Controllable mechanism type loading machine with active metamorphic function

It is an active transformation and mechanism technology, which is applied in the direction of mechanically driven excavators/dredgers, etc. It can solve the problems of high cost of hydraulic components, high maintenance cost, and insufficient response, so as to reduce the cost, facilitate remote control, The effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

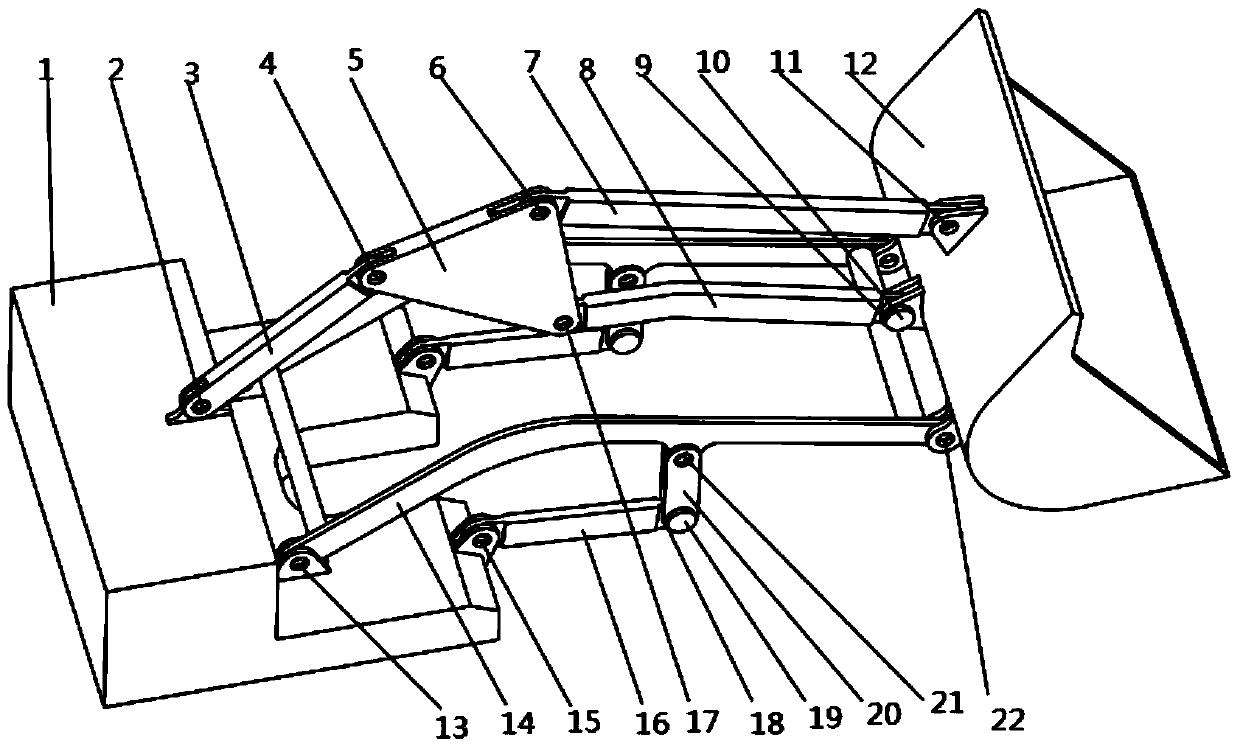

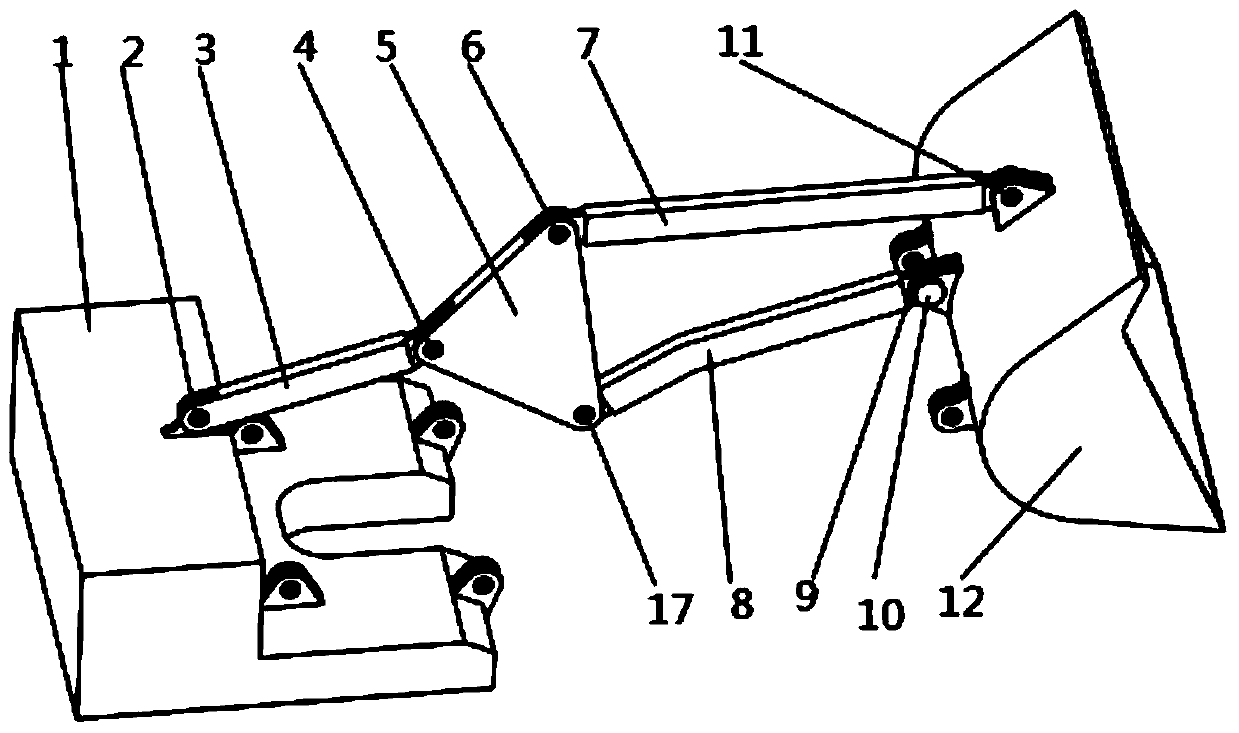

[0021] control figure 1 According to the present invention, the controllable mechanism loader with active cell transformation function includes a frame 1 , a boom lifting mechanism, a bucket turning mechanism, and a first locking device 9 and a second locking device 19 .

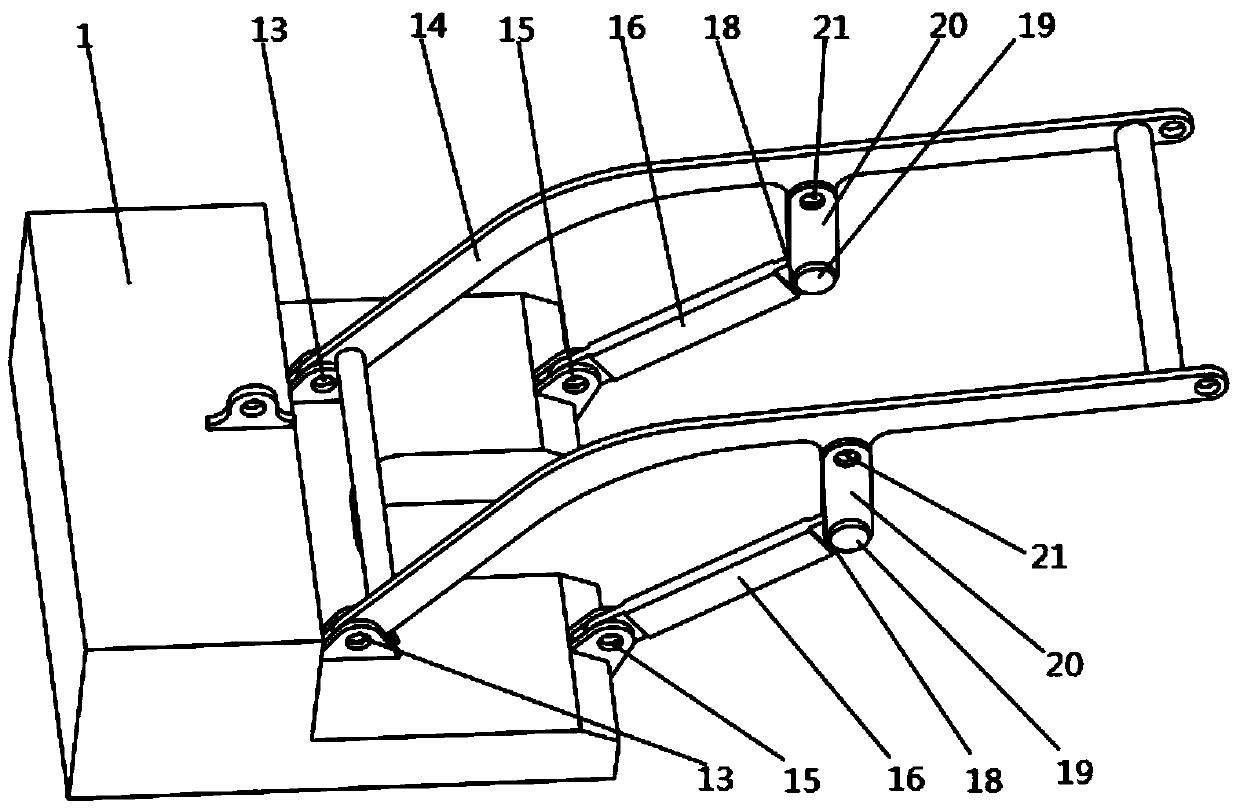

[0022] control figure 1 and figure 2 , the boom lifting mechanism is composed of a boom 14 and a lifting mechanism, the boom 14 is connected to the frame 1 through the seventh rotating pair 13, and the fourth connecting rod 16 of the lifting mechanism passes through the eighth rotating pair 15 Connected to the frame 1, the other end is connected to the fifth connecting rod 20 through the ninth rotating pair 18, and the other end of the fifth connecting rod 20 is connected to the boom 14 through the tenth rotating pair 21.

[0023] control figure 1 and image 3 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com