Novel waste heat/live steam composite evaporator

A raw steam and composite technology, which is applied in the field of new waste heat/raw steam composite evaporators, can solve the problems of short effective operation time, large liquid storage, low equipment efficiency, etc., so as to prolong the heat exchange time and reduce the COD content. , to avoid the effect of excessive heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

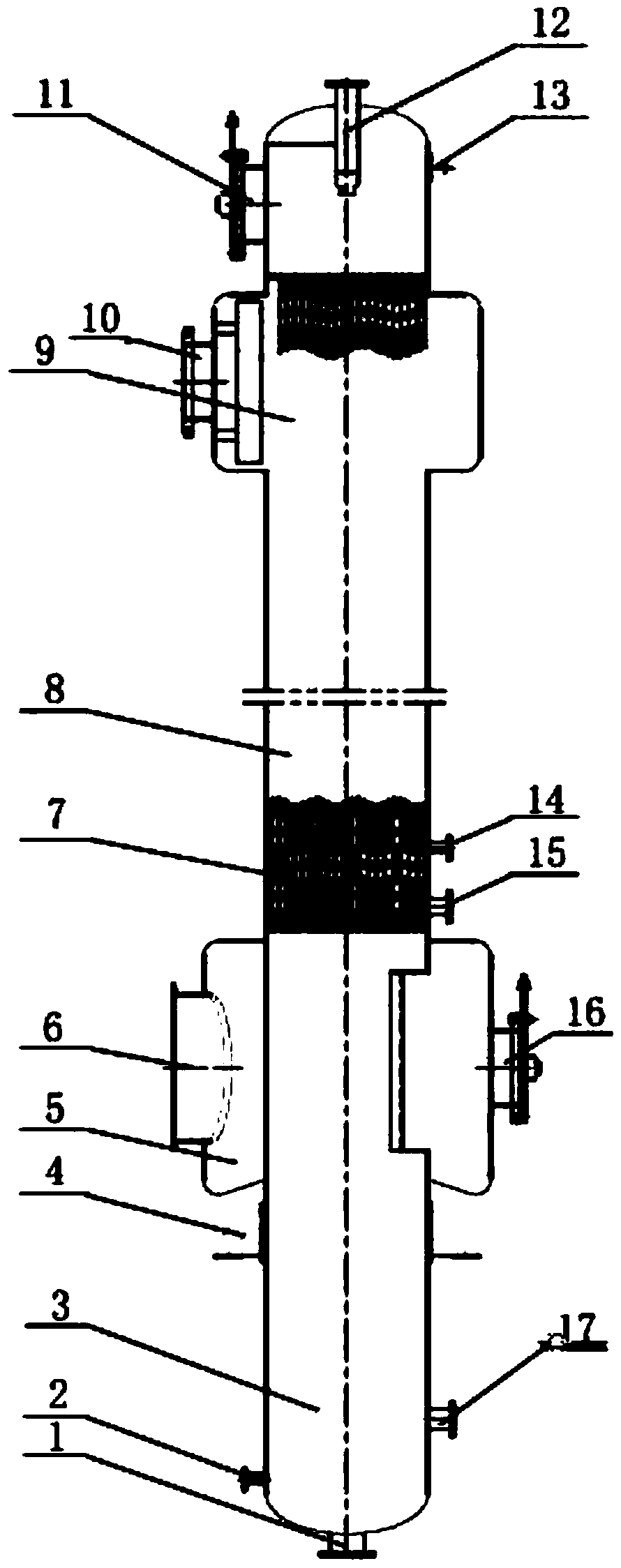

[0014] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a novel waste heat / generated steam composite evaporator proposed by the present invention.

[0015] refer to figure 1 , a novel waste heat / generated steam composite evaporator proposed by the present invention includes a cavity, which includes a gas collection chamber, a heating chamber 8, an upper separation chamber 5, and a lower separation chamber 3, and the outer wall of the cavity is provided with There are supports 4 and lifting lugs 13, which are convenient for fixing the position of the cavity;

[0016] The gas collection chamber is located on the top of the cavity, which is used to collect waste heat / generated steam. The gas collection chamber includes a gas collection area and an expansion area 9 from top to bottom. 12 is used to evenly distribute the medium to be concentrated. The cavity is provided with a manhole 11 on the side wall of the gas collection area, which is convenient ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap