A large-diameter flotation column medium ore cyclone device and tailings cyclone discharge device

A swirl device and flotation column technology, applied in swirl device, flotation, solid separation, etc., can solve the problems of poor swirl flotation effect of medium ore, less chance of countercurrent collision of ore slurry, and inability to discharge tailings in time. , to solve the blockage, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

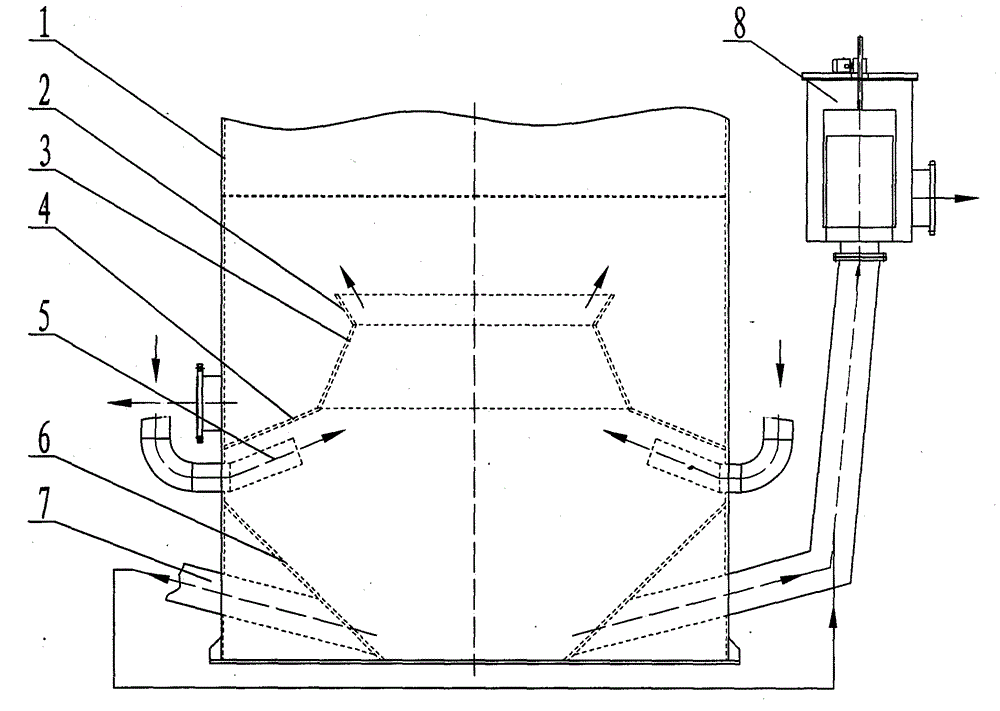

[0013] As shown in the figure: the medium ore slurry enters the bottom of the cylinder 1 through the medium ore feeding pipe 5, and after diverging along the lower cone 4, a part of it is sprayed on the inner wall of the middle cone 3, and the lighter particles rise rapidly, and the heavier particles Rapidly descend to the bottom of the column to become tailings, form a swirling state on the bottom cone 6, and flow through the tailings discharge pipe 7 to the tailings discharge barrel 8 in time to swirl and discharge; the other part of the slurry is sprayed through the upper cone 2 On the side wall of the column, fully countercurrently collide with the falling medium ore slurry for mineralization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com