Large-torque high-speed internal combustion engine

A technology of internal combustion engine and fuel oil, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as power and economic disadvantages, and achieve the effects of eliminating technical obstacles, increasing torque, and reducing base fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

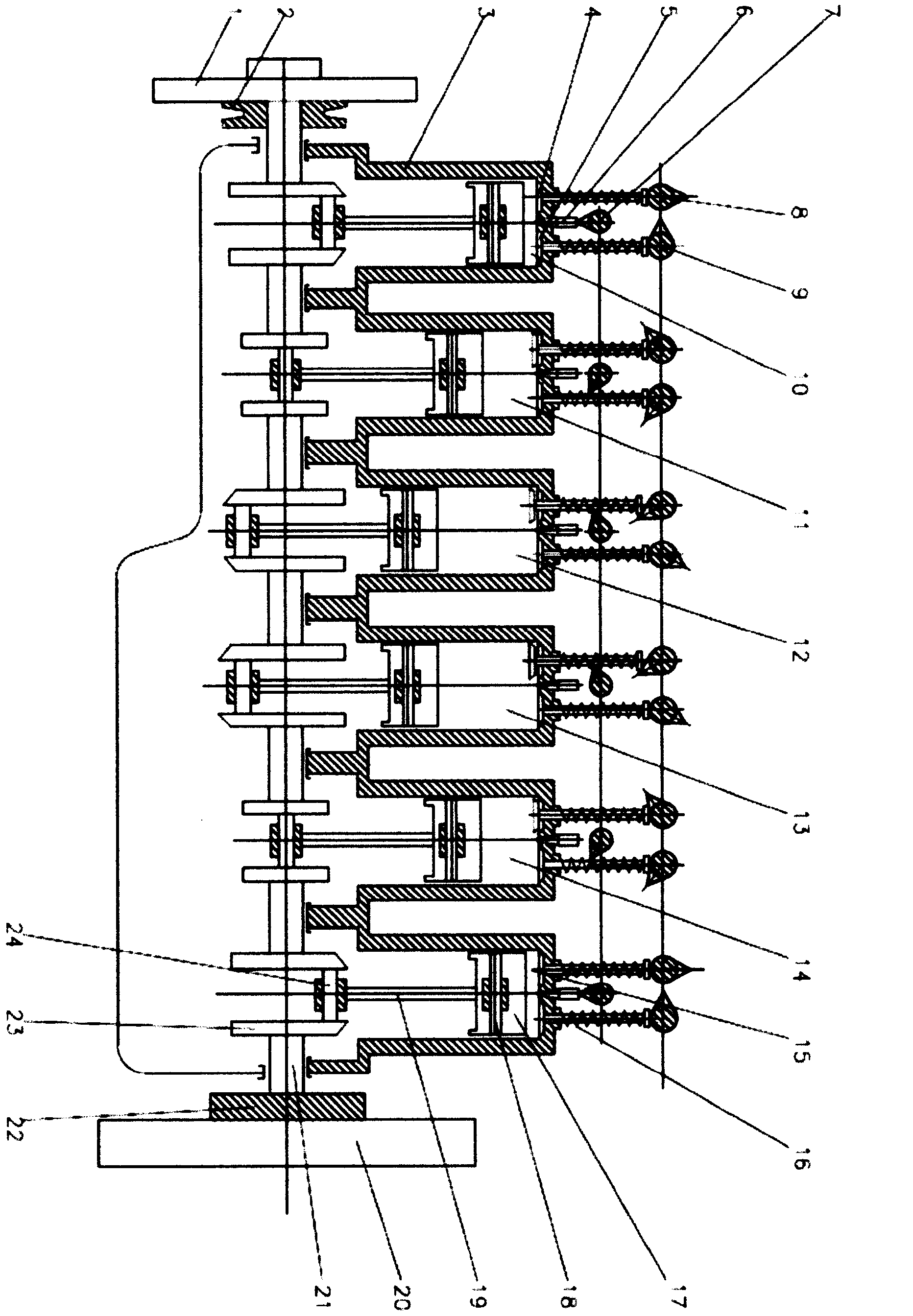

[0026] 1: The opening and closing of the intake and exhaust valves 4; 5 is controlled by the timing cam 8; 9 of the valve train, and the method of controlling the intake and exhaust valves 4; 5 of the two cylinders at the same time is to make the timing cam 8; 9 of the two cylinders The gas distribution phase design is consistent.

[0027] 2: At present, the oil pumps that control the fuel supply are divided into two types: mechanical and electric injection. The picture shows the mechanical oil pump. The mechanical pump uses the oil pump cam 7 to compress the oil cylinder plunger to increase the oil pressure and spray fuel. The phase angle of the oil pump cam 7 rotation is what controls the oil pressure rise to form the fuel injection timing. Therefore, in order to realize the synchronous timing fuel injection of the two cylinders, the phase angles of the oil pump cams 7 of the two cylinders must be consistent.

[0028] The fuel injection timing of the EFI fuel pump is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com