Method for operating electric fuel pump

A fuel pump, voltage technology, applied in the direction of fuel injection pump, fuel injection control, electrical control, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention is shown schematically on the basis of an embodiment in the drawing and is described in detail below with reference to the drawing.

[0023] The drawings are generally and collectively described, like reference numerals referring to like parts.

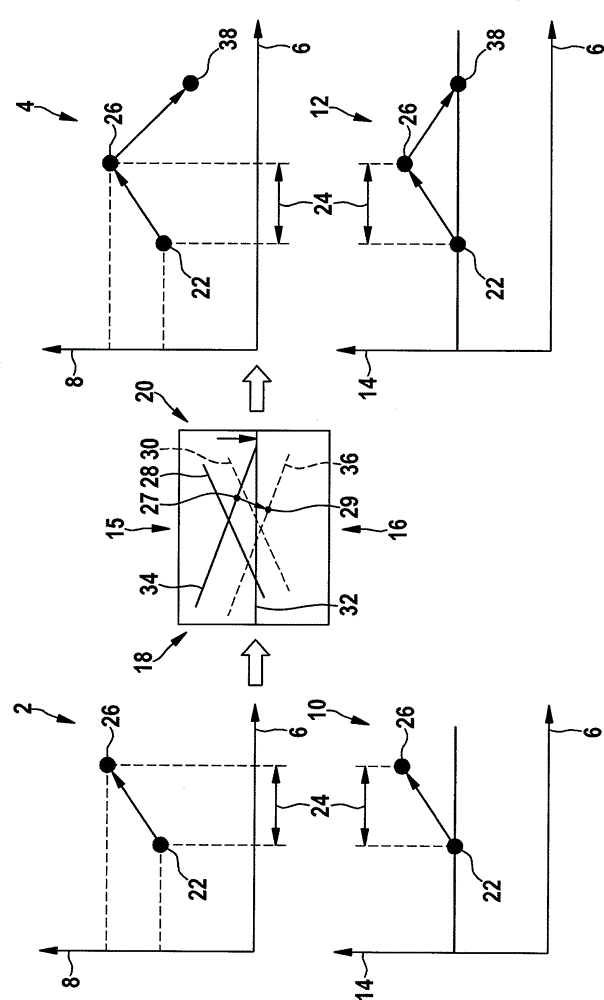

[0024] figure 1 Overall there are five graphs, namely a first pressure-time graph 2 and a second pressure-time graph 4 , in which the time in milliseconds is each recorded along the abscissa 6 and the time in bar is each recorded along the ordinate 8 Fuel pressure in injection equipment. also figure 1 A first current-time diagram 10 and a second current-time diagram 12 are shown, which likewise each have an abscissa 6 along which the time in milliseconds is recorded. Furthermore, the two current-time diagrams 10 , 12 each include an ordinate 14 along which the current flowing through the electric fuel pump of the injection system is recorded in amperes. In the middle between the first pressure-time diagram 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com