One-bath two-step dyeing method of nylon-cotton fabric

A fabric and nylon technology, applied in the field of fabric one-bath two-stage dyeing method, can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

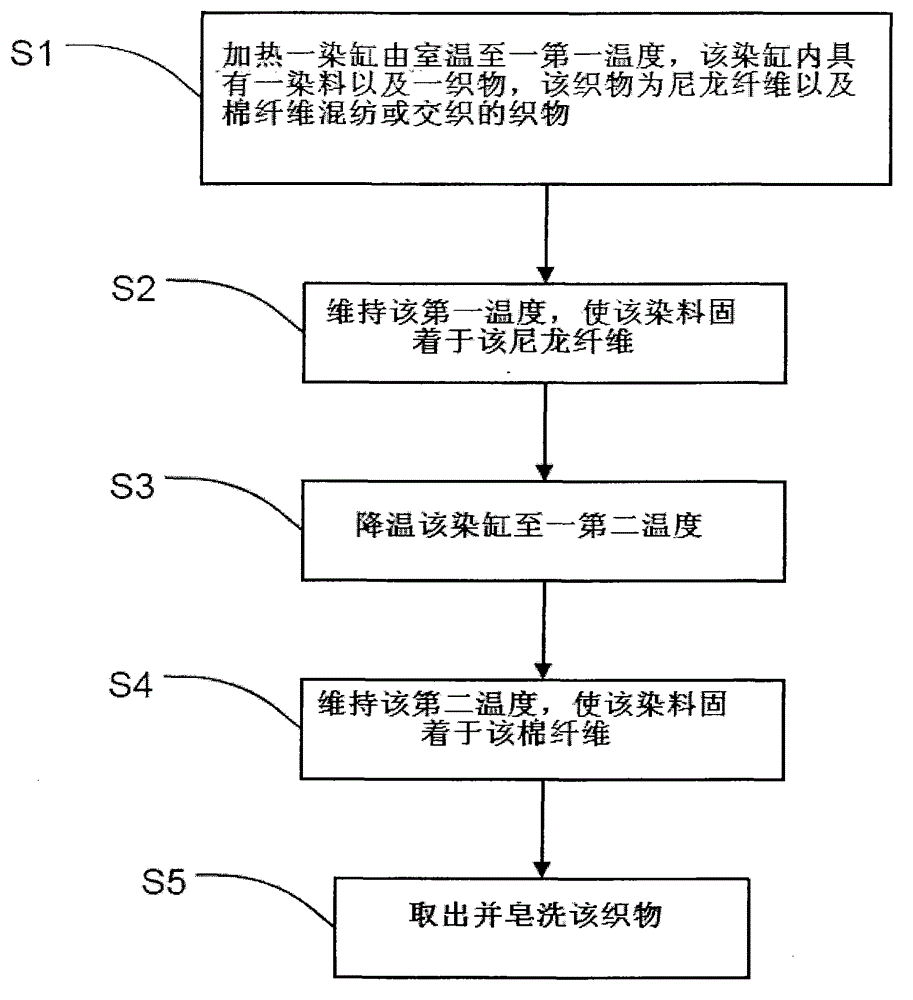

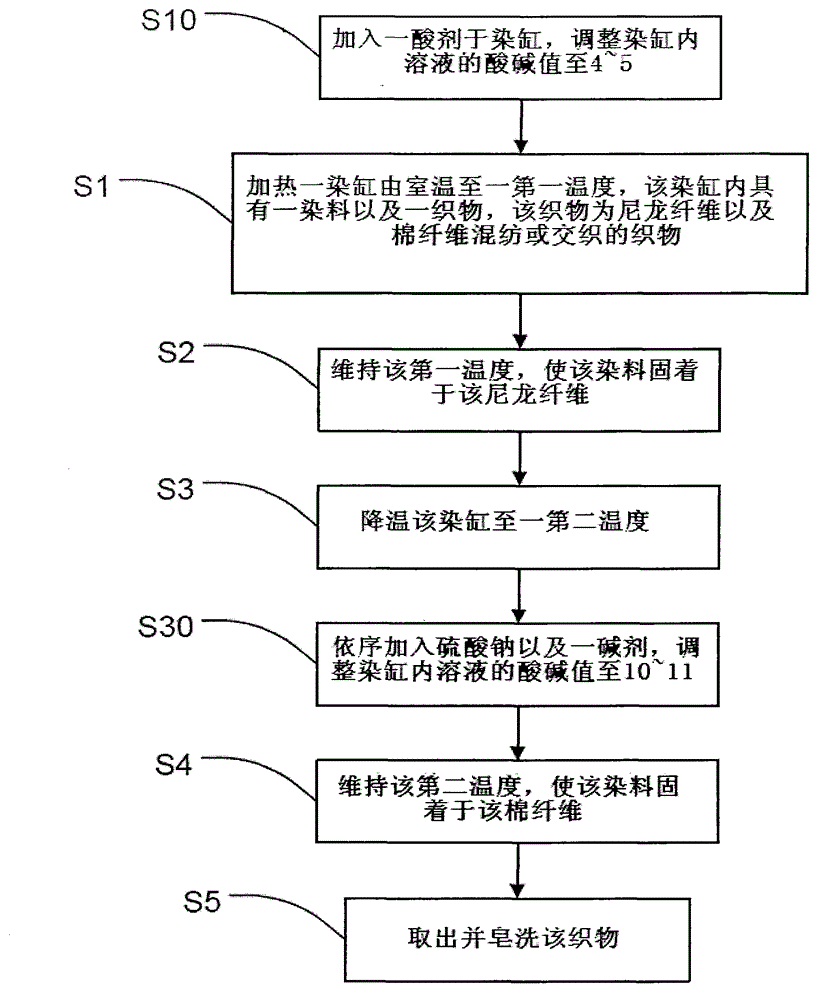

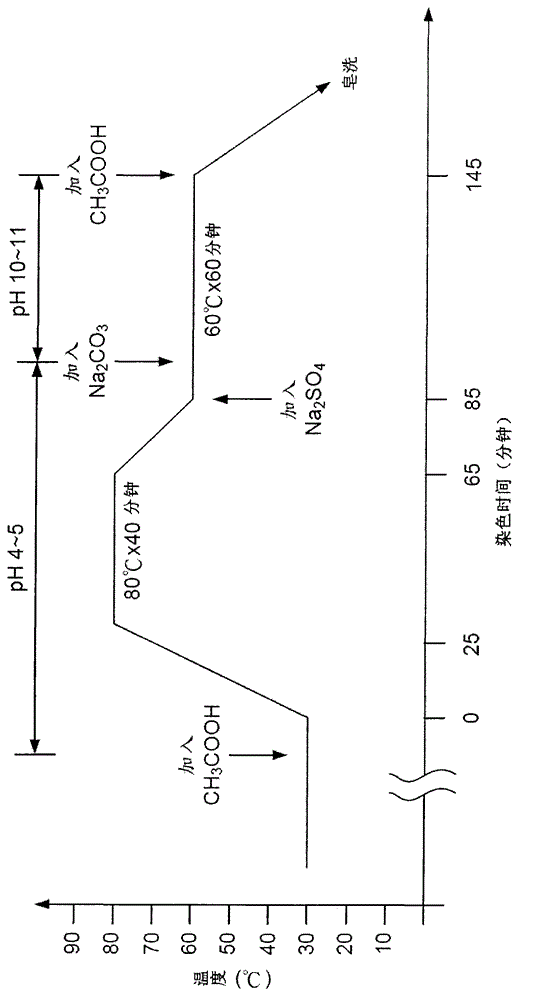

[0018] First, please refer to figure 1 , which is the basic and necessary operation steps of the present invention, which includes:

[0019] Step S1: heating a dye vat from room temperature to a first temperature, the dye vat has a dye and a fabric, and the fabric is a blended or interwoven fabric of nylon fibers and cotton fibers;

[0020] Step S2: maintaining the first temperature to fix the dye to the nylon fiber;

[0021] Step S3: cooling down the dye vat to a second temperature;

[0022] Step S4: maintaining the second temperature to fix the dye to the cotton fiber; and

[0023] Step S5: Taking out and soaping the fabric.

[0024] Wherein, the dye is an acid reactive dye.

[0025] Before operating the method of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com