Cutting machine

A cutting machine and engine technology, which is used in cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of difficulty in fully improving cutting operation efficiency, trouble in removing accumulated soil and mud, and heavier weight at the end of the cutting machine. , to achieve the effect of easy anti-involvement, lightening of the burden, and easy discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments for carrying out the present invention will be described in detail below based on the drawings.

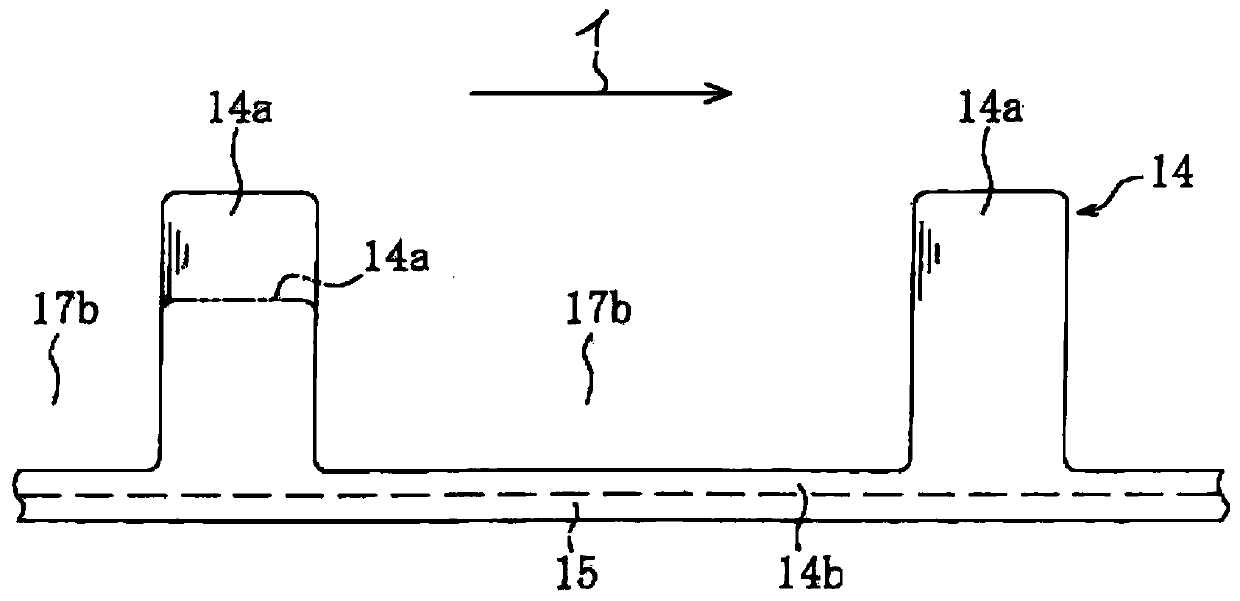

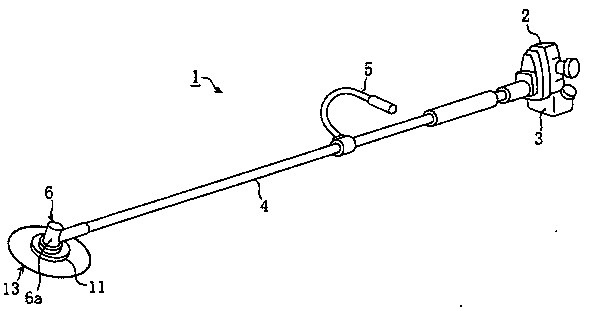

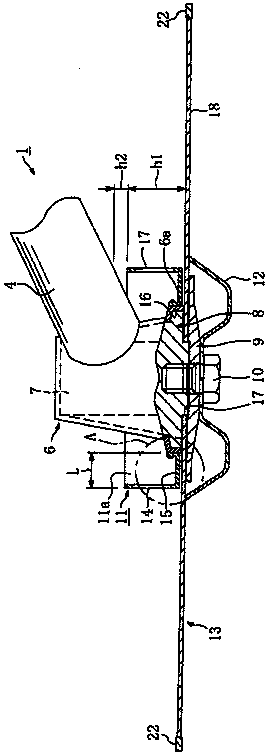

[0027] Figure 1 to Figure 5 An embodiment of the cutting machine according to the present invention is shown. Such as figure 1 As shown, the cutting machine 1 is equipped with an engine 2 as a rotary drive part driven by gasoline in a fuel tank 3, and a handle 5 connected to the rotation shaft of the engine 2 and provided at a predetermined position in the longitudinal direction. The connecting rod 4 and the bearing cover 6 provided at the end of the connecting rod 4 , on which a rotary blade 13 such as a blade saw is mounted, and an undercut prevention part 11 is integrally fixed to the lower end of the outer peripheral surface.

[0028] Then, it is driven by the engine 2, and its rotating shaft rotates at a predetermined speed, and the rotation of the rotating shaft is transmitted to the bearing part 7 in the bearing cover plate 6 through the connecting sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com