Dam reinforcement method

A dam and dam body technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve problems such as failure to fundamentally prevent danger, damage to the dam body structure, collapse of the outer dam body, etc. Good impermeability and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

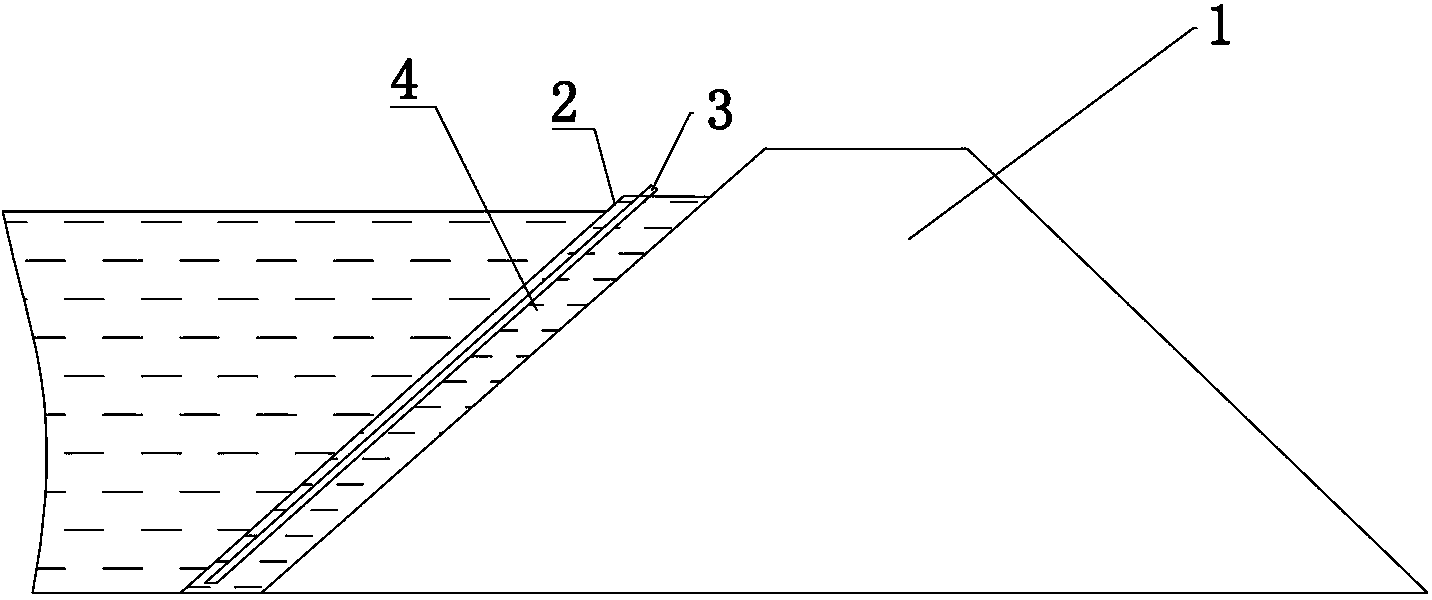

[0038] Such as figure 1 As shown, the dam body 1 in the present embodiment, the shroud 2, and the grouting pipe 3.

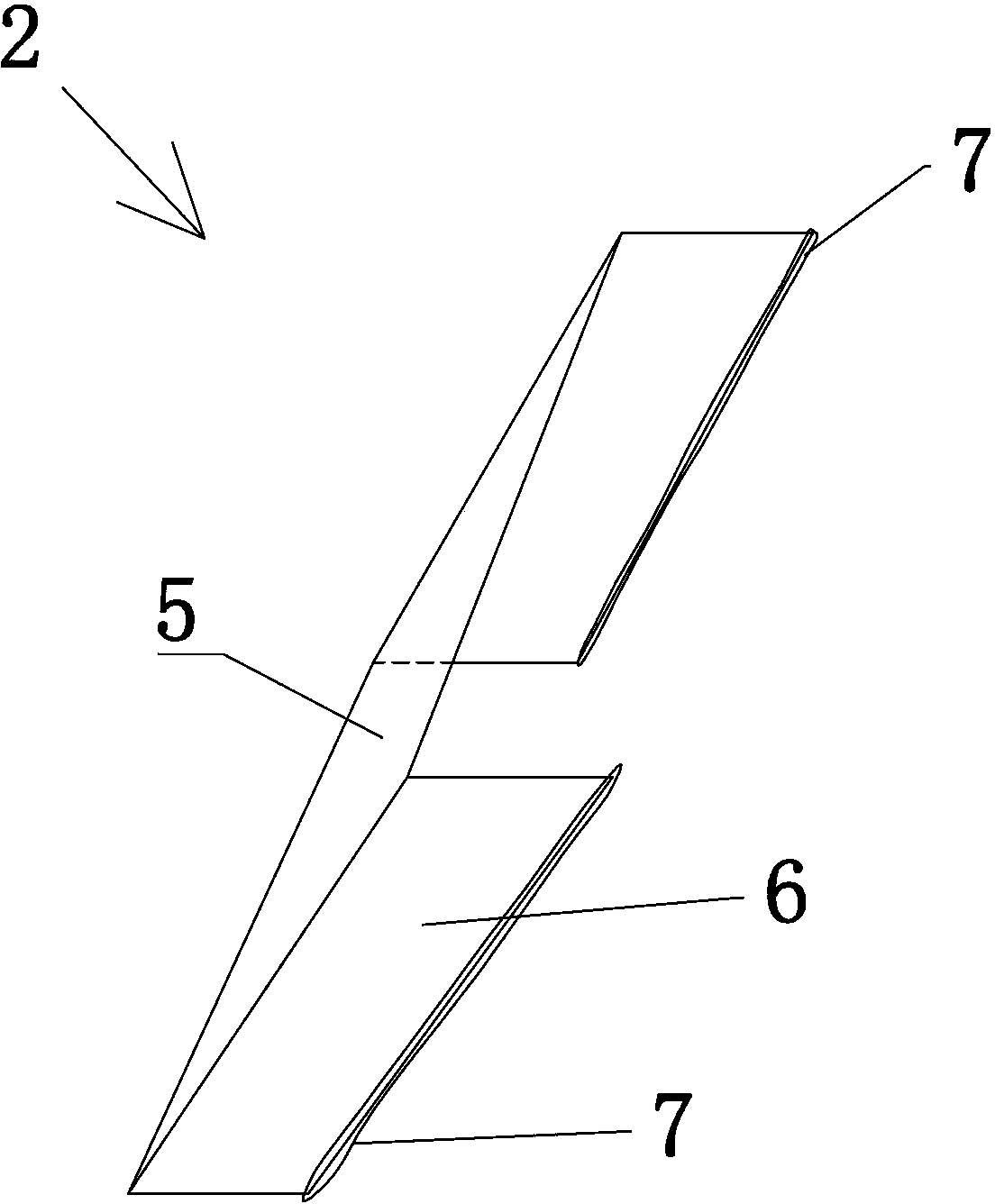

[0039] Such as image 3 and Figure 4 As shown, the enclosure 2 made according to the shape of the outer side of the dam body includes three panels, which are respectively inclined panels 5 and side panels 6 on the front and rear sides. When the inclined panels 5 are parallel to the outer side of the dam body, the side panels 6 Just perpendicular to the outer surface of the dam body, the edge of the side panel 6 suitable for fitting with the dam body is provided with a sealing strip 7, and the sealing strip 7 is suitable for sealing against the side surface of the dam body; A layer of plastic film is pasted on the inner surface, the material of the enclosure 2 can be plastic or metal, and the width of the side panel 6 (including the sealing strip) is 5-10 cm.

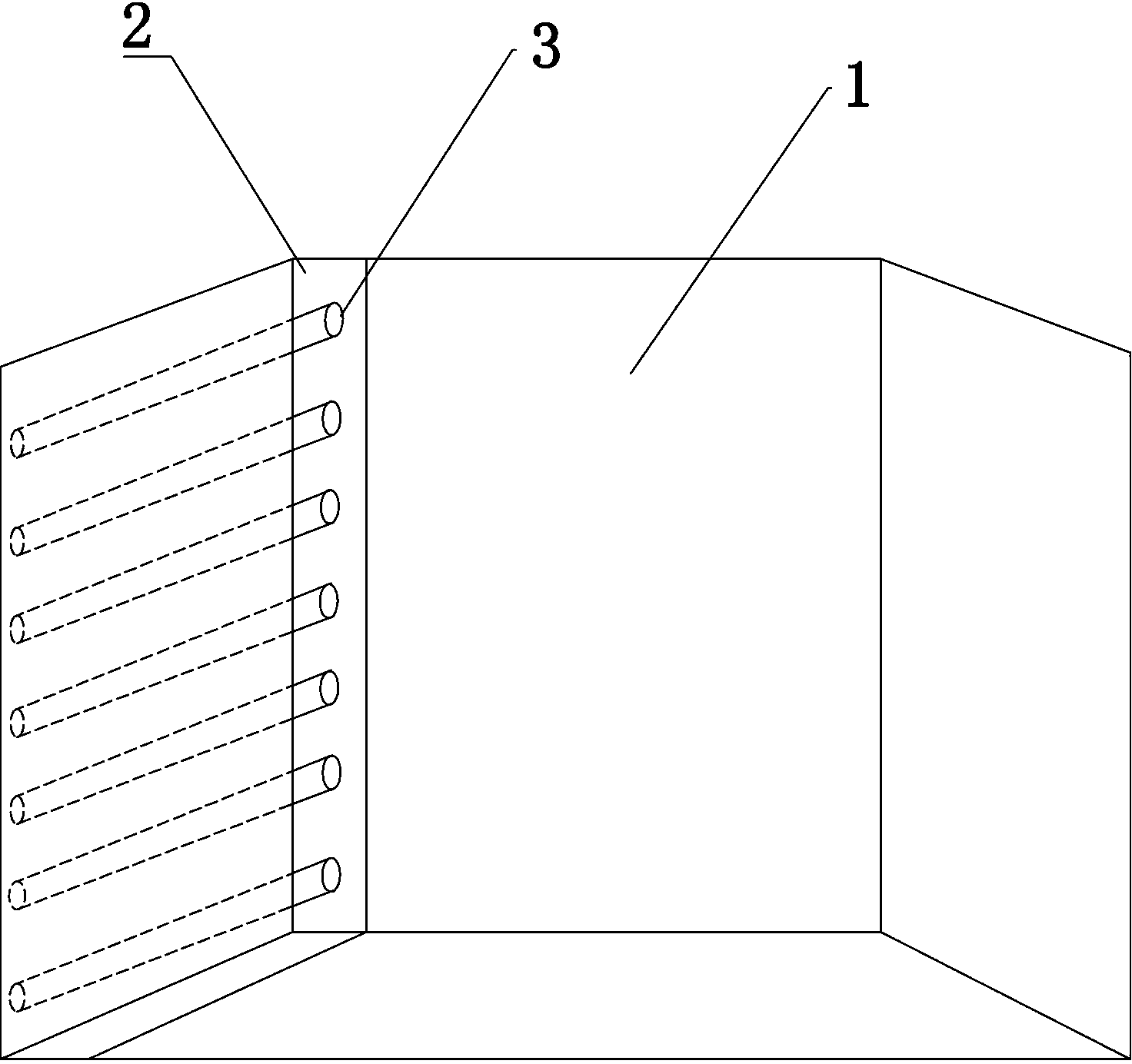

[0040] Such as figure 1 and figure 2 Shown, the dam reinforcement method of the present inventio...

Embodiment 2

[0050] The slurry described in the present invention adopts a two-component high-strength foaming resin, the model of which is SZ2. The two-component high-strength foaming resin includes two components: special resin and hardener. Put the two components into the above-mentioned grouting equipment at the same time. After the two components are mixed, a chemical reaction occurs, and the volume expands rapidly to form a foamy slurry. The exit viscosity of the slurry is 200±65mPa·s. The volume continuously expands in the flow, and the permeability is strong. It is suitable for quickly filling the space and expelling accumulated water under pressure. When the above slurry is injected for 10 minutes, it is completely solidified and reaches its final strength. Its compressive strength is ≥ 1.5MPa, and its Bending strength ≥ 1.3MPa, the slurry does not chemically react with water and is incompatible with water.

[0051] Compared with the existing underwater reinforcement slurry, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com