grinding wheel

A grinding wheel and grinding tool technology, which is used in grinding machines, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc. Vibration lines and other problems, to achieve the effect of reducing grinding resistance, suppressing vibration, and eliminating vibration lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

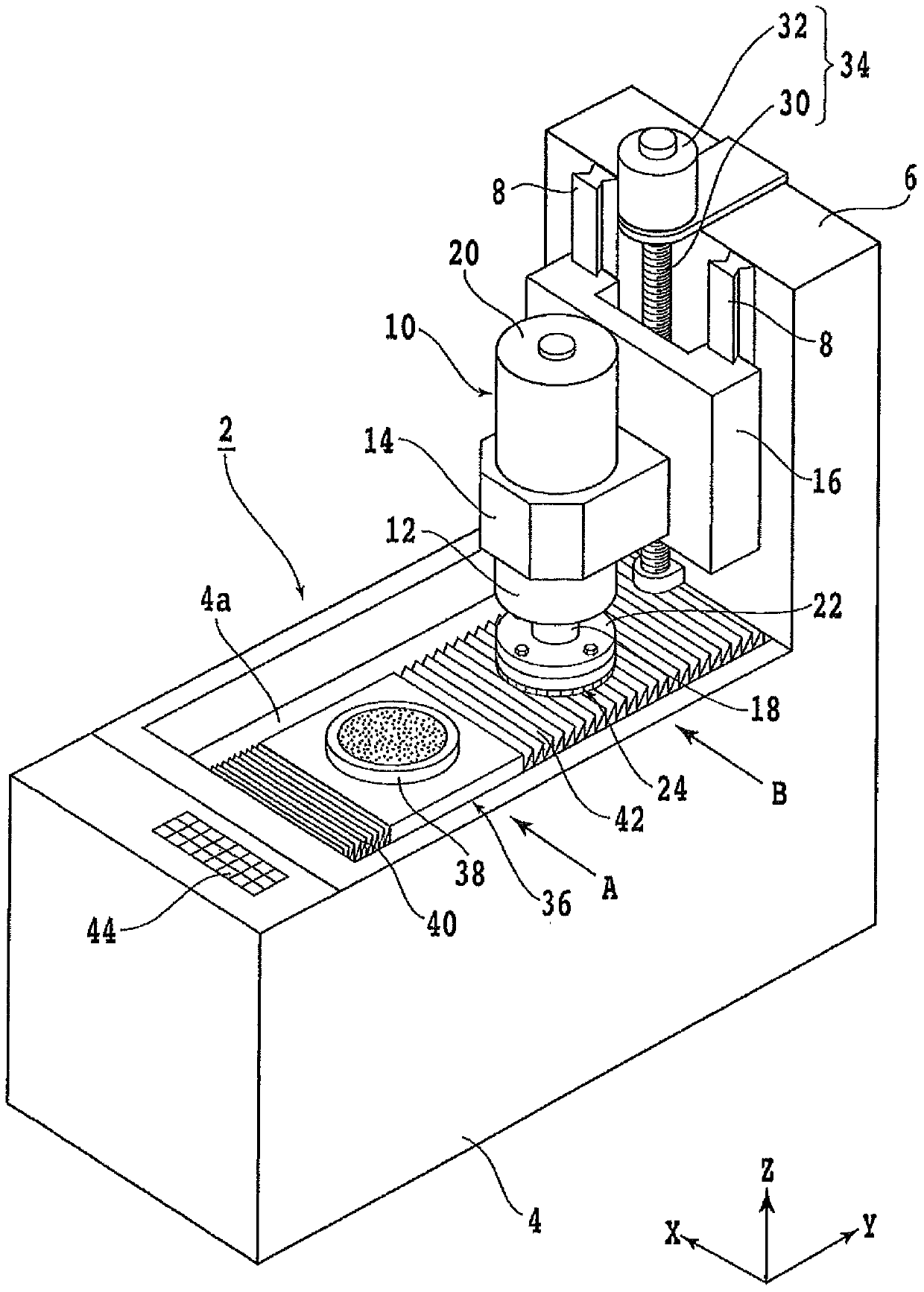

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. refer to figure 1 , shows an external perspective view of a grinding device 2 provided with the grinding wheel of the present invention. Reference numeral 4 is a base of the grinding device 2 , and a column 6 is erected behind the base 4 . A pair of guide rails 8 extending in the vertical direction are fixed to the column 6 .

[0031] A grinding unit (grinding member) 10 is installed so as to be movable in the up and down direction along the pair of guide rails 8 . The grinding unit 10 has a headstock 12 and a support portion 14 that holds the headstock 12 , and the support portion 14 is attached to a moving base 16 that moves vertically along the pair of guide rails 8 .

[0032] The grinding unit 10 includes: a main shaft 18 rotatably accommodated in a headstock 12; a motor 20 which drives the main shaft 18 to rotate; a wheel base 22 fixed to an end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com