Lift type flat bottom malt-steeping tank

A lift-type malting trough technology, applied in the direction of malt preparation, beer brewing, biochemical equipment and methods, etc., can solve the problems of unreliable use, layout influence, increased noise, etc., and achieve convenient and reliable use, Guaranteed sealing performance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

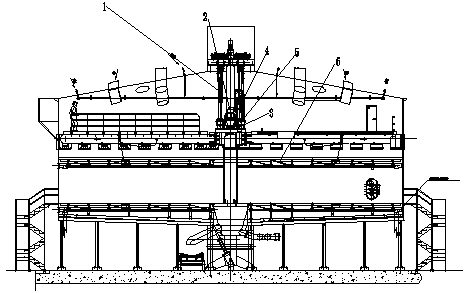

[0022] The invention comprises a leveling machine, on which a lifting device is connected to make the leveling machine move up and down, a sieve plate is arranged at the lower part of the leveling machine, a number of through holes are opened on the sieve plate, and a sieve plate communicating with the through holes of the sieve plate is arranged under the sieve plate. The air inlet pipe and the water inlet pipe; the sieve plate and the bracket supporting the sieve plate are of an integrated structure, and the lower part of the bracket is provided with a bracket supporting the sieve plate and the bracket.

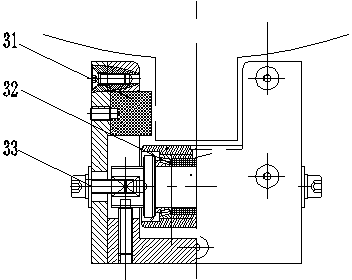

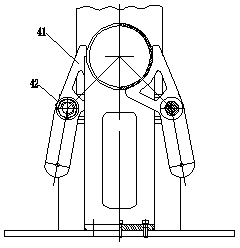

[0023] The lifting device includes a lifting shaft sleeved outside the central pillar, rail limiters are provided on both sides of the lifting shaft, and the structure of the rail limiter is: a through hole is provided to embrace the lifting shaft, and a through hole is provided in the through hole Bearings supporting the guide lift shaft and wear blocks in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com