Non-contact measurement method for sizes of forged pieces

A technology of size and measured objects, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of limited measurement range and low resolution, achieve high-precision measurement, improve system resolution, and avoid the effect of target matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

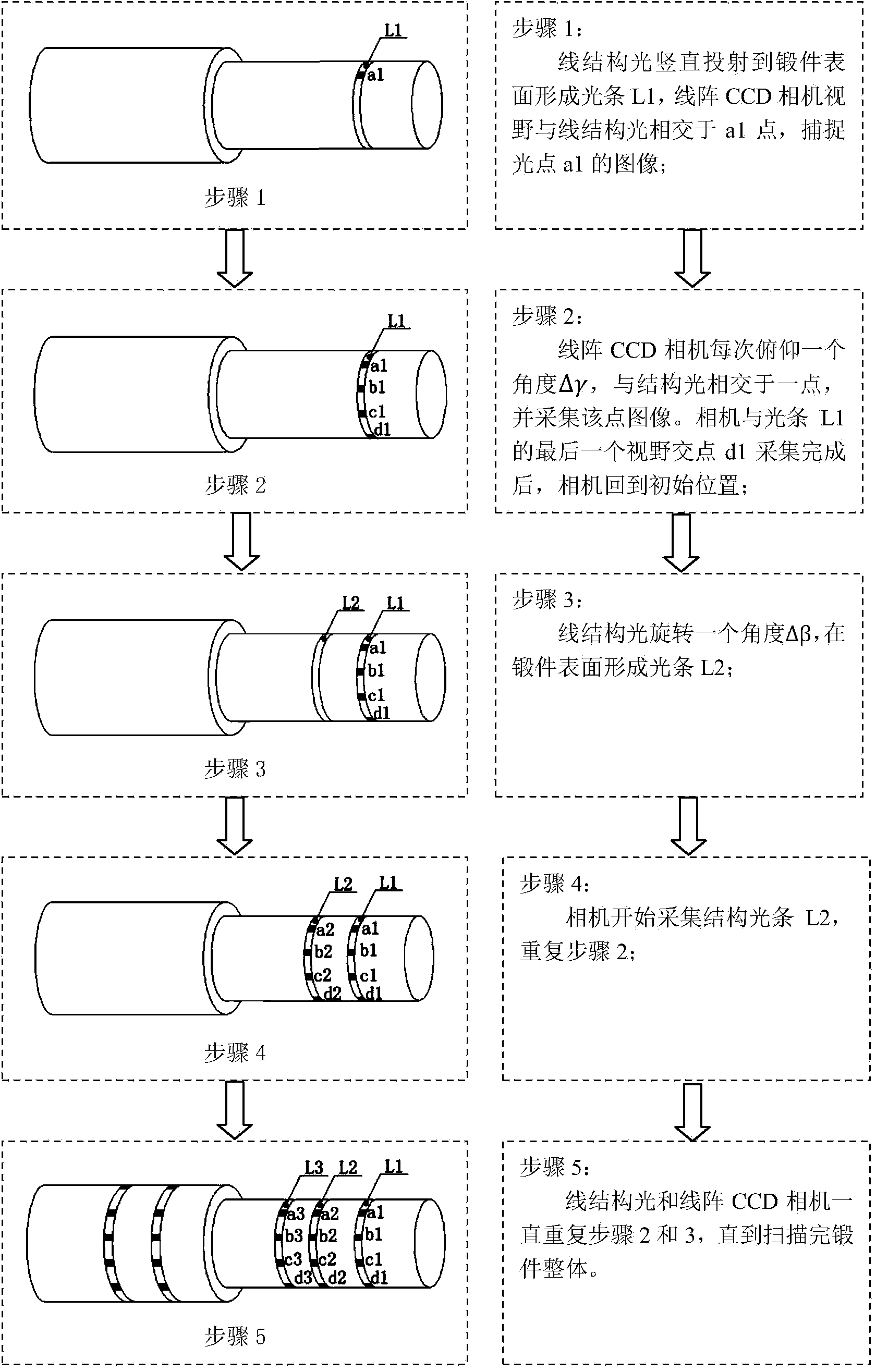

[0032] The specific implementation of the present invention is described in detail with reference to the accompanying drawings and technical solutions:

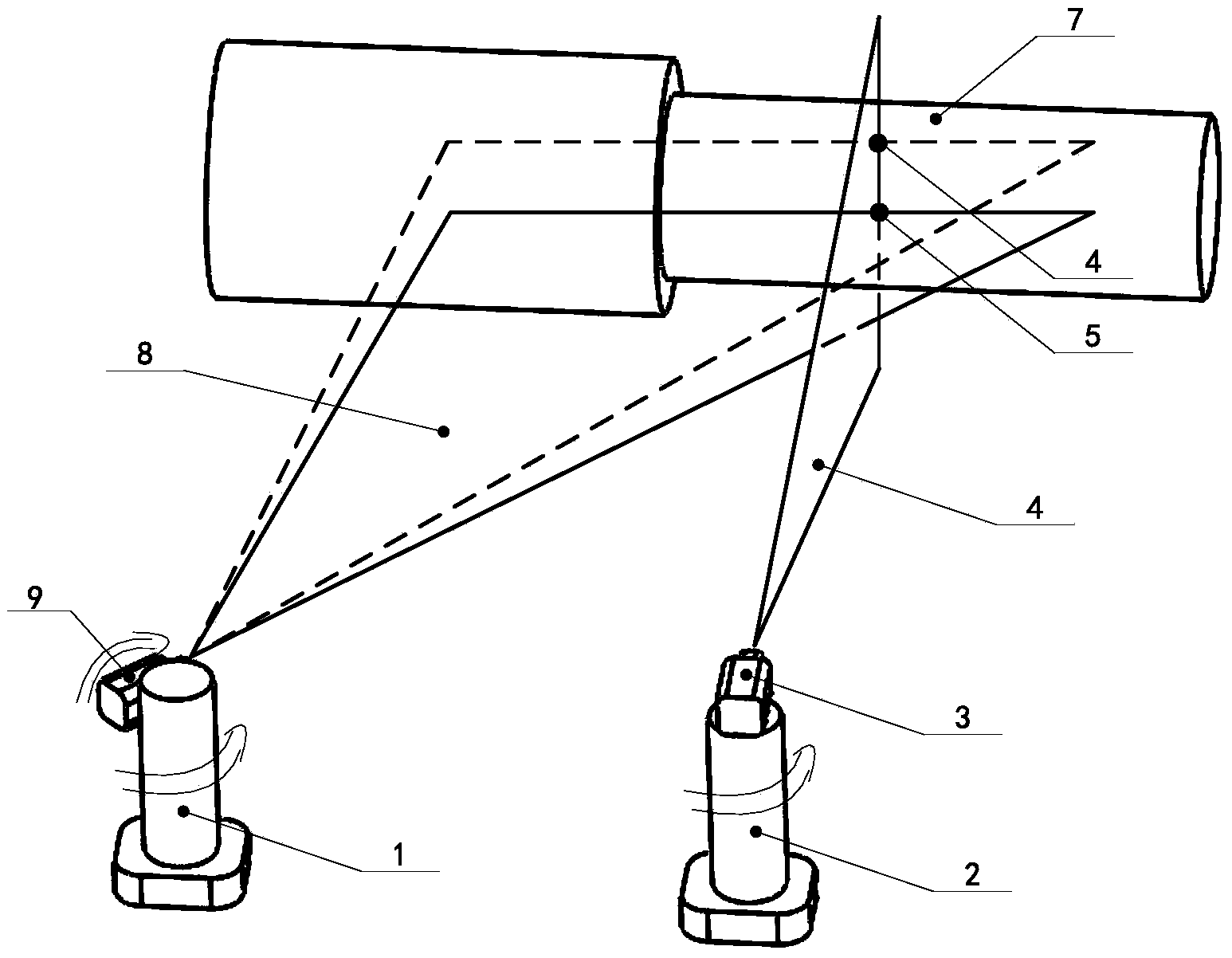

[0033] An on-line scanning measurement device for three-dimensional topography of forgings, such as figure 1 Shown: The linear array CCD camera 8 is installed on the two-degree-of-freedom PTZ 1, the linear structured light projector 3 is installed on the single-DOF PTZ 2, and the two PTZs are separated by a certain distance according to the size requirements of the measured object Place the gimbal 1 and 2, and the distance between them is the so-called baseline distance. The baseline distance should be designed according to the size of the measured object, and the baseline distance has an impact on the measurement accuracy.

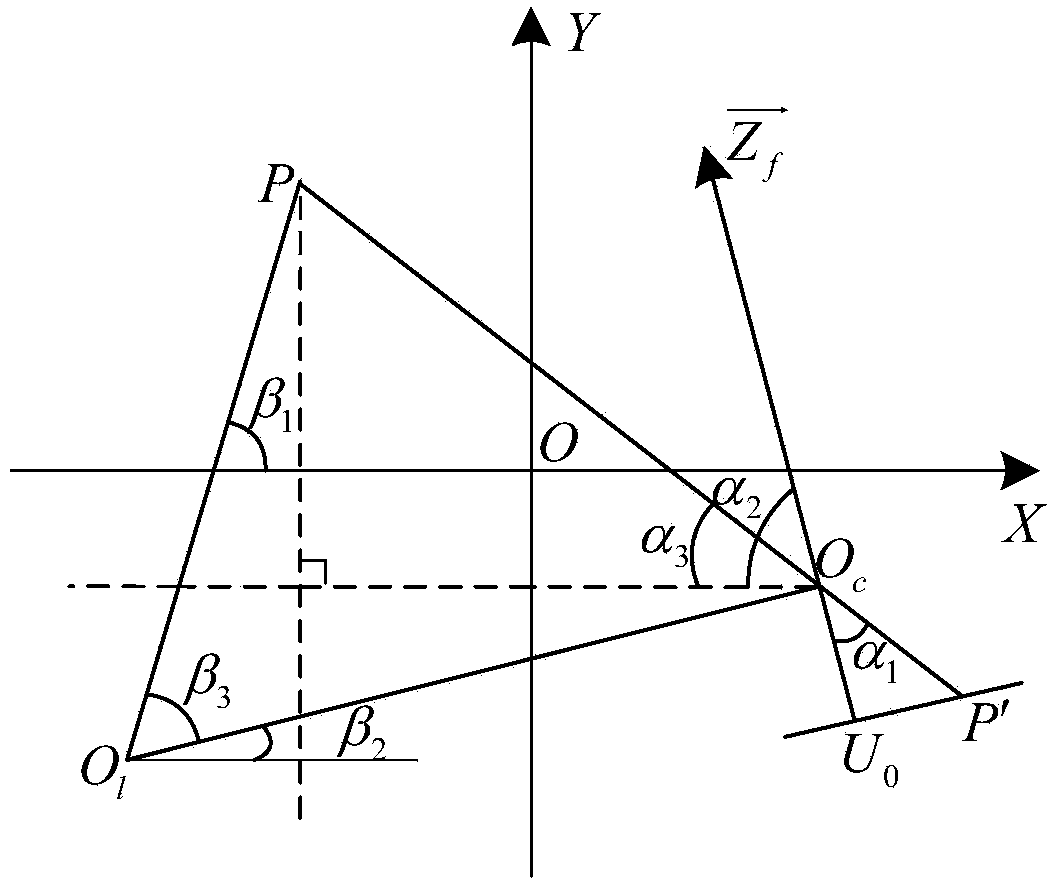

[0034] The measurement system uses the principle of optical triangulation. The 8 optical centers of the linear CCD camera, the optical center of the linear structured light, and the intersection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com