Mileage measuring device and method of in-pipeline detector

An internal detector and pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem of lack of systematic and high-precision detection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

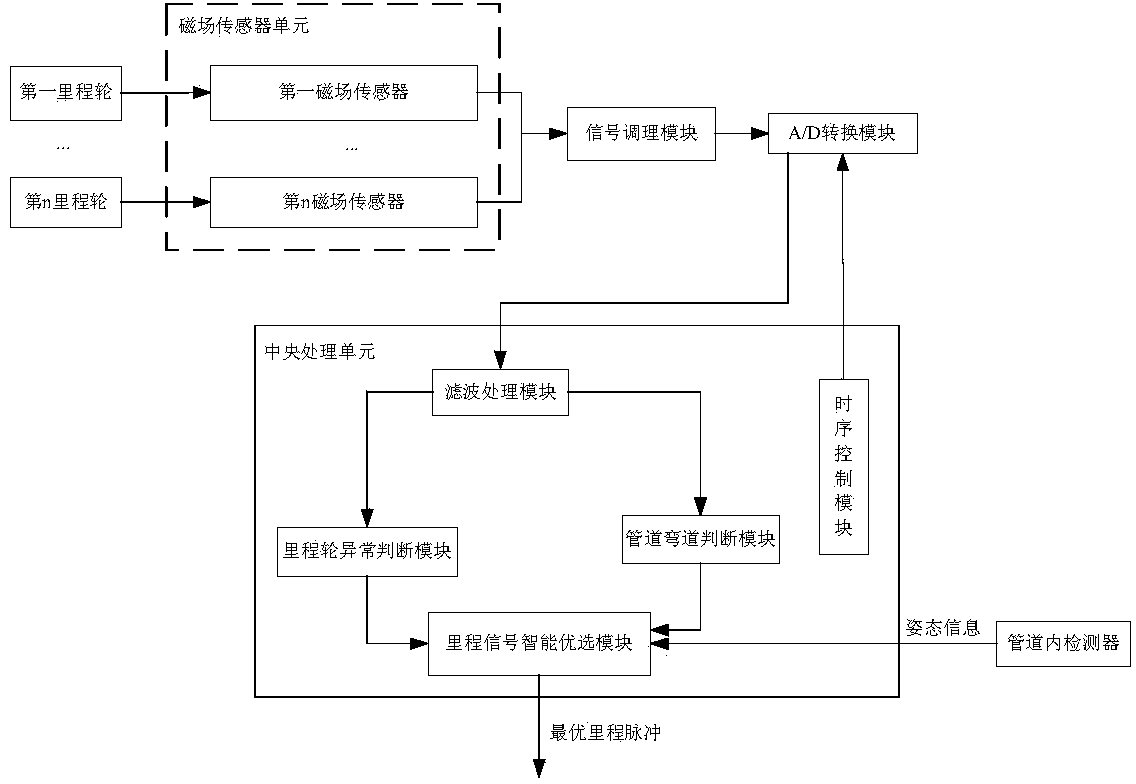

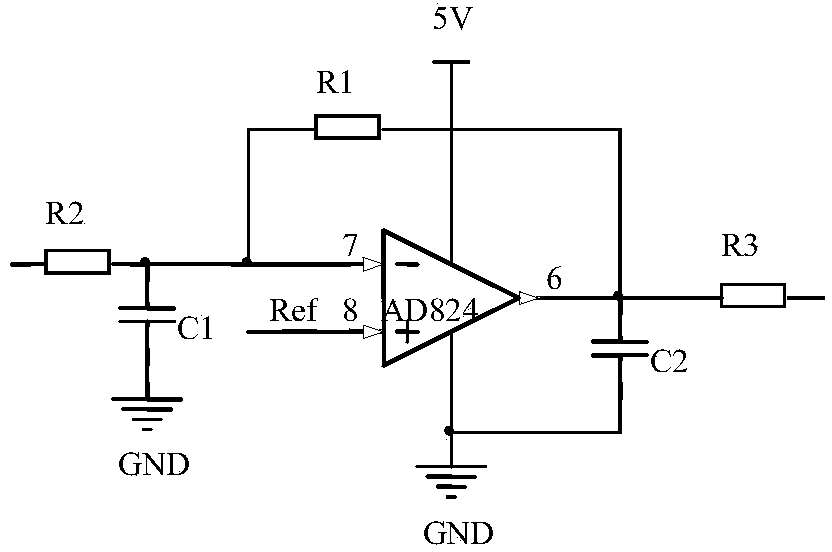

[0054] The in-line detector mileage measurement device in this embodiment is installed on the in-line detector, such as figure 1 As shown, including: magnetic field sensor unit, signal conditioning module, A / D conversion module and central processing unit;

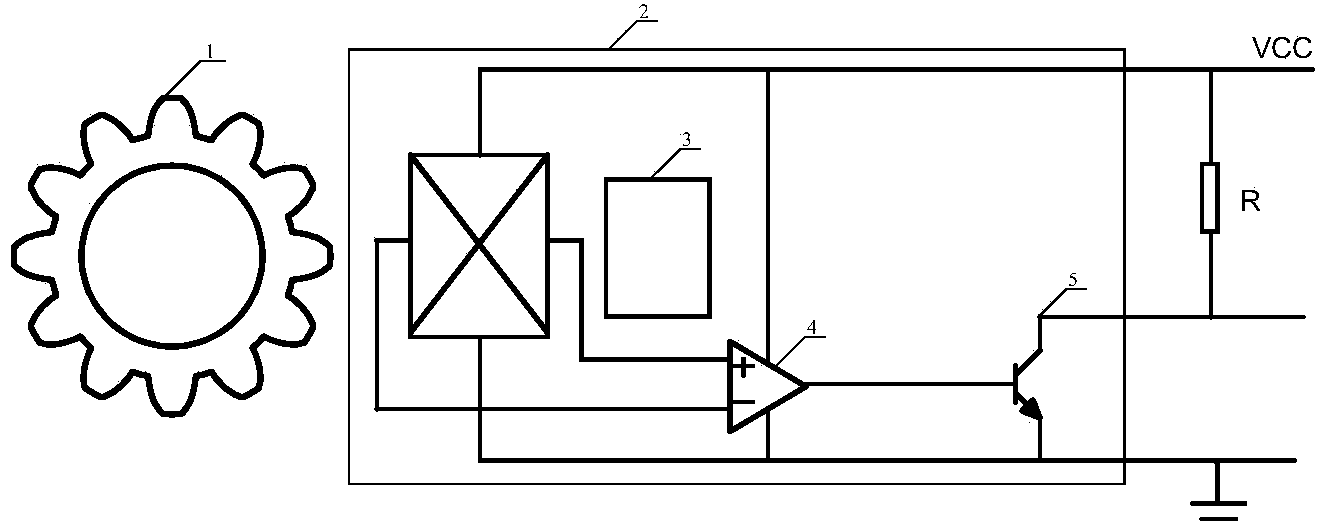

[0055] The magnetic field sensor unit in the present embodiment comprises 3 magnetic field sensors, what described magnetic field sensor all adopts is the Hall sensor of model A44E, each A44E Hall sensor faces the mileage wheel, along with the movement of each mileage wheel, Capture the magnetic field changes of each mileage wheel and output pulse electrical signals to the signal conditioning module;

[0056] The A44E Hall sensor of this embodiment is installed at the end of the detector in the pipe and connected to the mileage wheel through a tension spring. This structure is simpler and more r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com