Stainless steel pipe polishing device

A stainless steel tube and polishing device technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of labor occupancy, inability to polish operations, low polishing efficiency, etc. Good effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

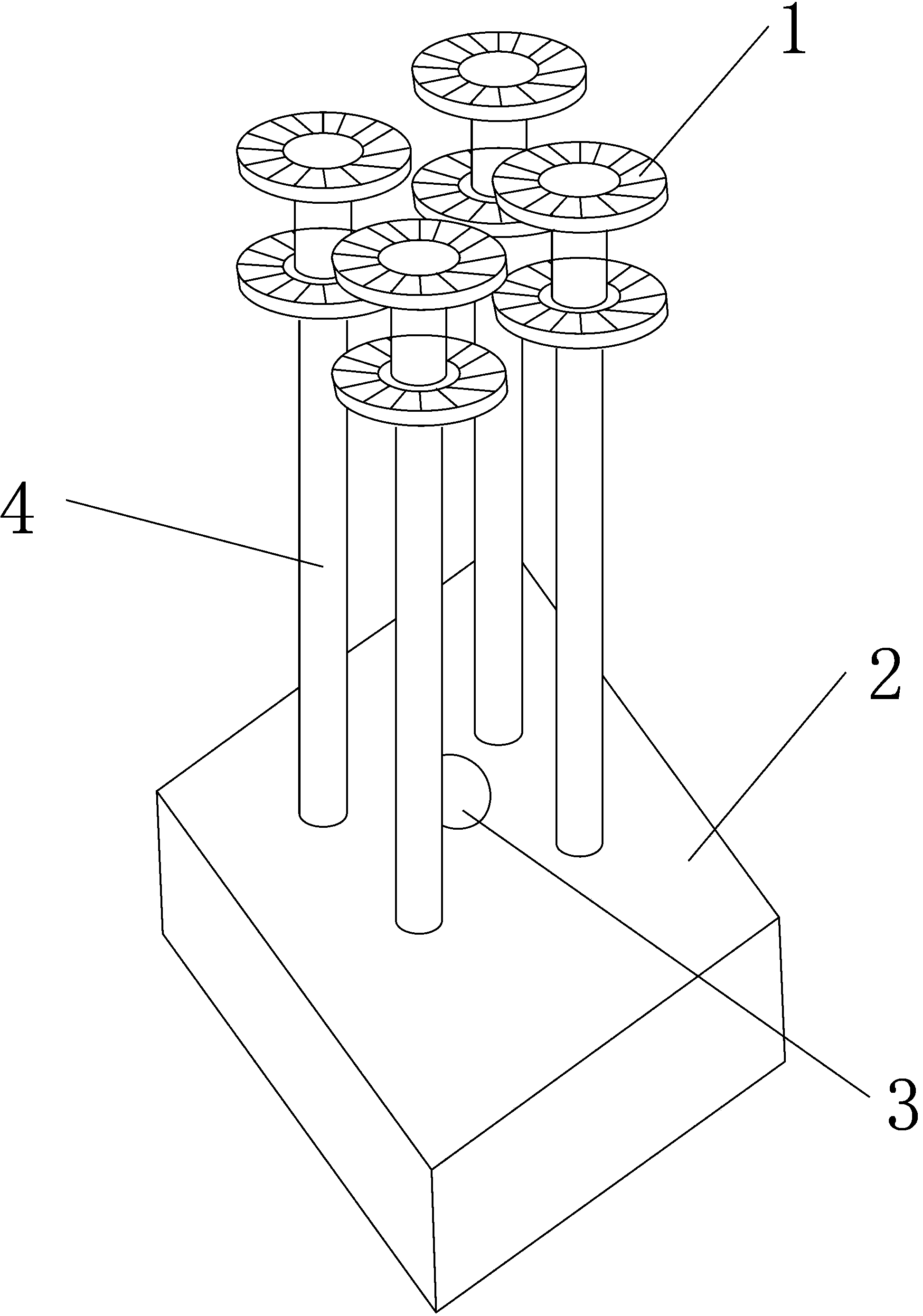

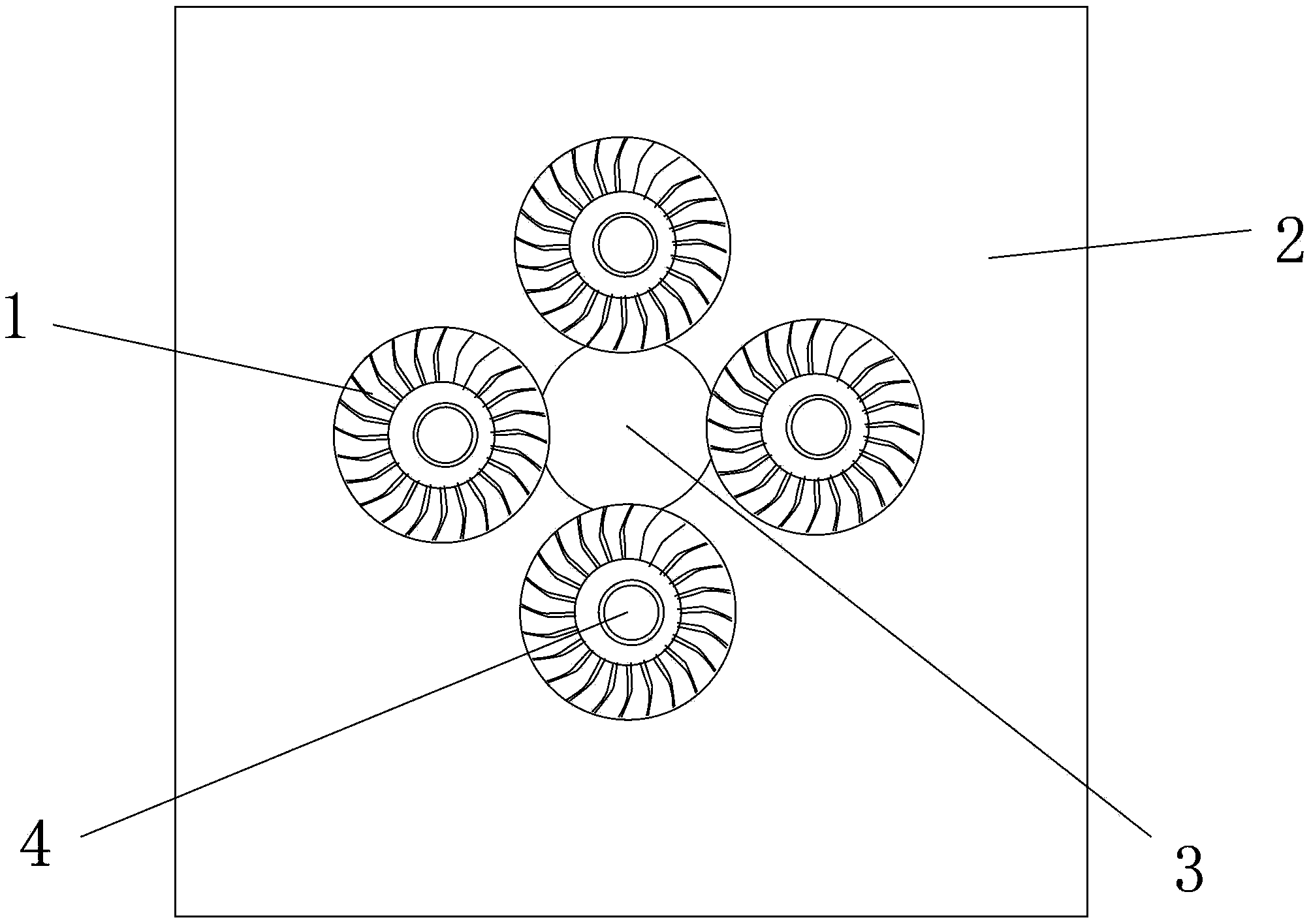

[0014] Embodiment: As shown in the figure, a polishing device for a stainless steel tube includes a polishing wheel 1, a motor 2, a perforation 3 and a rotating shaft 4; The central point of the connection position is provided with a perforation 3 for stainless steel pipes to pass through; at least one polishing wheel 1 is installed on each rotating shaft 4, and the polishing wheels 1 are surrounded by a square and there are intervals between them.

[0015] The rotation direction of the rotating shaft 4 is clockwise or counterclockwise.

[0016] Preferably, two polishing wheels 1 are installed on the rotating shaft 4, such as figure 1 shown. According to actual production needs, the number of polishing wheels on each rotating shaft 4 can be adjusted; the more the number of polishing wheels, the better the polishing effect, but it will reduce the speed of the stainless steel tube passing through the polishing area, thereby affecting the overall work efficiency.

[0017] Since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com