Automatic ore-drawing experimental device and experimental method that can adjust the inclination angle of the end wall of the working face

A technology of end wall inclination and experimental equipment, which is applied in the direction of measuring equipment, testing of machines/structural components, instruments, etc., can solve the problems of complicated simulation experiment operation procedures, unrealizable experiments, and low work efficiency, and achieve fast and flexible assembly, Experimental operation is easy to use and has a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

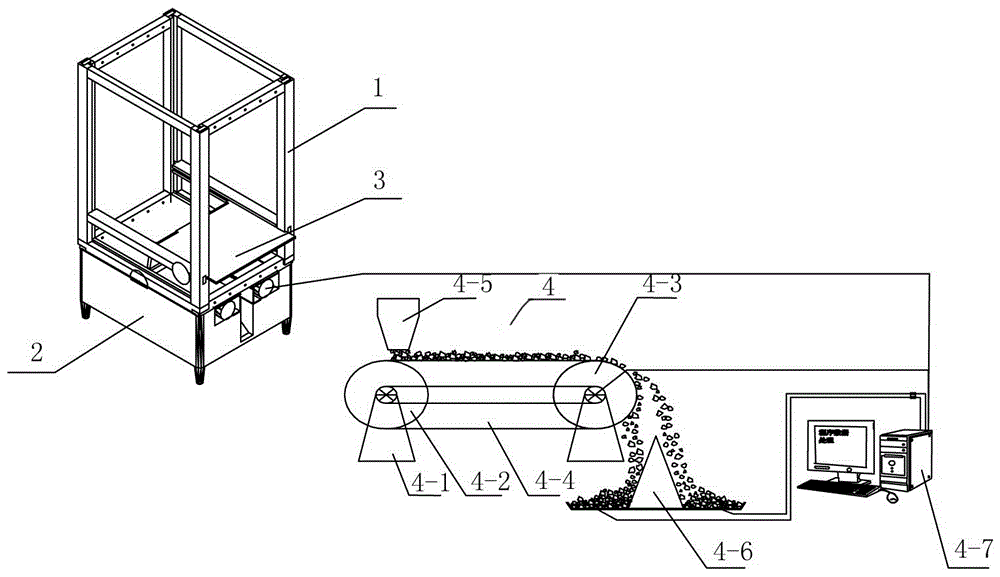

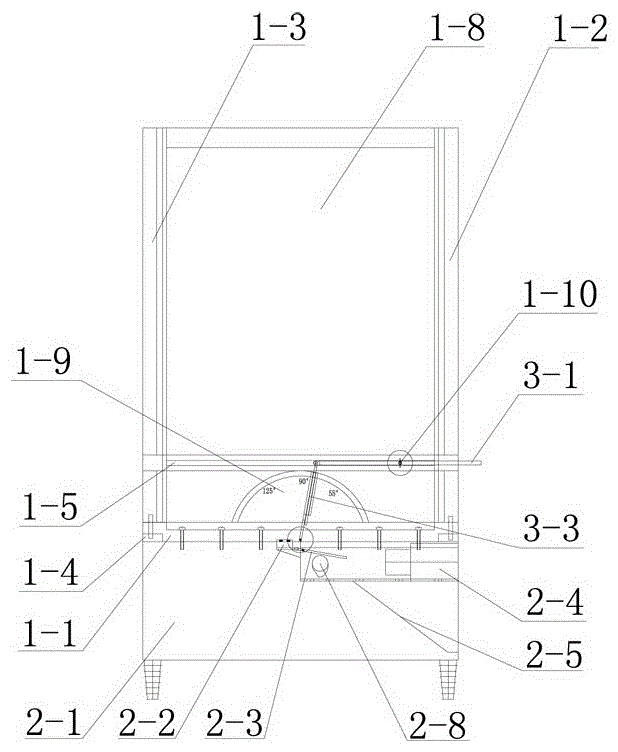

[0039] Such as figure 2 As shown, the automatic ore drawing experiment device capable of adjusting the inclination of the end wall of the working face of the present invention is characterized in that it includes a main ore storage tank 1, and a ore drawing base 2 arranged at the lower part of the main storage tank is set in the main storage tank. The working face inclination adjustment assembly 3 at the lower part of the ore box 1, the ore automatic screening and processing system 4 connected with the ore drawing base,

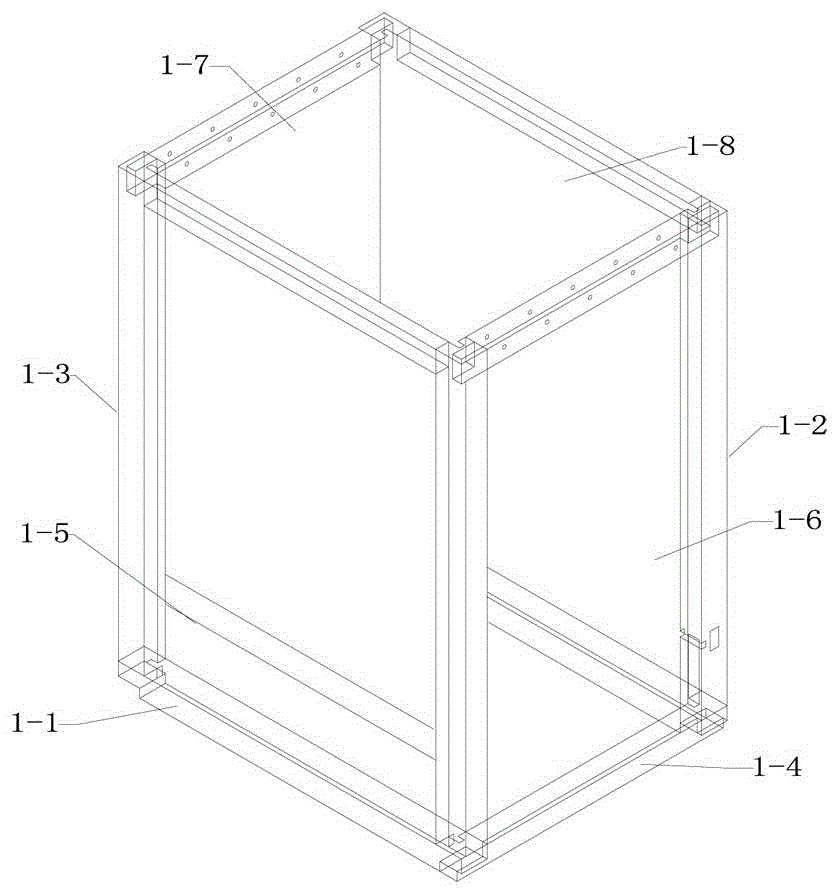

[0040] Such as image 3 , 4 As shown, the main ore storage box 1 includes a ore storage box frame composed of two front pillars 1-2, two rear pillars 1-3, connecting beams 1-4, and bottom supports 1-1, which are set here The two transverse braces 1-5 at the lower part of the ore storage box frame are respectively provided on the front and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com