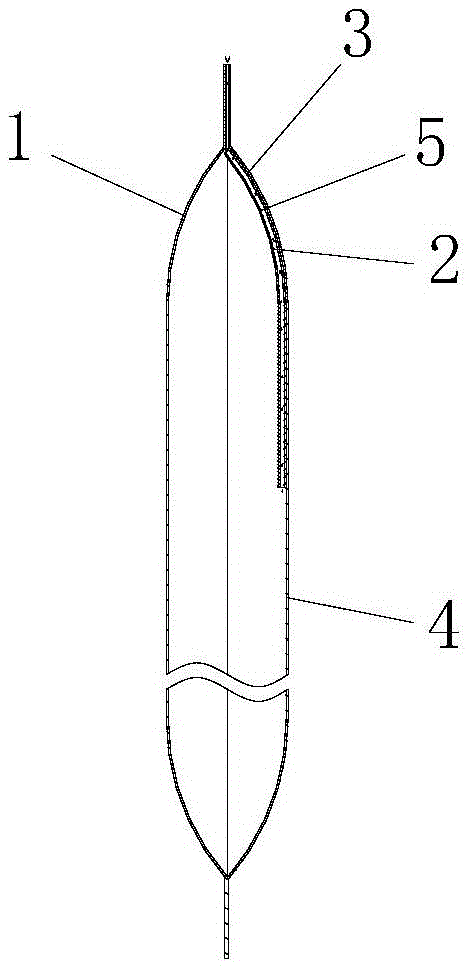

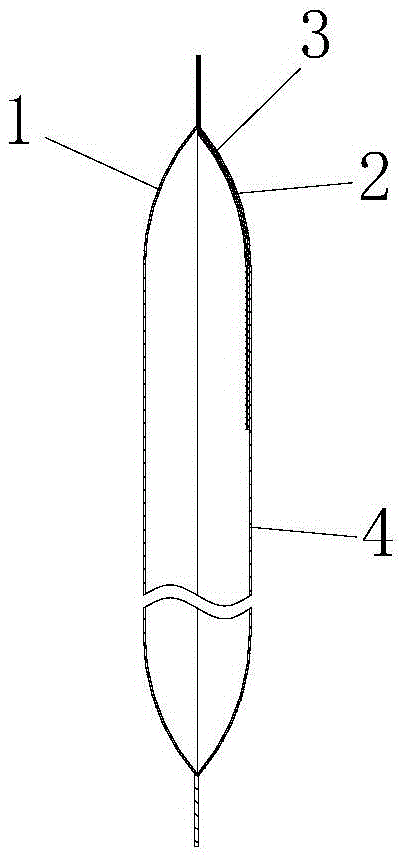

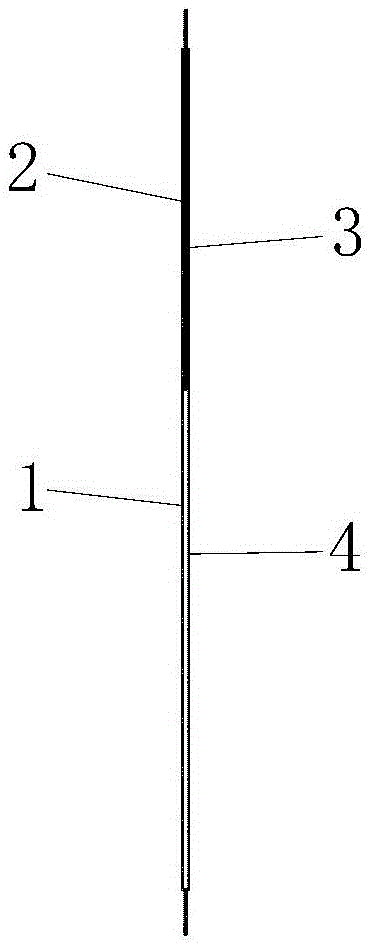

[0029] refer to Figure 1 to Figure 14 , a liquid-tight packaging bag comprising a first film 1, a second film 2, a third film 3 and a fourth film 4, the length of the first film 1 and the fourth film 4 being greater than that of the second film 2 and the length of the third film 3, the second film 2, the third film 3 are located between the first film 1 and the fourth film 4, the third film 3 is welded to the inner wall of the fourth film 4 , the local welding between the second film 2 and the third film 3 forms a liquid inlet channel 5 between the second film 2 and the third film 3, if the width of the second film 2 and the third film 3 is smaller than the first The width of the fourth film 4 of the film 1, the edge of the first film 1 is welded with the fourth film 4 to form a bag, if the first film 1, the second film 2, the third film 3 and the fourth film 4 If the widths are the same, the edge of the first film 1 is welded to the partial edges of the second film 2, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com