Effective frost layer sensing device and defrosting control method thereof

A technology for sensing device and frost layer, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low social and economic benefits, difficult installation of control components, residual frost layer on fins, etc., and achieve manufacturing costs. Low, easy to mass production, not easy to misjudge the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the drawings and embodiments. It should be pointed out that the embodiments of the present invention do not limit the scope of the present invention.

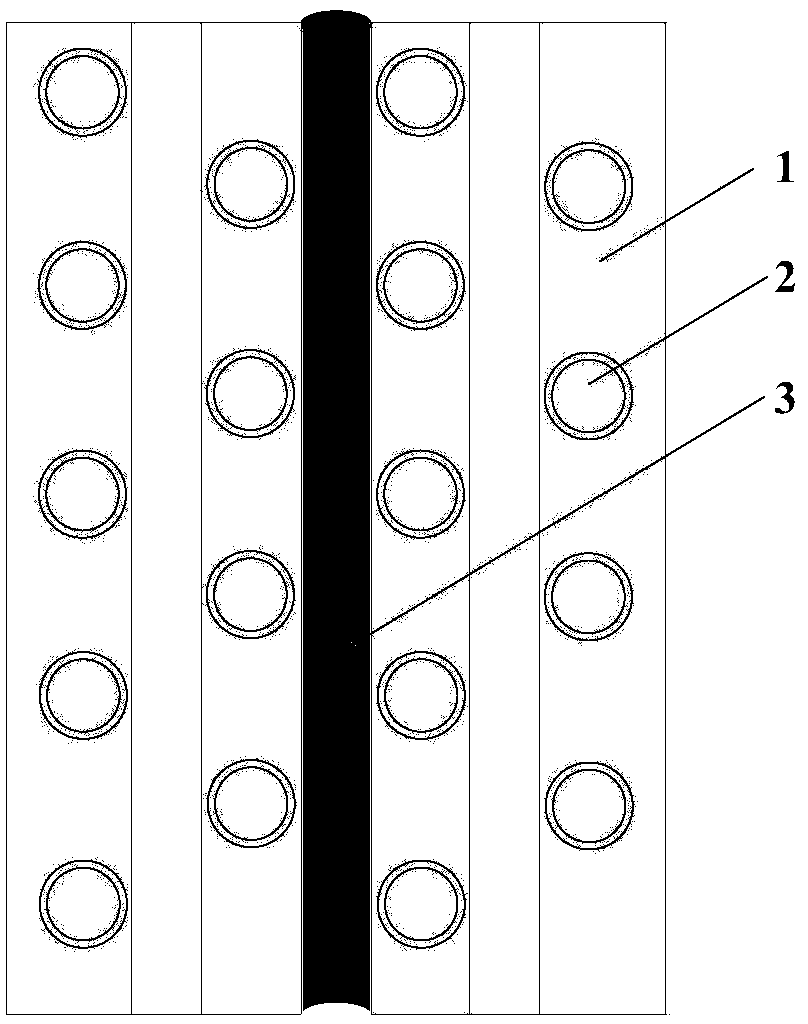

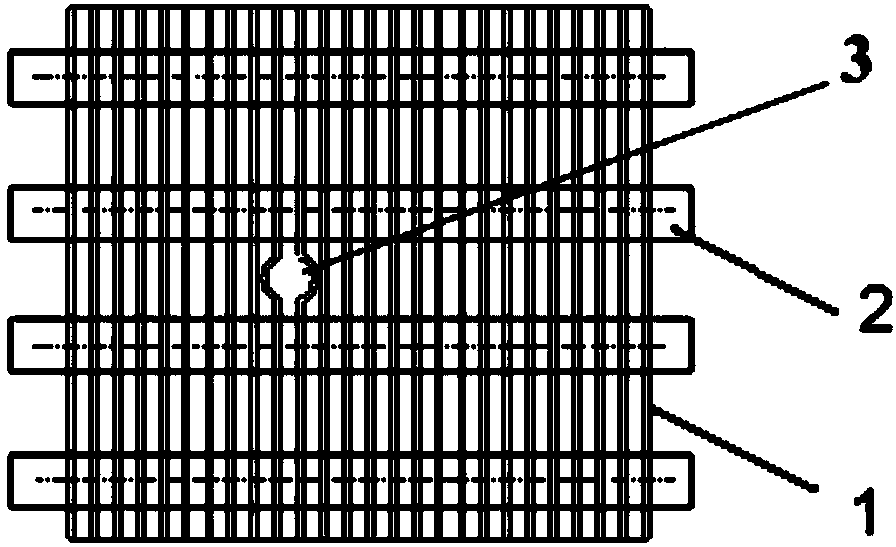

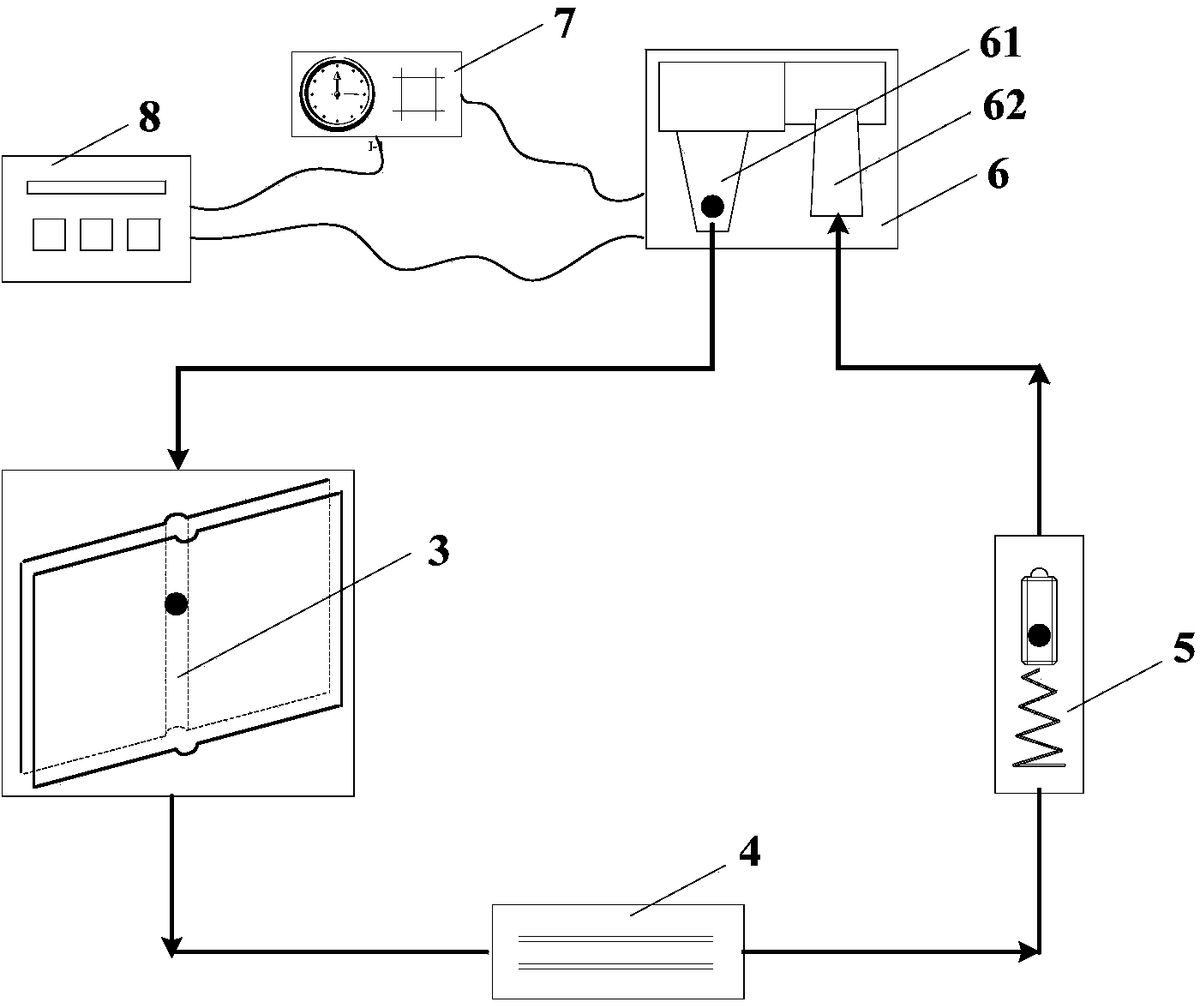

[0036] An effective frost detection device according to the present invention comprises an outdoor finned heat exchanger with an arc-shaped slideway and a small ball launching circulation device. Such as figure 1 and 2 As shown, the outdoor fin heat exchanger is provided with an arc-shaped slideway 3, and the arc-shaped slideway 3 is composed of two fins 1 with arc-shaped grooves. Such as image 3 As shown, the described ball launch cycle device is mainly composed of arc slideway 3, bottom sliding track 4, automatic ejector 5, launcher 6, launch timer 7, defrosting controller 8 and small balls.

[0037] combine Figure 4 , the specific steps of the defrosting control method using the above-mentioned frost layer effective sensing device describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com