Indirect air-cooled tower

An air-cooling tower, indirect technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of high technical difficulty in radiator repair, easy cracking of radiator finned tubes, and intercooling System and unit outage and other problems, to save economic costs, simple structure, solve the effect of winter antifreeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

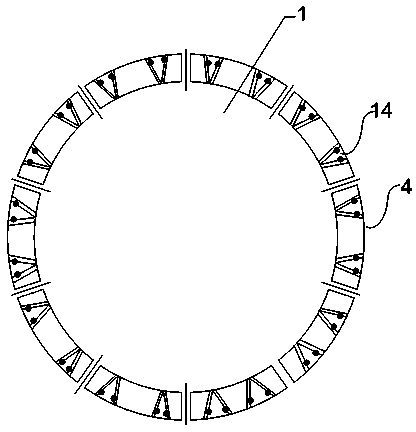

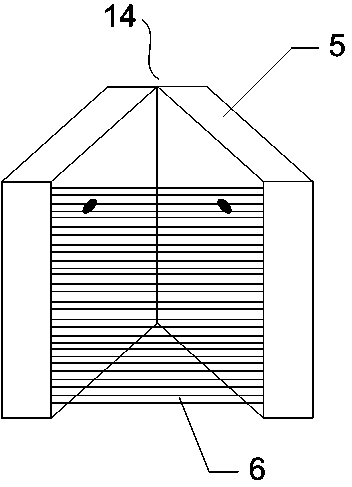

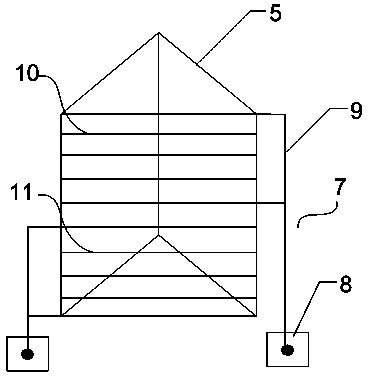

[0024] Example 1, such as Figure 1-4 As shown, an indirect air cooling tower described in the embodiment of the present invention includes a tower body 1 and a cooling fan section 4, the cooling fan section is arranged around the bottom of the tower body, and the cooling fan section includes at least one connected by a radiator 5 and a louver 6 The formed cooling triangle 14, the louvers are connected by the upper window 10 and the lower window 11, the upper window and the lower window are connected to the transmission device 7, the indirect air cooling tower also includes a controller 3, and the transmission device is connected in parallel with the controller Connection; the transmission device includes an actuator 8 and a linkage rod 9 connected with the actuator, and the linkage rod is connected with the blades of the blinds through the crankshaft 17 .

[0025] The structure of the indirect air cooling tower is simple, the cooling fan section is vertically arranged around ...

Embodiment 2

[0030] Example 2, such as Figure 1-5 As shown, an indirect air cooling tower according to an embodiment of the present invention includes a tower body and a cooling fan section, the cooling fan section is arranged around the bottom of the tower body, and the cooling fan section includes at least one cooling triangle formed by connecting radiators and louvers The louvers are composed of an upper window and a lower window. Both the upper window and the lower window are connected to the transmission equipment. The indirect air cooling tower also includes a controller. The transmission equipment is connected in parallel with the controller; the transmission equipment includes the actuator and the The linkage rod connected to the actuator, the linkage rod is connected with the blades of the shutter through the crankshaft. In the technical solution, further, the actuator includes a motor and a gear box connected to the motor, the motor is connected to the controller, and the gear b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com