Ball and socket breakaway connector

A technology of connectors and ball joints, which is applied in the field of separation connectors, and can solve problems such as damage to the main hose of the fuel dispenser by the whip hose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

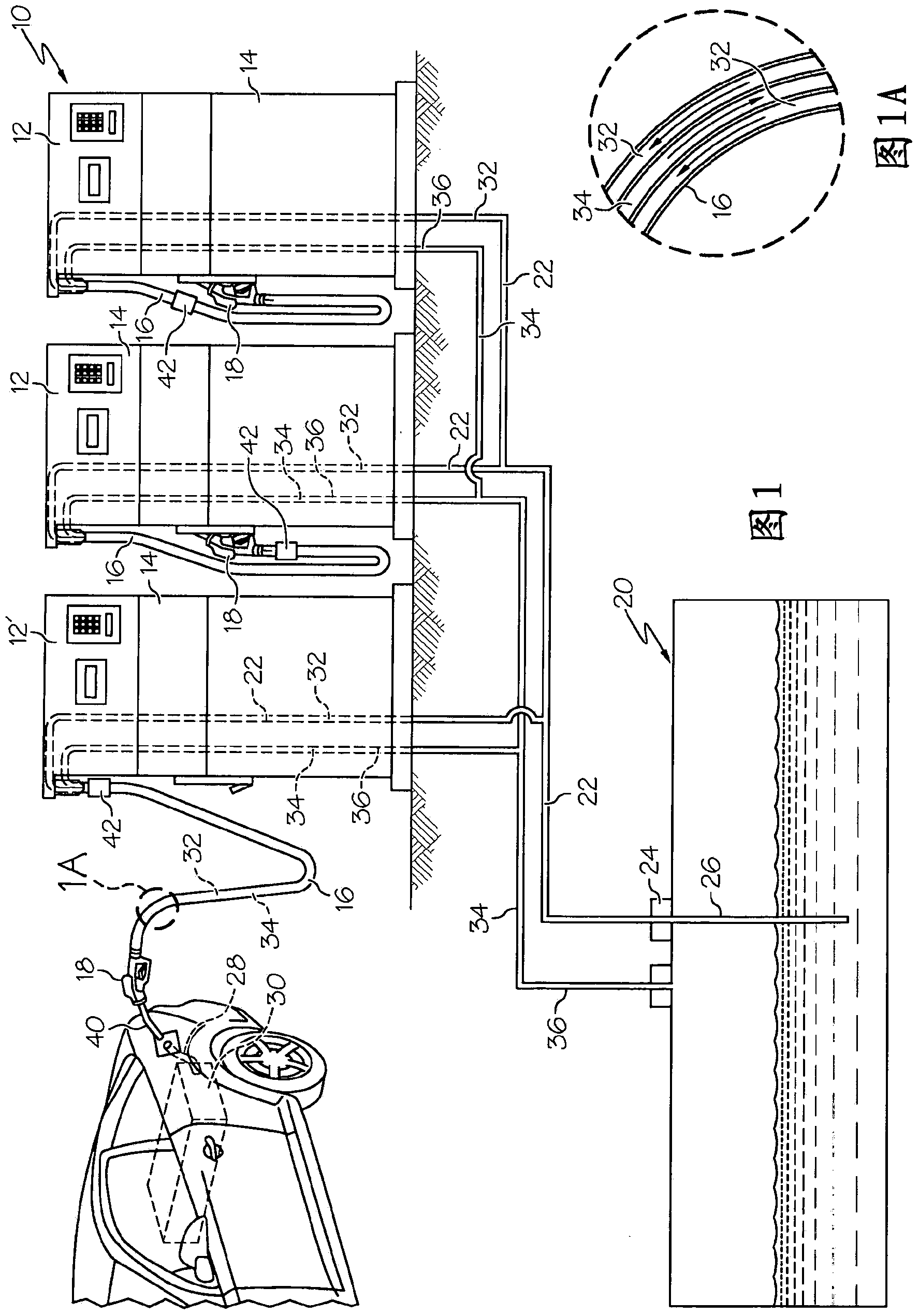

[0018] figure 1 It is a schematic diagram of a refueling system 10 including a plurality of refueling machines 12. Each tanker 12 includes a tanker body 14, a hose 16 coupled to the tanker body 14, and a nozzle 18 located at the distal end of the hose 16. Each hose 16 should generally be flexible and flexible to allow positioning of the hose 16 and nozzle 18 in a convenient refueling position according to the needs of the user / operator.

[0019] Each fuel dispenser 12 is in fluid communication with the fuel / fluid storage tank 20 through a liquid or fluid pipeline or path 22 that extends from each fuel dispenser 12 to the storage tank 20. The storage tank 20 includes a fuel pump 24 or is fluidly coupled to the fuel pump 24 which is configured to draw fluid / fuel from the storage tank 20 through a pipe 26. During the refueling period, such as figure 1 As shown in the fuel dispenser 12' in use, the nozzle 18 is inserted into the fuel filler pipe 28 of the vehicle fuel tank 30. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com