Single-layer cyclone device for combustion chamber of heater

A combustion chamber and heater technology, which is applied to burners, lighting and heating equipment, etc., can solve the problems of affecting the combustion-supporting effect of cyclones, unfavorable combustion chamber efficiency, low cyclone cutting force, etc., and achieves extended service life and atomization effect. Good, reducing the effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

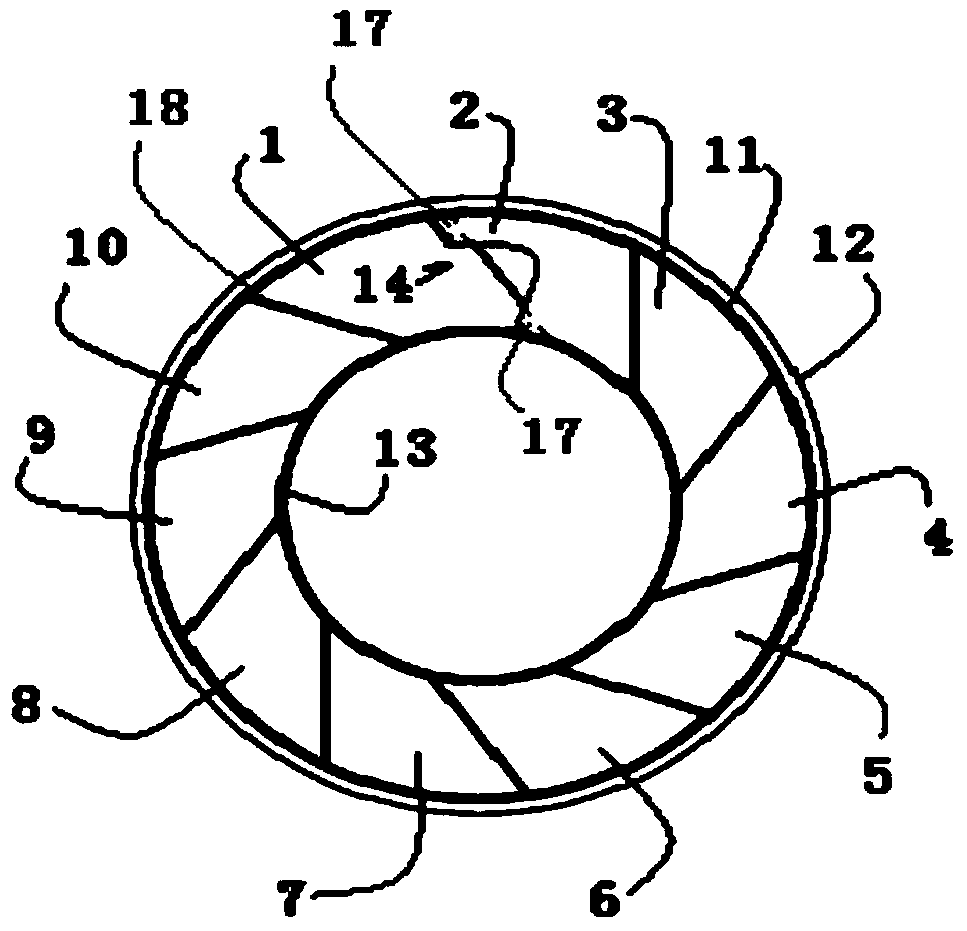

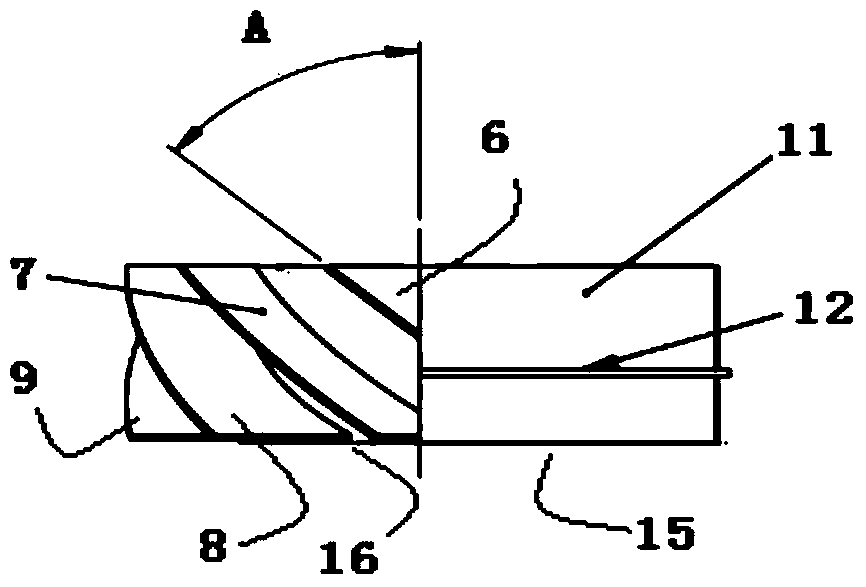

[0020] Below with the accompanying drawings ( Figure 1-Figure 3 ) to illustrate the present invention.

[0021] figure 1 It is a structural schematic diagram of a heater combustion chamber single-layer cyclone device implementing the present invention. figure 2 It is a schematic diagram of the structure of the outer cylinder and inner cyclone blades of the cyclone device. Such as figure 1 and figure 2 As shown, a single-layer cyclone device for a heater combustion chamber is characterized in that it includes a cylinder body 11 and several cyclone blades (for example, from the first cyclone blade 1 to the tenth cyclone blade 10), and the several cyclone blades are along the The inner wall of the cylinder 11 is distributed successively to form a cyclone ring (for example, comprising a first cyclone blade 1, a second cyclone blade 2, a third cyclone blade 3, a fourth cyclone blade 4, a fifth cyclone blade 5, and a sixth cyclone blade. Blade 6, the seventh whirlwind blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com