Elastic anisotropic metal matrix thermal barrier coating thickness ultrasonic measurement method

A metal matrix, anisotropic technology, applied in measurement devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as main frequency offset, waveform distortion, inaccurate measurement of thermal barrier coating thickness, etc. Low requirements, low cost, and the effect of solving the large error of coating ultrasonic thickness measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

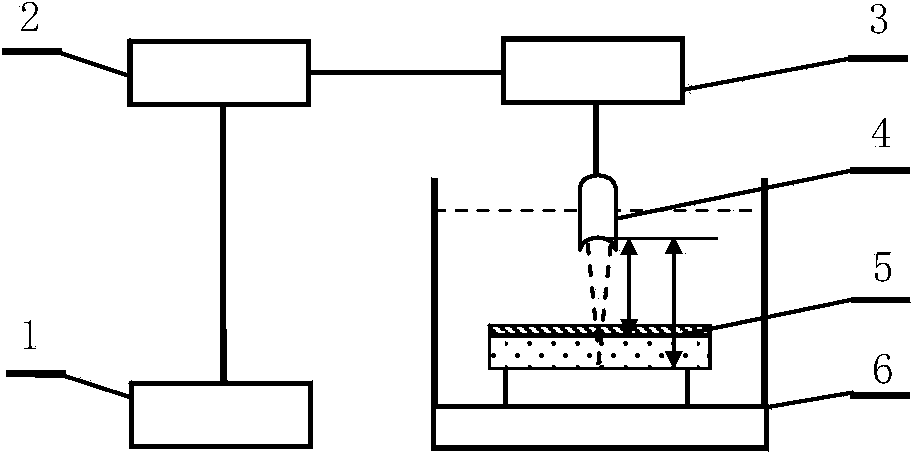

[0031] The ultrasonic measurement method for the thickness of thermal barrier coatings on elastic anisotropic metal substrates adopts figure 1 The ultrasonic pulse echo method C-scan thickness measurement system shown is composed of a SM-J38-300 ultrasonic C-scan device, a nominal 25MHz water immersion point focusing probe, a DPO4O32 digital oscilloscope and a computer. The nominal 60 μm thick nickel-based superalloy substrate YSZ coating sample, the uniform stainless steel substrate YSZ coating sample with a coating thickness of 40-120 μm, and the nickel-based superalloy substrate sample were measured respectively. The measurement steps used are as follows :

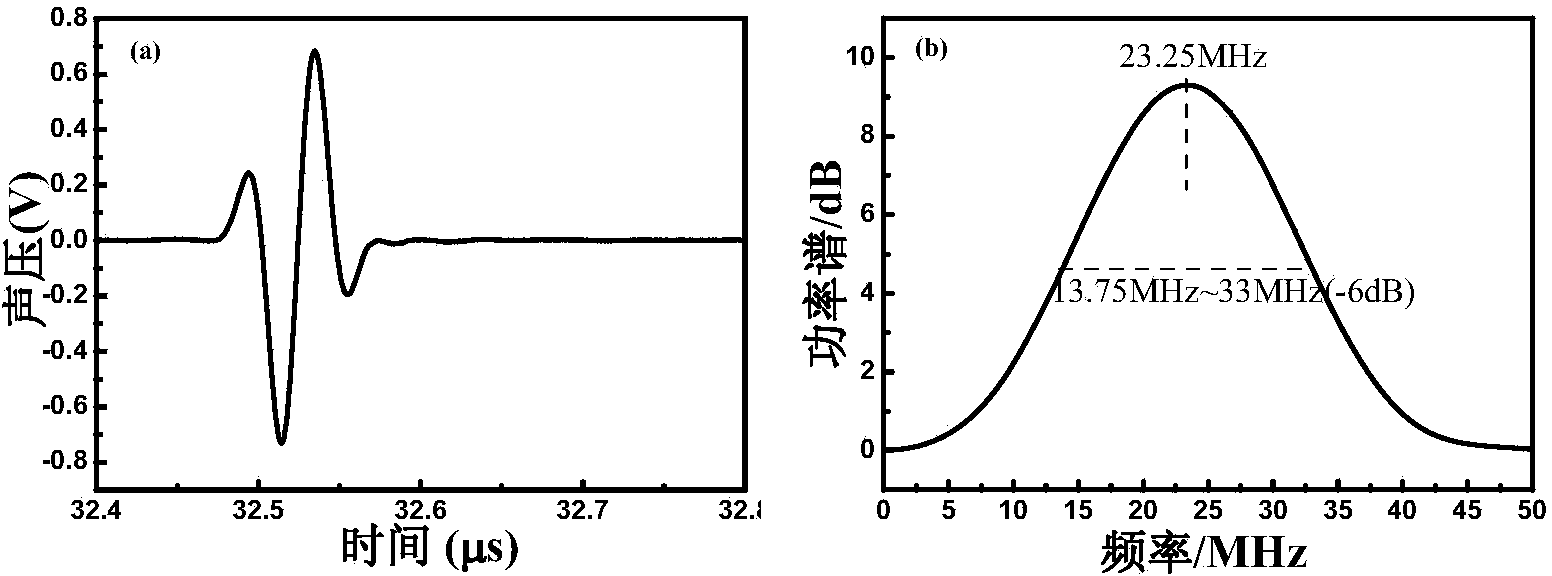

[0032] (1) Calibrate the ultrasonic pulse echo method C-scan thickness measurement system, place the nominal 25MHz water immersion point focusing probe above the nickel-based superalloy substrate sample, adjust the water immersion focusing probe so that the axis of the main sound beam is in line with the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com