A kind of material location tracking method

A material and initial position technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems that the actual position of materials cannot be detected, and the transportation process cannot be tracked, etc., so as to facilitate calculation and processing and highlight the essence Features, effects of ensuring supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

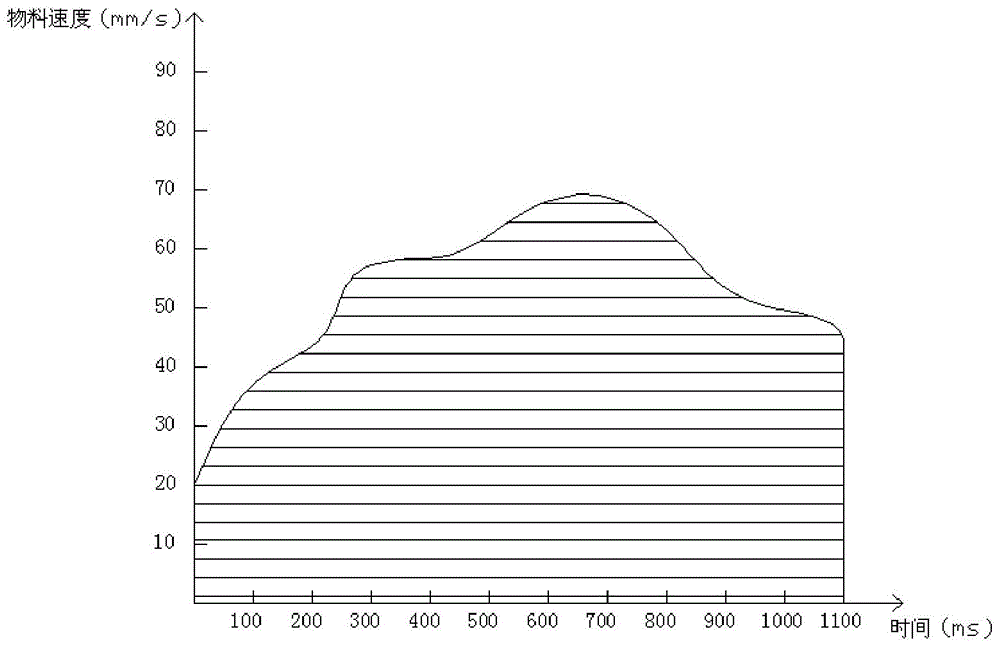

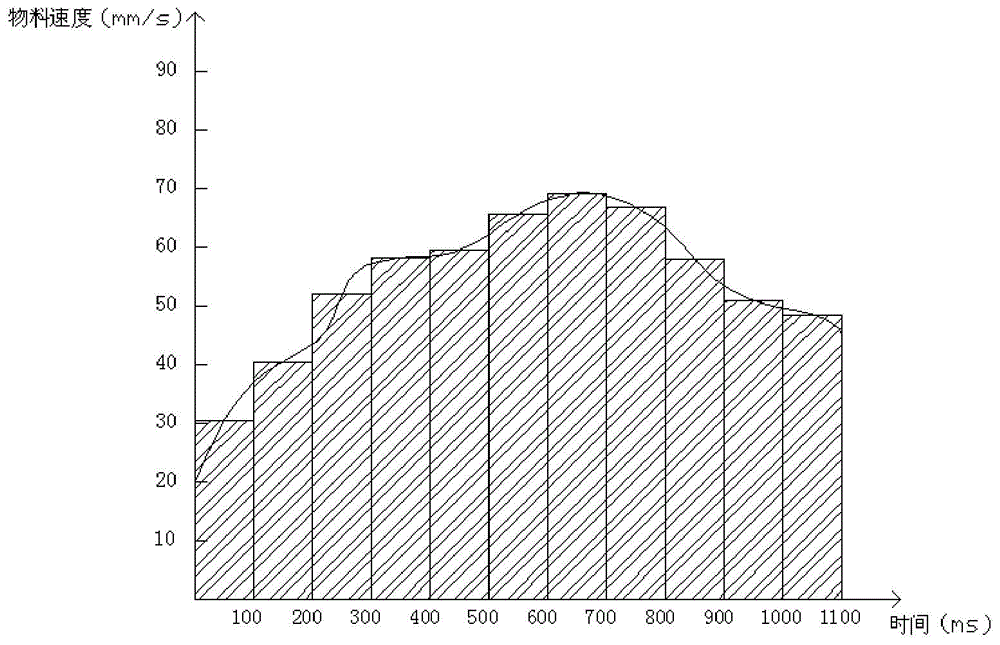

[0028] 1. Calculation of the linear position of the material

[0029] A roller conveying device used for conveying materials required for steel rolling, which uses a frequency converter to drive a motor to control the conveying speed of the materials. The frequency converter communicates with the PLC controller through communication, and transmits the actual running speed of the motor to the PLC controller in real time. The PLC controller controls the actual speed of the motor through the frequency converter. Calculate the real-time line speed of material conveying. Wherein, in this embodiment, the motor speed is N (rpm), the reduction ratio of the reduction box of the conveying equipment is p, and the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com