A method of ultrasonic non-destructive measurement of internal residual stress field of metal sheet

A technology of internal residual stress and metal plates, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems that it is difficult to measure and reflect the residual stress field of plates, and the measurement efficiency is low, so as to achieve fast detection speed, large measurement depth, Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 7050 aluminum alloy cold-rolled plate, length 2000mm, width 1500mm, thickness 5mm. The detection steps are as follows:

[0065] (1) Select the probe

[0066] Two ultrasonic longitudinal wave probes with a wafer diameter of 9 mm and a frequency of 5 MHz were selected.

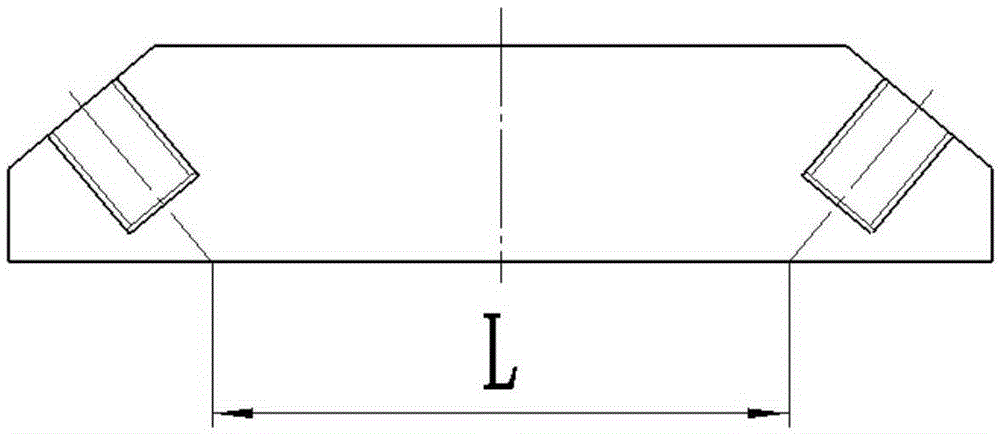

[0067] (2) Wedge processing

[0068] 2.1 Measurement of longitudinal wave sound velocity in wedge material

[0069] The probe is connected to the transmitting / receiving interface of the pulse signal generator with a coaxial cable, and the output interface and the synchronous interface of the pulse signal generator are respectively connected with the input interface and the synchronous interface of the multi-channel digital oscilloscope through the coaxial cable. Process two opposite parallel planes on the wedge material, choose a point A on one of the planes, use a vernier caliper or a micrometer to measure the vertical distance S from this point to the opposite plane 楔块 = 15.0 mm. The ultrasonic pro...

Embodiment 2

[0089] The copper alloy cold-rolled plate of grade H80 is 500mm long, 100mm wide and 3mm thick. The detection steps are as follows:

[0090] (1) Select the probe

[0091] Two ultrasonic longitudinal wave probes with a wafer diameter of 6 mm and a frequency of 10 MHz were selected.

[0092] (2) Wedge processing

[0093] 2.1 Measurement of longitudinal wave sound velocity in wedge material

[0094] The probe is connected to the transmitting / receiving interface of the pulse signal generator with a coaxial cable, and the output interface and the synchronous interface of the pulse signal generator are respectively connected with the input interface and the synchronous interface of the multi-channel digital oscilloscope through the coaxial cable. Process two opposite parallel planes on the wedge material, choose a point A on one of the planes, use a vernier caliper or a micrometer to measure the vertical distance S from this point to the opposite plane 楔块 = 21.5 mm. The ultraso...

Embodiment 3

[0114] 08AL cold-rolled steel plate, 2000mm long, 500mm wide, and 6mm thick. The detection steps are as follows:

[0115] (1) Select the probe

[0116] Two ultrasonic longitudinal wave probes with a wafer diameter of 6 mm and a frequency of 10 MHz were selected.

[0117] (2) Wedge processing

[0118] 2.1 Measurement of longitudinal wave sound velocity in wedge material

[0119] The probe is connected to the transmitting / receiving interface of the pulse signal generator with a coaxial cable, and the output interface and the synchronous interface of the pulse signal generator are respectively connected with the input interface and the synchronous interface of the multi-channel digital oscilloscope through the coaxial cable. Process two opposite parallel planes on the wedge material, choose a point A on one of the planes, use a vernier caliper or a micrometer to measure the vertical distance S from this point to the opposite plane 楔块 = 11.5 mm. The ultrasonic probe is couple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com