A filter element quick disassembly structure

A filter and filter element technology, which is applied in the field of quick disassembly and assembly of filter elements, can solve problems such as long maintenance time, high labor intensity, and stainless steel bolts cannot be found, so as to save time and effort in disassembly and assembly, reduce labor intensity, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

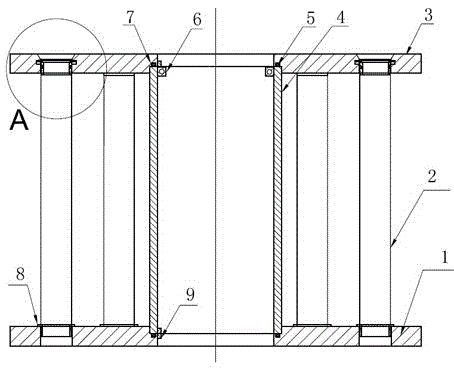

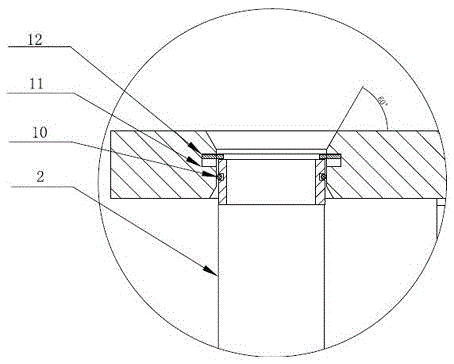

[0019] Such as figure 1 , figure 2 A quick disassembly and assembly structure of a filter element is shown, which includes an upper tray 3, a support cylinder 4, and a lower tray 1 connected in sequence, and is fixed on the upper tray 3 through the filter element installation holes arranged on the upper tray 3 and the lower tray 1. Several filter elements 2 between the lower tray 1; the filter element installation hole 13 of the upper tray 3 is provided with an annular groove 11, and a retaining ring 12 for earless elastic holes is arranged in the annular groove 11.

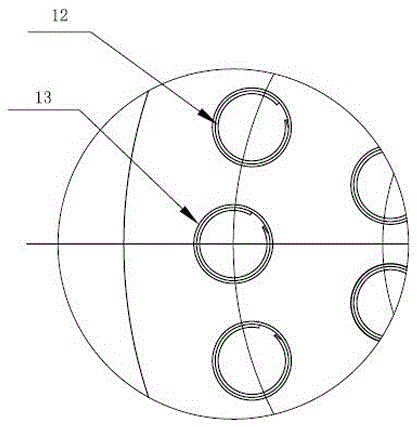

[0020] The upper tray 3, the lower tray 1, and the support cylinder 4 are all hollow cylindrical structures, and the cylindrical end faces of the upper tray 3 and the lower tray 1 of the filter element installation hole 13 are evenly spaced; image 3 As shown in , this solves the installation problem of multi-filter elements, takes up less space, and has a more reasonable structure.

[0021] Positioning blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com