Engine fuel system and control method

A fuel system and engine technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve problems such as engine startup failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

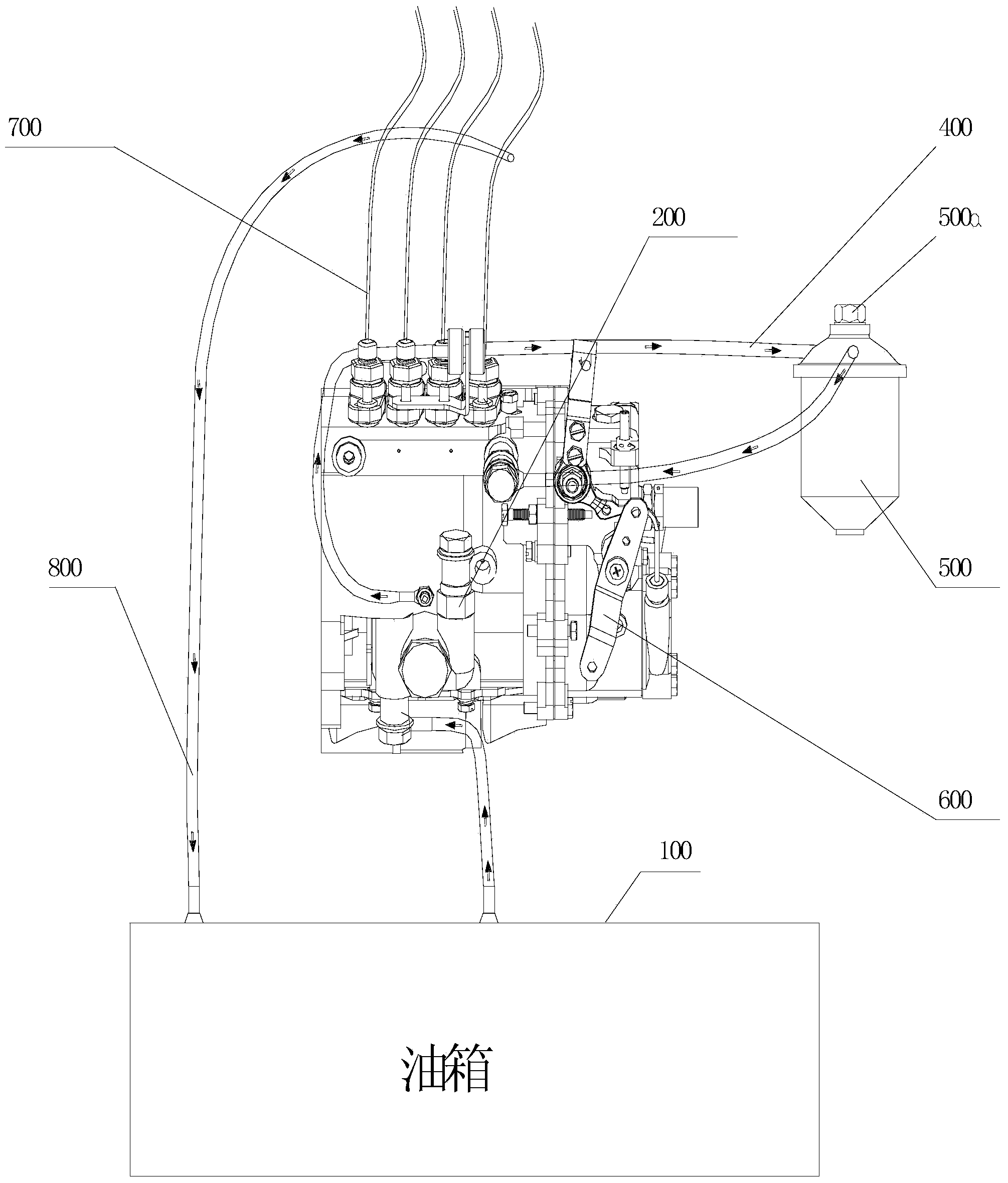

[0052] see image 3 , which is a schematic diagram of Embodiment 1 of the engine fuel system provided by the present invention.

[0053] The engine fuel system provided by the embodiment of the present invention includes: an engine electronic control unit ECU (not shown in the figure), an electronic fuel pump 10, a manual fuel pump 200, a fuel pump 300, an automatic exhaust screw 30 and a diesel filter 500;

[0054]One end of the electronic oil delivery pump 10 is connected to the oil inlet of the manual oil pump 200, and the other end of the electronic oil delivery pump 10 is connected to the oil outlet of the oil delivery pump 300;

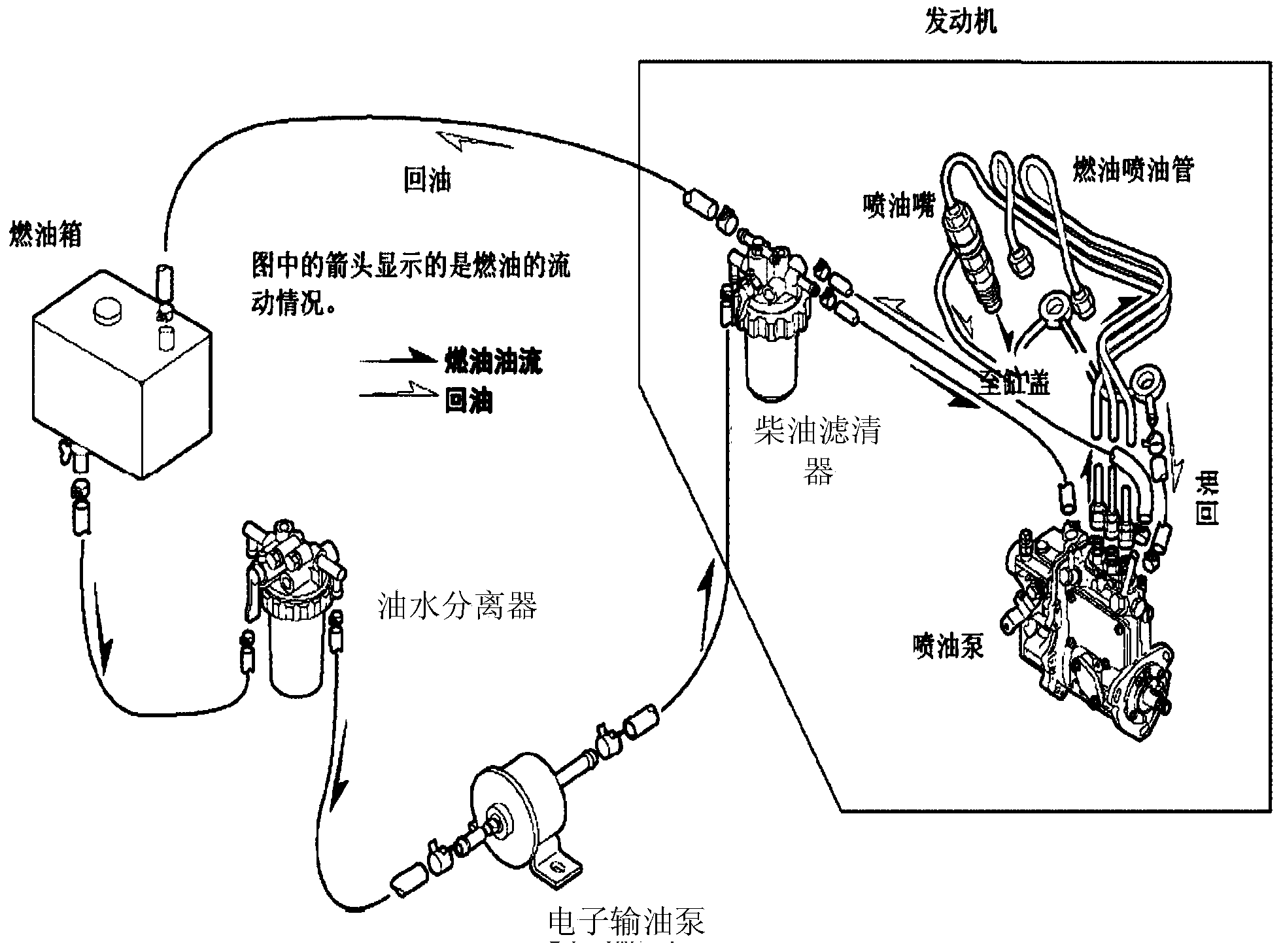

[0055] prior art figure 1 Among them, there is no electronic fuel delivery pump 10, only the manual oil pump 200, and the exhaust in the low-pressure oil circuit is realized by the manual oil pump during the engine and starting stages.

[0056] However, in this embodiment, an electronic fuel delivery pump 10 is added, that is, a pre-fuel suppl...

Embodiment 2

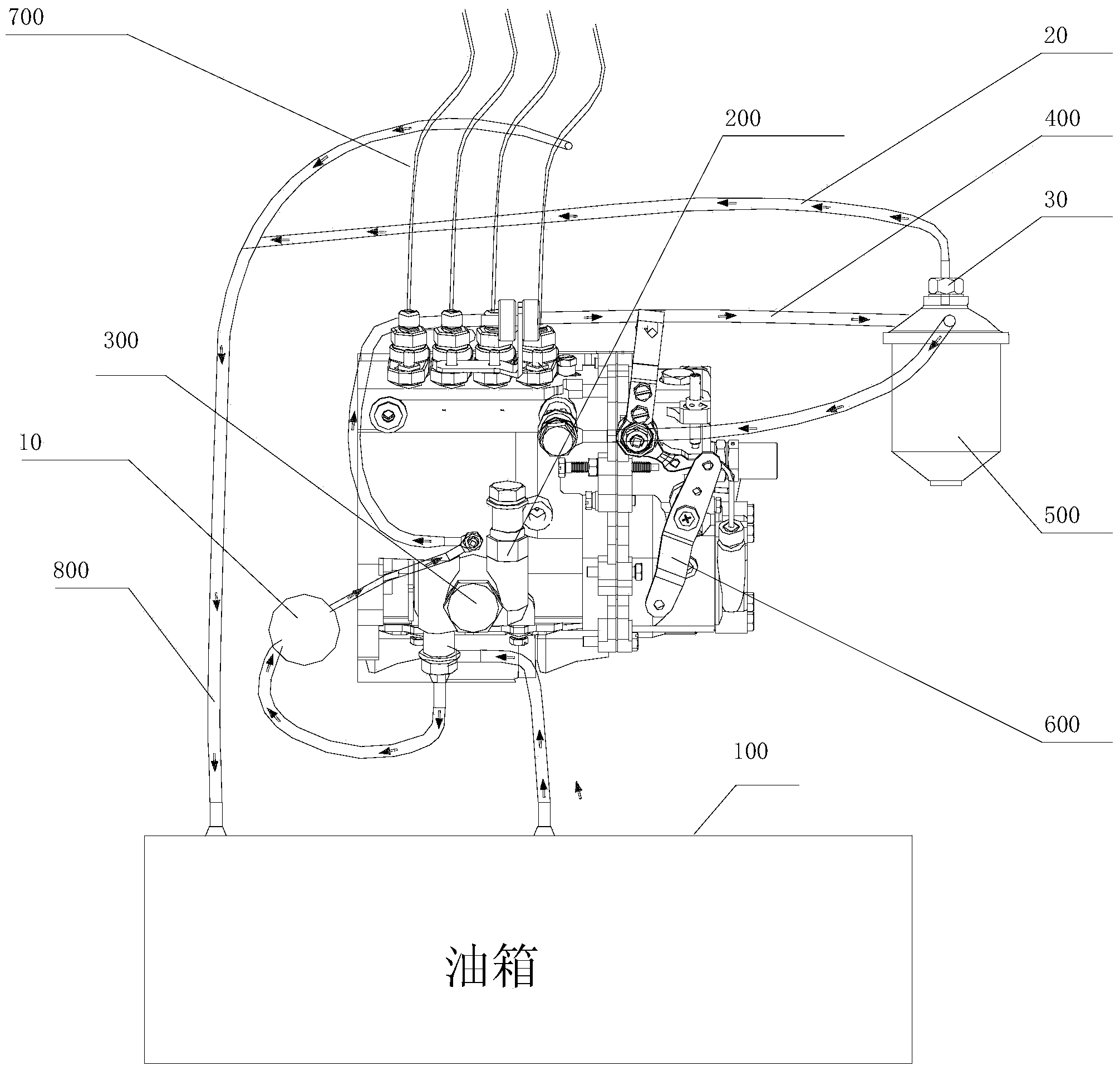

[0067] continue to see image 3 .

[0068] The engine fuel system provided in this embodiment also includes the automatic exhaust pipe 20 and the oil return pipe 800;

[0069] One end of the automatic exhaust pipe 20 is connected to the automatic exhaust screw 30, and the other end of the automatic exhaust pipe 20 is connected to the oil return pipe 800;

[0070] The automatic venting pipe 20 is used to transport the oil discharged from the diesel filter 500 through the automatic venting screw 30 to the oil return pipe 800 .

[0071] Since the gas in the diesel filter 500 is discharged, a certain amount of oil will be sprayed out, so in order to recycle the sprayed oil, it can be recovered. In this implementation, an automatic exhaust pipe 20 is added to automatically discharge the oil. The air pipe 20 is connected with the oil return pipe 800 , and the recovered oil is delivered to the oil return pipe 800 , and the recovered oil is recovered to the oil tank 100 through the ...

Embodiment 3

[0074] It should be noted that, in the second embodiment of the system, the automatic exhaust pipe 20 is connected to the oil return pipe 800 , and the oil ejected from the diesel filter 500 is recovered to the fuel tank 100 through the oil return pipe 800 . In the present embodiment, the automatic exhaust pipe is directly connected to the fuel tank (not shown), and the oil sprayed by the diesel filter is recovered to the fuel tank.

[0075] That is, one end of the automatic exhaust pipe in this embodiment is connected to the automatic exhaust screw, and the other end of the automatic exhaust pipe is connected to the fuel tank;

[0076] The automatic exhaust pipe is used to recover the oil discharged from the diesel filter through the automatic exhaust screw to the fuel tank.

[0077] It should be noted that, in each embodiment of the above system, the engine fuel system may also include a relay;

[0078] The relay is connected in series with the electronic fuel pump;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com