Electric energy storage air heater

A technology of hot air blower and induced draft fan, which is applied in the direction of heat storage equipment, electric heating system, space heating and ventilation, etc., and can solve the problems of unfavorable energy storage equipment intensification, modularization, limited pavement height, and complicated construction. Achieve the effect of good heat transfer, simple structure and large energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

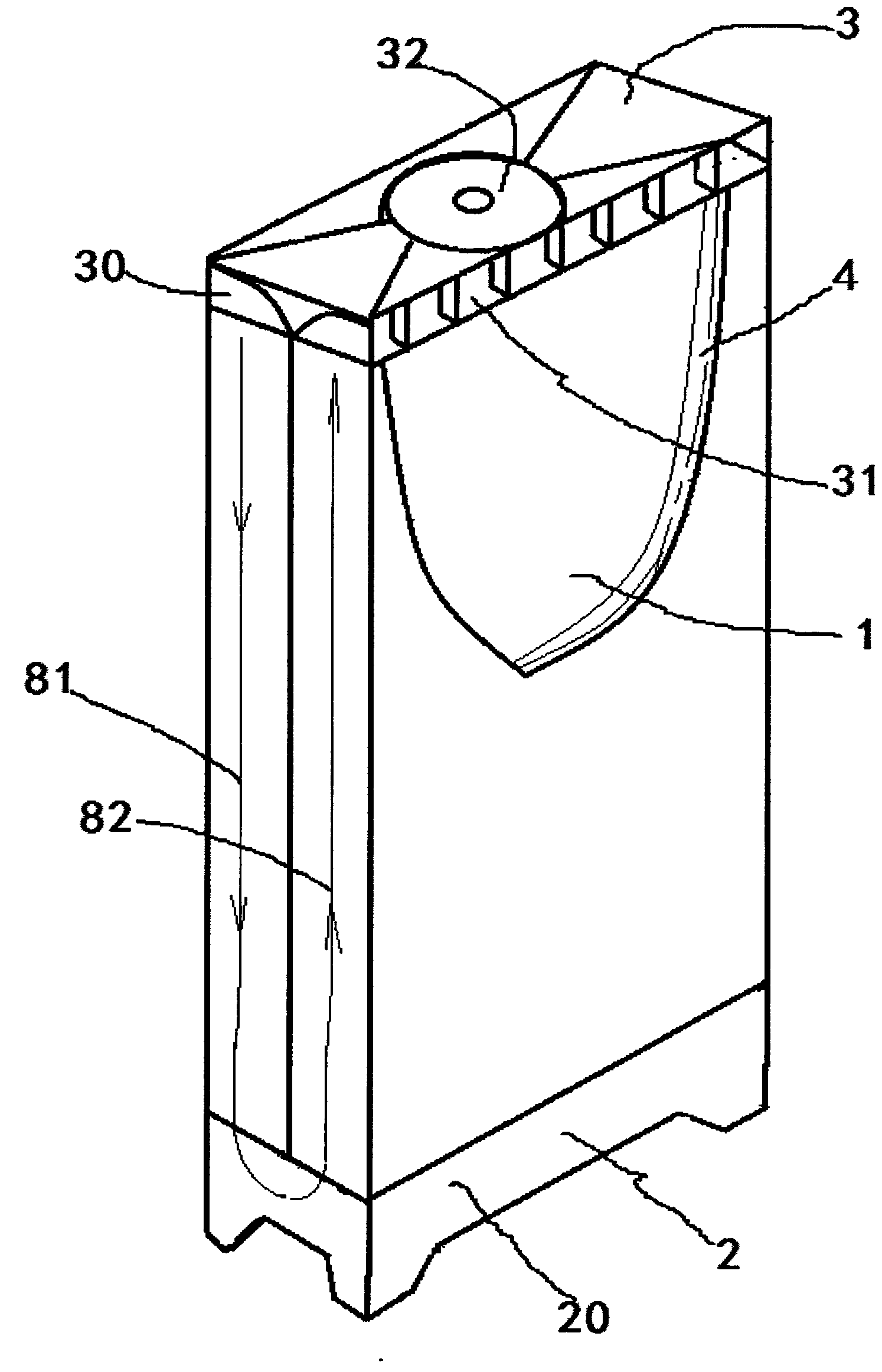

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, an electric energy storage hot air blower includes several energy storage units 1, a base 2, a top cover 3, a thermal insulation shell 4 and an electrical control system 5, and each energy storage unit 1 is provided with a phase change accumulator Energy material 6 and electric heating element 7.

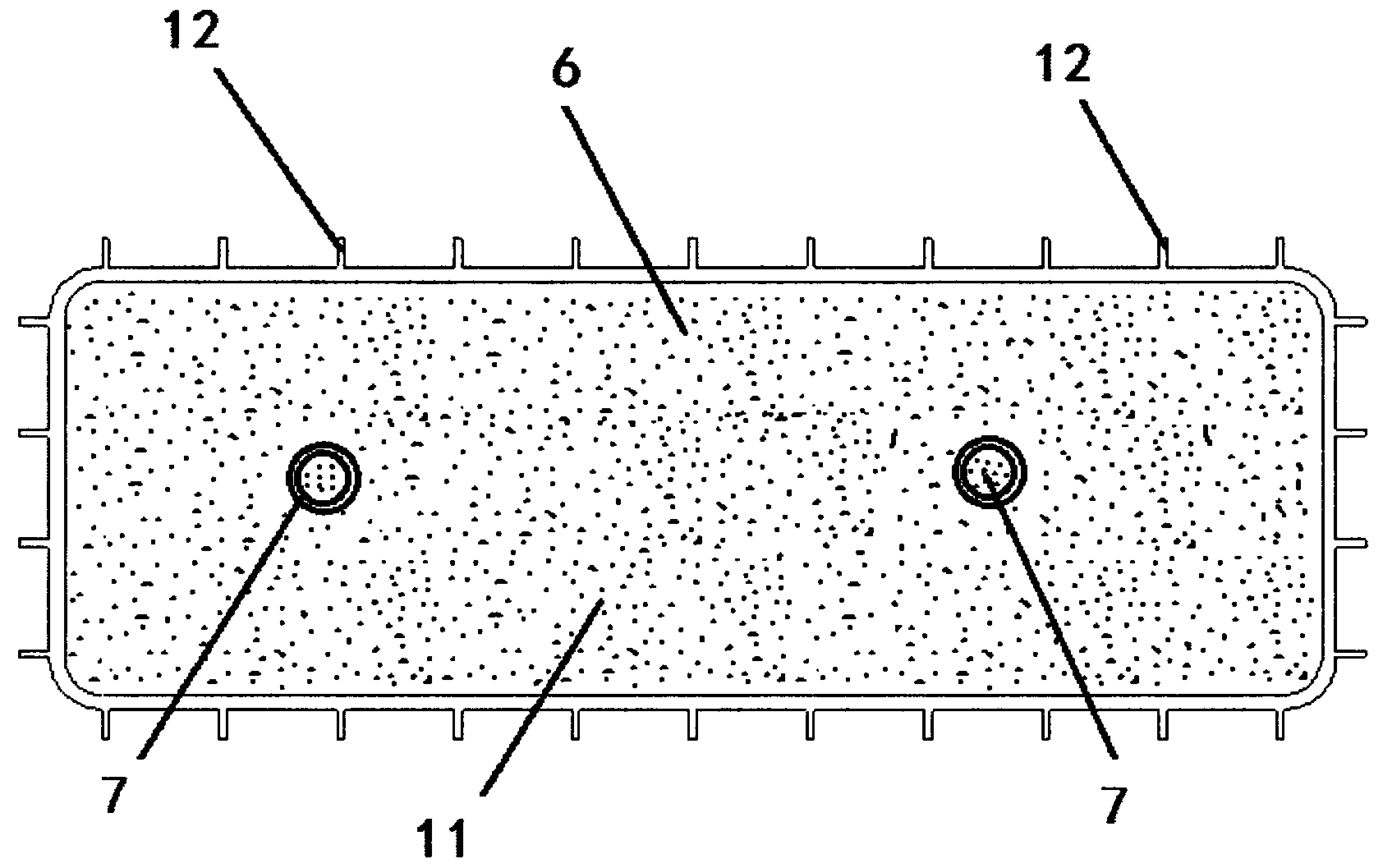

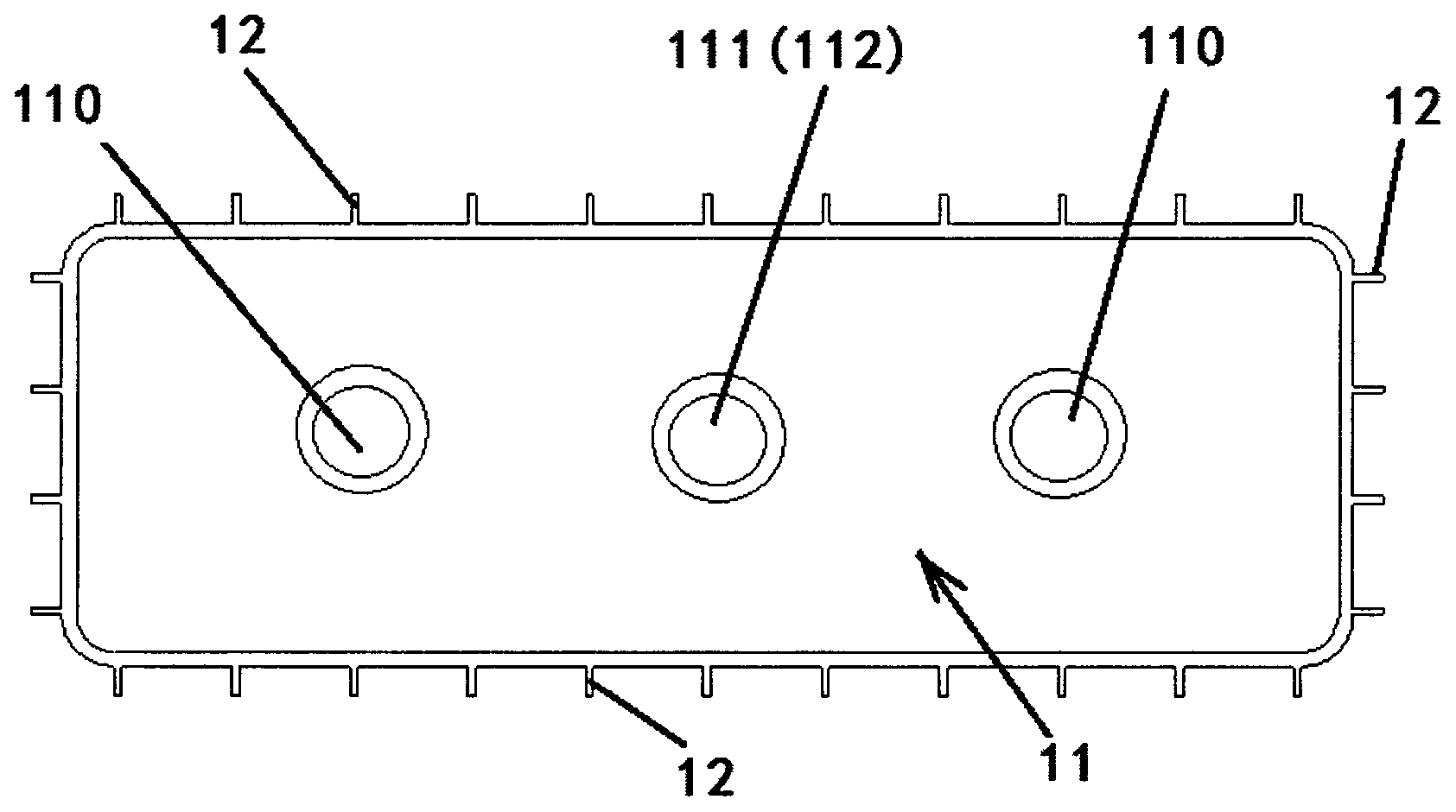

[0033] Such as figure 2 , image 3 , Figure 4 , Figure 9 As shown, each energy storage cell 1 includes an energy storage cavity 11, and a plurality of heat dissipation strips 12 are arranged on the outer surface of each energy storage cell 1. The energy storage cavity 11 and the heat dissipation strip 12 are integrally structured. An air channel 8 is formed between the energy storage cells 1 and between the energy storage cells 1 and the inner wall of the heat-insulating shell 4, the energy storage cavity 11 is in the shape of a closed conta...

Embodiment 2

[0038] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, an electric energy storage hot air blower includes several energy storage units 1, a base 2, a top cover 3, a thermal insulation shell 4 and an electrical control system 5, and each energy storage unit 1 is provided with a phase change accumulator Energy material 6 and electric heating element 7.

[0039] Such as figure 2 , image 3 , Figure 4 , Figure 9 As shown, each energy storage cell 1 includes an energy storage cavity 11, and a plurality of heat dissipation strips 12 are arranged on the outer surface of each energy storage cell 1. The energy storage cavity 11 and the heat dissipation strip 12 are integrally structured. An air channel 8 is formed between the energy storage cells 1 and between the energy storage cells 1 and the inner wall of the heat-insulating shell 4, the energy storage cavity 11 is in the shape of a closed c...

Embodiment 3

[0044] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 11 As shown, an electric energy storage hot air blower includes several energy storage units 1, a base 2, a top cover 3, a thermal insulation shell 4 and an electrical control system 5, and each energy storage unit 1 is provided with a phase change accumulator Energy material 6 and electric heating element 7.

[0045] Such as figure 2 , image 3 , Figure 4 , Figure 9 As shown, each energy storage cell 1 includes an energy storage cavity 11, and a plurality of heat dissipation strips 12 are arranged on the outer surface of each energy storage cell 1. The energy storage cavity 11 and the heat dissipation strip 12 are integrally structured. An air channel 8 is formed between the energy storage cells 1 and between the energy storage cells 1 and the inner wall of the heat-insulating shell 4, the energy storage cavity 11 is in the shape of a closed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com