Horn-shaped compression spring

A compression spring and trumpet-shaped technology, which is applied in the field of compression springs to achieve the effects of improving safety, reducing stress, and increasing the uniformity of load force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

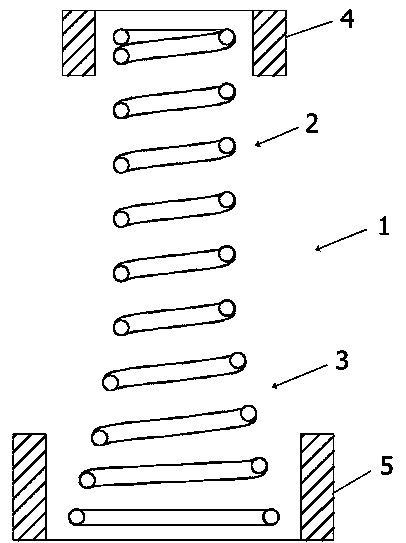

[0014] The invention provides a horn-shaped compression spring, which is mainly used in the environment where the installation space is narrow and long, especially the compression spring in the oil pump, the spring length is required to be longer, and the horn-shaped configuration enlarges the contact area between the compression spring and the counterpart. In order to increase the uniformity of the load and prevent the compression spring itself from being deformed and bent due to the load, the performance of the compression spring will be reduced.

[0015] like figure 1 As shown, the compression spring of the present invention includes a spring body, the spring body is formed by curling and stacking metal wires, the cross section of the metal wires is circular, the spring body is a horn-shaped structure, and its upper end is a cylindrical part , the lower end is a frustum-shaped part. Regarding the selection of spring raw materials, although the special-shaped steel wire ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com