Control module for automatically adjusting LED working voltage and control method thereof

A technology of LED module and working voltage, which is applied in the direction of electric light source, electric lamp circuit arrangement, lighting device, etc., to achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

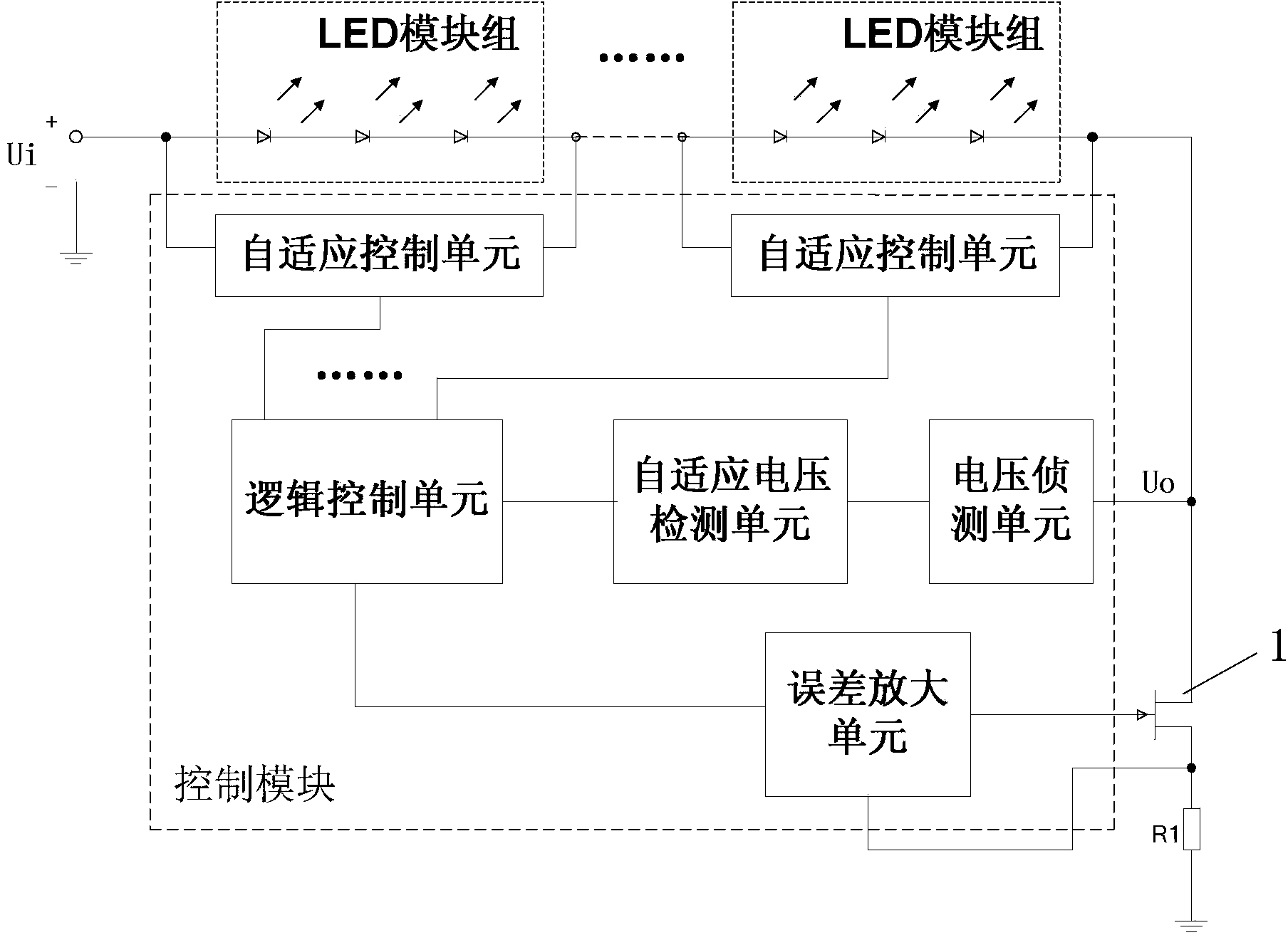

[0019] like figure 1 As shown, a control module suitable for automatically adjusting the LED working voltage includes:

[0020] A plurality of self-adaptive control units connected in parallel with each LED module group, wherein a plurality of LED lamp beads are arranged in the LED module group, and several LED module groups are connected in series; Logic control unit controlled by voltage detection unit.

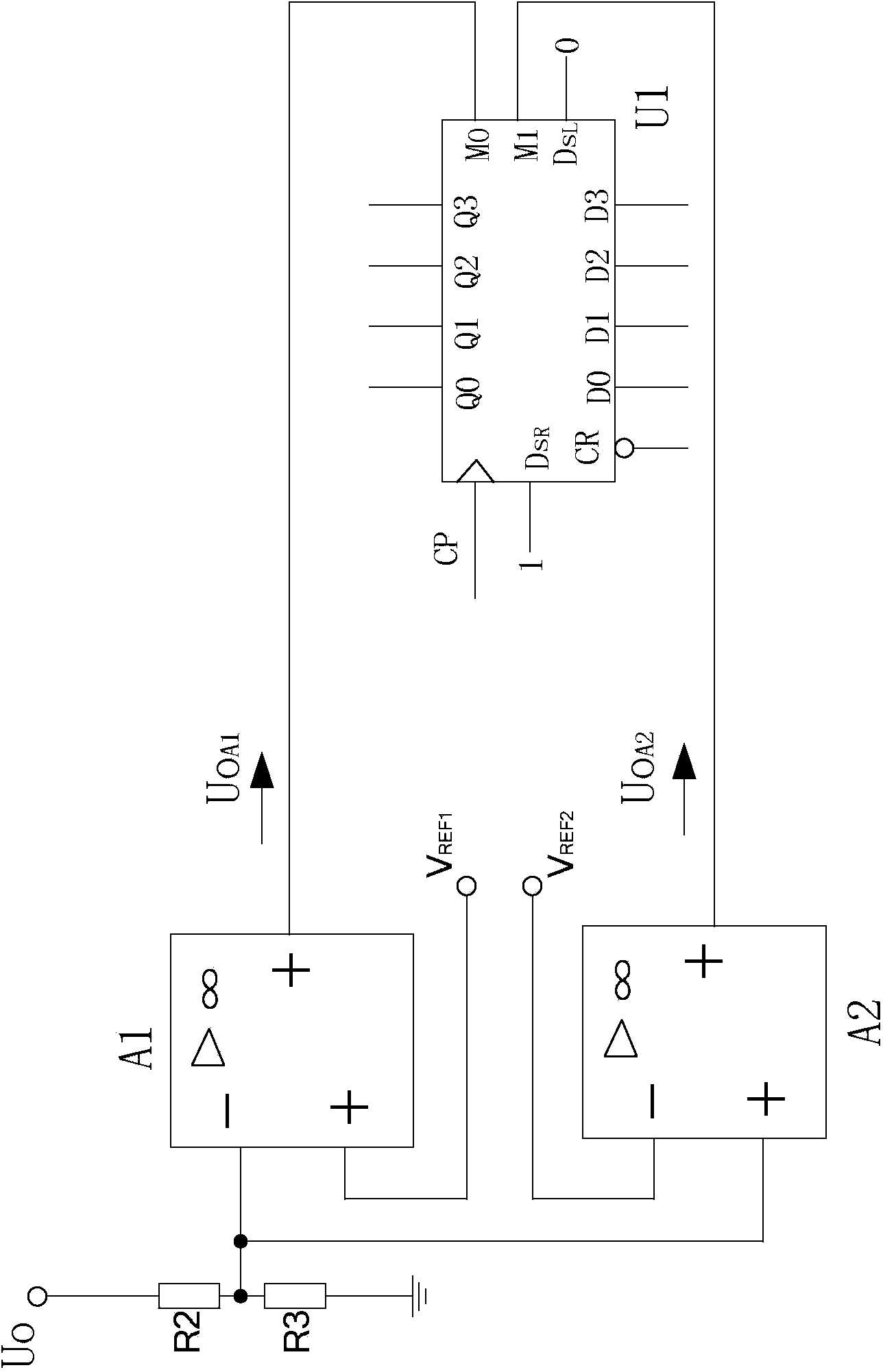

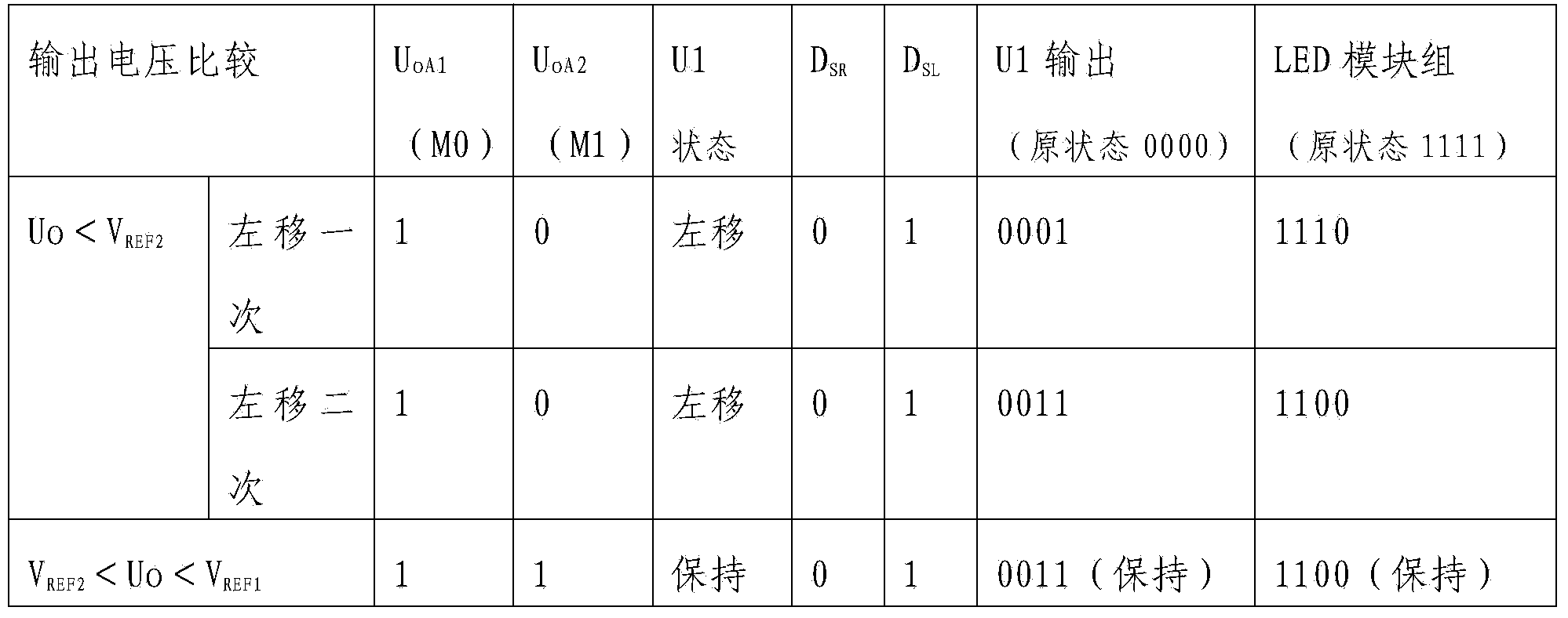

[0021] The adaptive voltage detection unit is used to collect the output voltage of the series LED module group, and according to the output voltage Uo and the upper limit reference voltage V REF1 or lower limit reference voltage V REF2 comparison to obtain a control signal for controlling the logic control unit.

[0022] A logic control unit, which adopts a shift register unit U1, which is adapted to perform left shift or right shift according to the control signal and sequentially output high level or low level to control the adaptive control unit to turn on or Turn o...

Embodiment 2

[0031] like figure 1 and figure 2 As shown, embodiment 2 based on embodiment 1 is a control method for a control module suitable for automatically adjusting the LED operating voltage, wherein the control module includes: several self-adaptive Control unit, adaptive voltage detection unit, logic control unit.

[0032] The control methods include:

[0033] The adaptive voltage detection unit collects the output voltage of the series LED module group, and according to the output voltage Uo and the preset upper limit reference voltage V REF1 or lower limit reference voltage V REF2 comparison to obtain a control signal for controlling the logic control unit.

[0034] The logic control unit adopts a shift register unit U1, which is suitable for shifting left or right according to the control signal and sequentially outputting high level or low level to control the adaptive control unit to be turned on or off , so that the corresponding LED module group goes out or lights up. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com