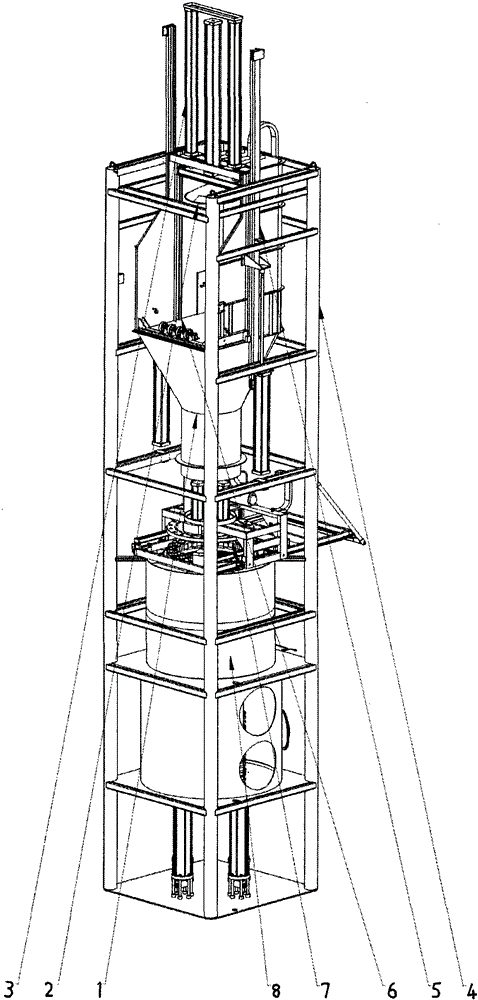

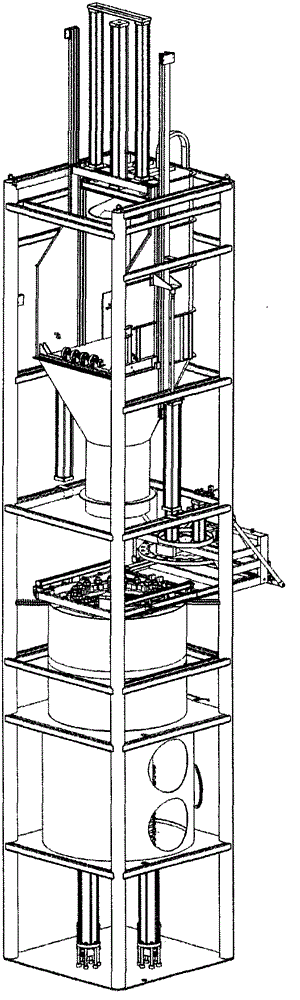

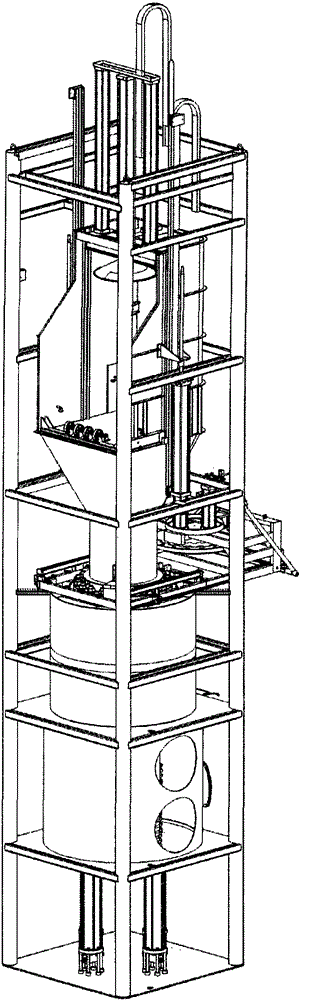

Feeding and pressing mechanism of a steam explosion machine

A technology of steam explosion machine and explosion cavity, which is applied in the field of feeding equipment, can solve problems such as difficulty in adapting to feeding requirements, blockage of light materials, large power reserve, etc., and achieve energy saving of steam, direct action and simple structure Effect

Active Publication Date: 2017-04-05

于政道 +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The screw feeder, vacuum feeding, inertial feeding and other methods in the prior art are difficult to meet the above feeding requirements

The screw feeder is suitable for the continuous and average feeding process, and it needs a large power reserve to realize the compaction of the feeding material; the vacuum feeding method is very sensitive to the physical state of the material, and generally can only be used for powdery homogeneous materials. It is difficult to form a vacuum pressure difference for fluffy materials; inertial feeding depends on the initial velocity of the material itself, and the force is poor, especially for light materials that are prone to blockage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] The supporting material feeding and pressing mechanism on the LB-1500 type numerical control continuous steam explosion machine is the specific implementation of the above invention. The mechanism can feed 2 to 3 cubic meters at a time, the up and down travel distance is 1.5 meters, and the pressing force of the pressing hammer is about 20 kN, which can meet the feeding requirements of most biomass materials.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a material feeding and pressing mechanism matching with a steam explosion machine. The material feeding and pressing mechanism is a material conveying device. The material feeding and pressing mechanism runs up and down in a track and cooperates with the steam explosion machine. The mechanism can be inserted into the explosion chamber of the steam explosion machine in running as needed, and a pneumatic material hammer is arranged in the mechanism, so a material with bad fluidity can be rapidly inserted into the explosion chamber of the steam explosion machine in order to realize forced feeding. The mechanism can effectively shield the pollution of the material to a sealing assembly during feeding, and can also guarantee the normal work of the steam explosion machine. Additionally, the mechanism further presses the material, so the energy consumption of steam is saved, and the equipment production capacity is improved.

Description

technical field [0001] The invention relates to a material feeding device matched with a steam explosion machine, which is a material conveying device. Background technique [0002] The steam explosion machine is a kind of equipment used for biomass pretreatment. The objects it deals with include crop stalks, energy crops, organic waste, etc. There are many kinds of these materials, most of which are fluffy, low-density, poor fluidity biomass materials, accompanied by dust, impurities, and powder, so the requirements for the feeding mechanism of the steam explosion machine are relatively special. First of all, the steam explosion material enters sequentially, and the influx of large-volume flow of material in a short period of time may easily cause blockage of the material inlet, which is not conducive to the automatic and continuous operation of the steam explosion machine. Secondly, the material falls into the explosion chamber through the sealing inlet of the upper cove...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J3/02

Inventor 张百良于政道杨世关徐桂转宋安东

Owner 于政道

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com