Supporting device with ball socket, column socket and plane combined in mass center measurement

A technology of support device and plane phase, applied in the field of support structure, can solve the problems of large friction force, poor centering position accuracy, difficult automatic adjustment of sensors, etc. in the spherical plane support method, so as to shorten the centering process time and improve the measurement accuracy. Accuracy, effect of mutual constraint reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

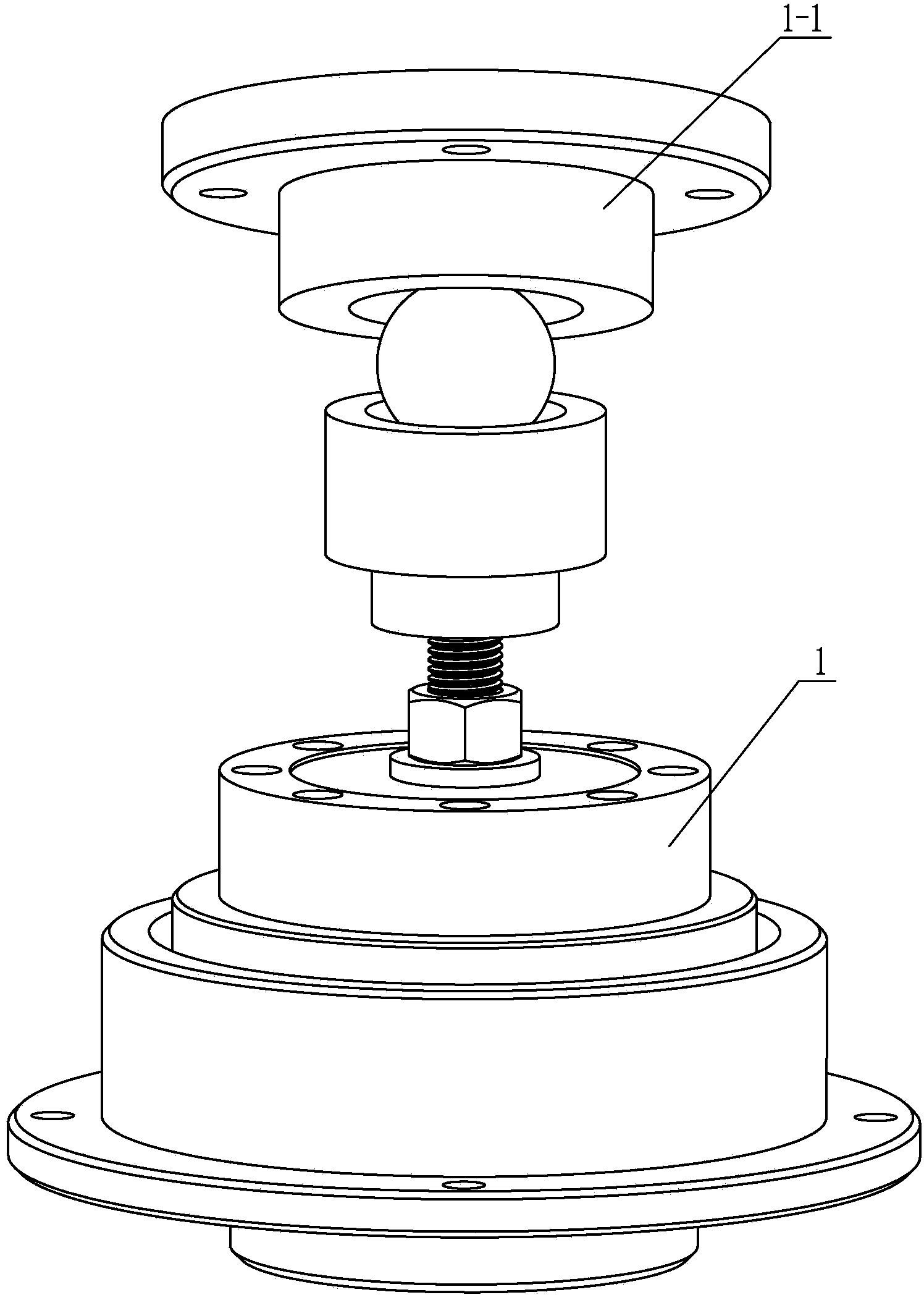

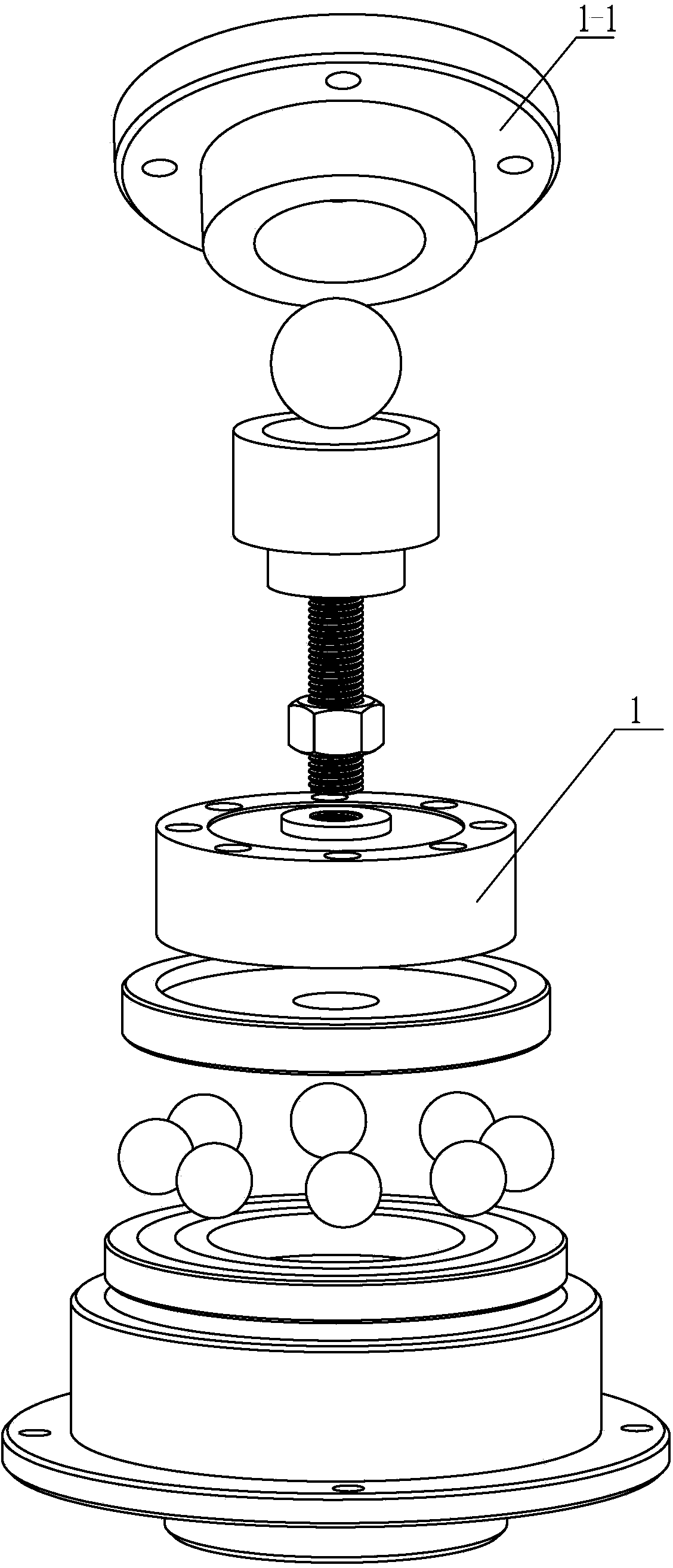

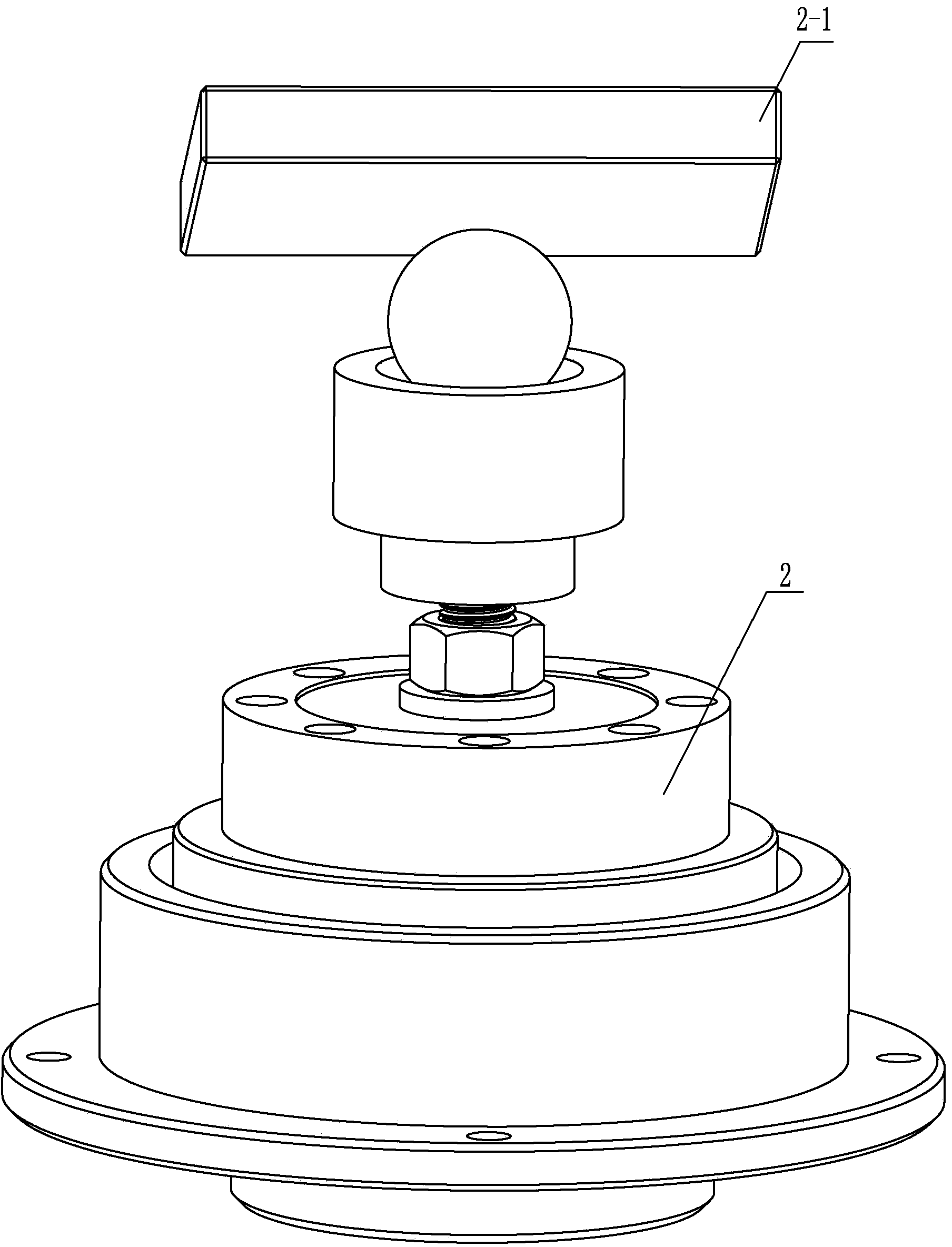

[0024] Specific implementation mode one: combine Figure 4-Figure 6 Illustrate, the support device that combines ball socket, column socket, and plane in the center of mass measurement of this embodiment includes ball socket support structure 1, spherical plane support structure 2 and measurement pedestal 3; Said support device also includes column socket support structure 4, The ball-socket support structure 1, the column-socket support structure 4 and the spherical plane support structure 2 are arranged in an isosceles triangle on the measurement pedestal 3; the column-socket support structure 4 includes a column-socket plate 4-1, a steel ball 4-2, a ball Seat 4-3, load-bearing sensor 4-4, load-bearing sensor tray 4-5 and base 4-7, load-bearing sensor 4-4 is installed on the load-bearing sensor tray 4-5, and load-bearing sensor tray 4-5 is rotatably installed on base 4- 7, the base 4-7 is installed on the measuring pedestal 3, the ball seat 4-3 is detachably installed on the...

specific Embodiment approach 2

[0026] Embodiment 2: The measurement base 3 in this embodiment is a circular base. This setting meets the design requirements and the actual centroid measurement needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 6 To illustrate, the measurement base 3 in this embodiment is a rectangular base. This setting meets the design requirements and the actual centroid measurement needs. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com