Curved surface display module and display device

A curved surface display and module technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as easy breakage, difficult glass substrate, and difficult operation, so as to achieve unbreakable, low product defect rate, and efficient disassembly or assembled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

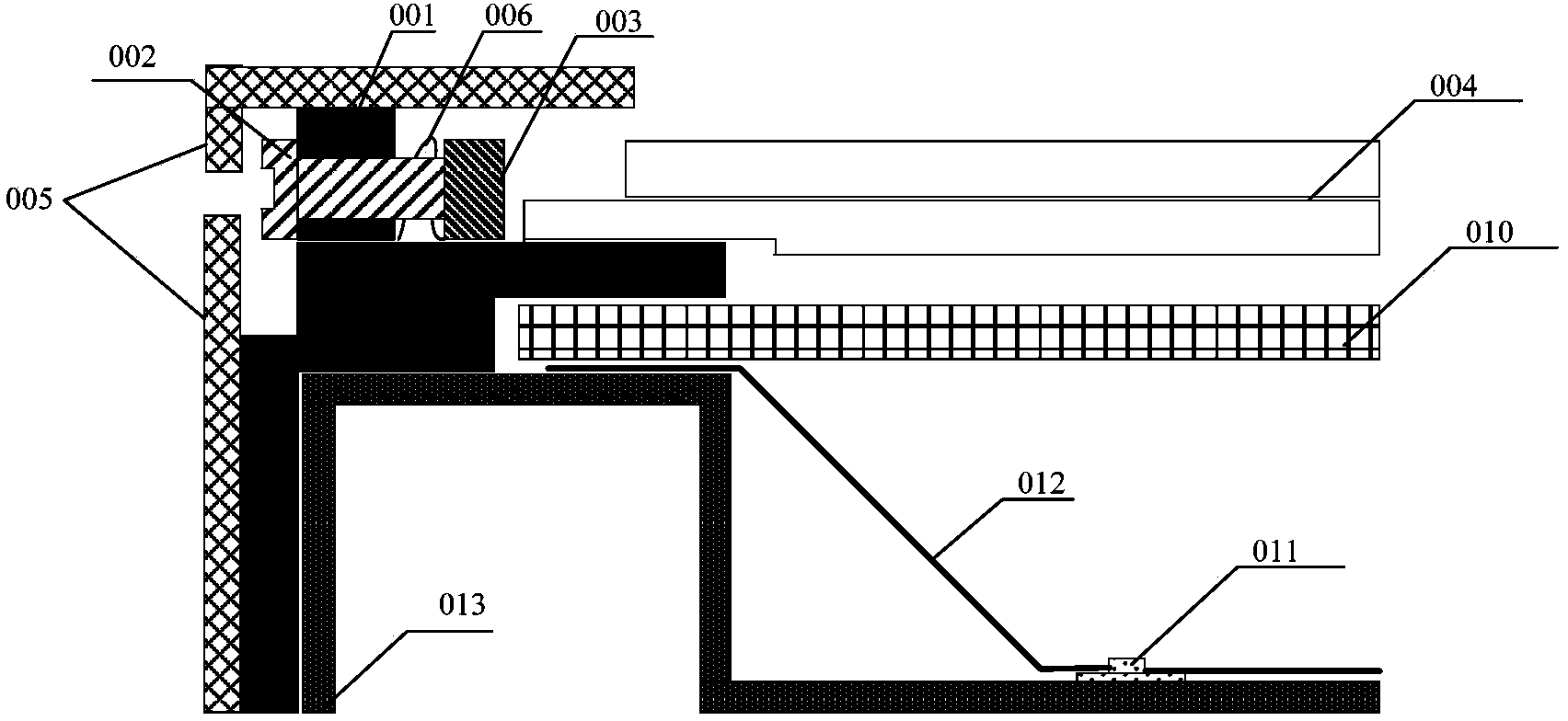

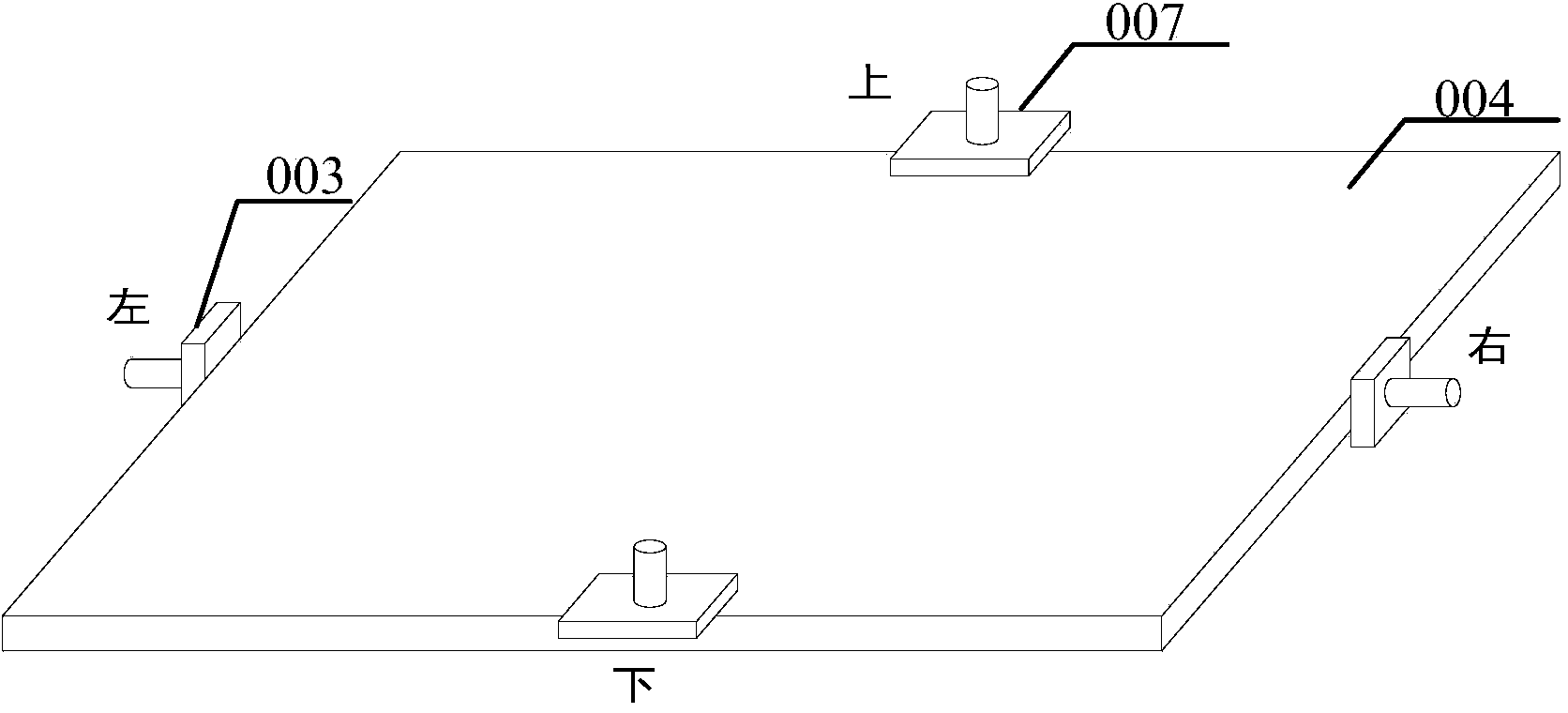

[0026] This embodiment provides a curved display module, the schematic cross-section of the curved display module on the short side of the display panel is shown in figure 1 As shown, it includes a display panel 004 and a rubber frame 001 arranged around the display panel 004, and also includes a stopper 003, which is arranged in the space between at least one short side of the display panel 004 and the rubber frame 001 corresponding to the short side. Inside, by moving the limiting member 003, the limiting member 003 exerts pressure on the short side of the display panel 004, so that the display panel 004 is bent.

[0027] Optionally, the limiting member 003 in this embodiment is disposed on one short side of the display panel 004 or on two short sides of the display panel 004 . To realize a curved display panel, it is necessary to make the display panel bend in a certain arc along the long side, so the stopper is arranged on the short side, and the display panel can be bent ...

Embodiment 2

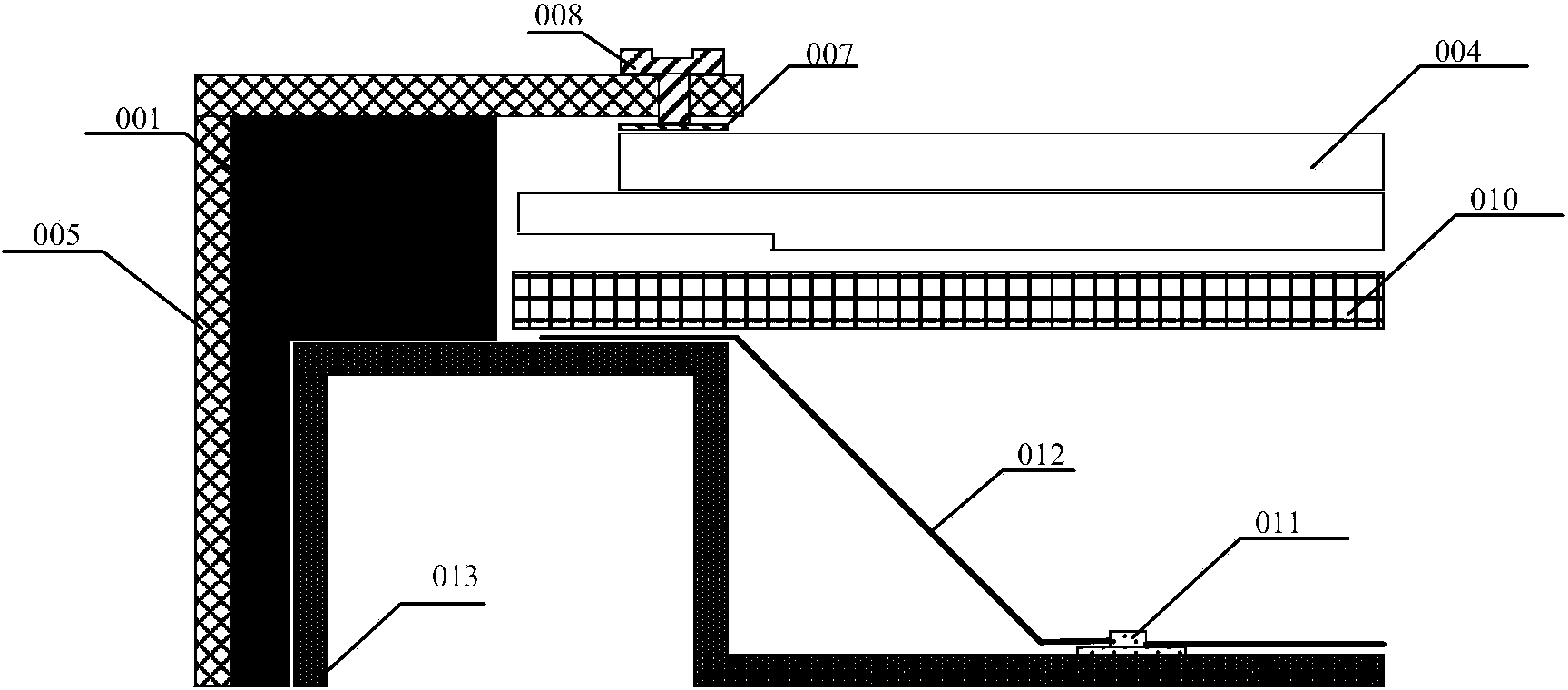

[0037] This embodiment provides a display device, the overall design schematic diagram is as follows image 3 As shown, in addition to the curved display module in Embodiment 1, it also includes a multilayer optical film material 010, a reflector 012, a light source 011, and a back plate 013, which are sequentially arranged under the display panel 004 to form a curved display module. display device.

[0038] It should be noted that, in this embodiment, part of the plastic frame 001 on the left and right sides of the display panel 004 is formed between the display panel 004 and the optical film material 010 to support the display panel 004, see figure 2 . But the plastic frame 001 on the upper side and the lower side of the display panel 004 is only arranged at the end face position of the display panel 004 and the optical film material 010, and is not formed at the part between the display panel 004 and the optical film material 010, that is, this position ( The plastic frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com