Electromagnetic inductive heating device

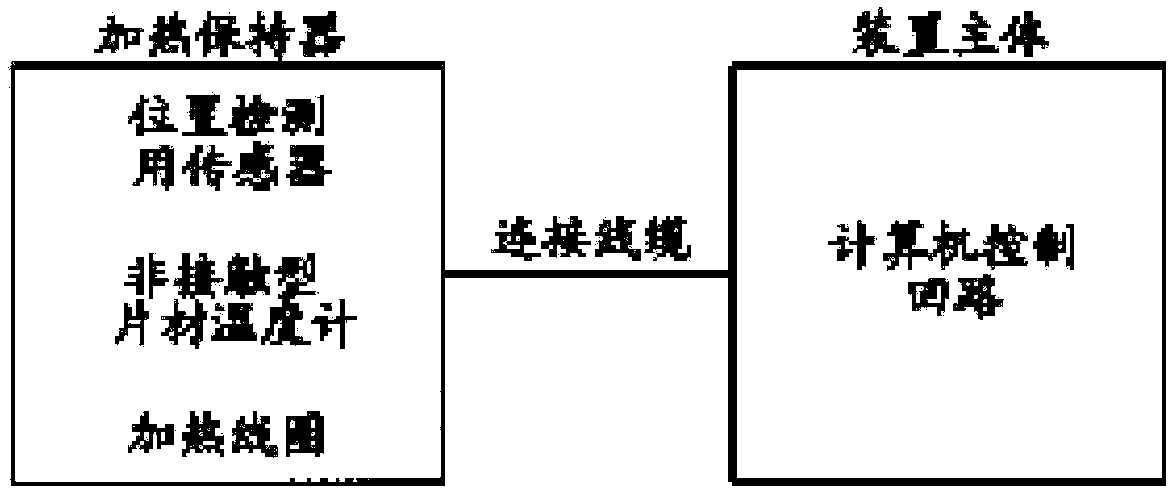

A technology of electromagnetic induction heating and heating time, applied in induction heating devices, induction heating, induction heating control and other directions, can solve the problems of large temperature changes, temperature changes day and night, difficult to obtain the joint state of fixed parts and waterproof sheets, etc. Efficiency and easy temperature measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, an example of embodiment of the electromagnetic induction heating device of the present invention will be described with reference to the drawings.

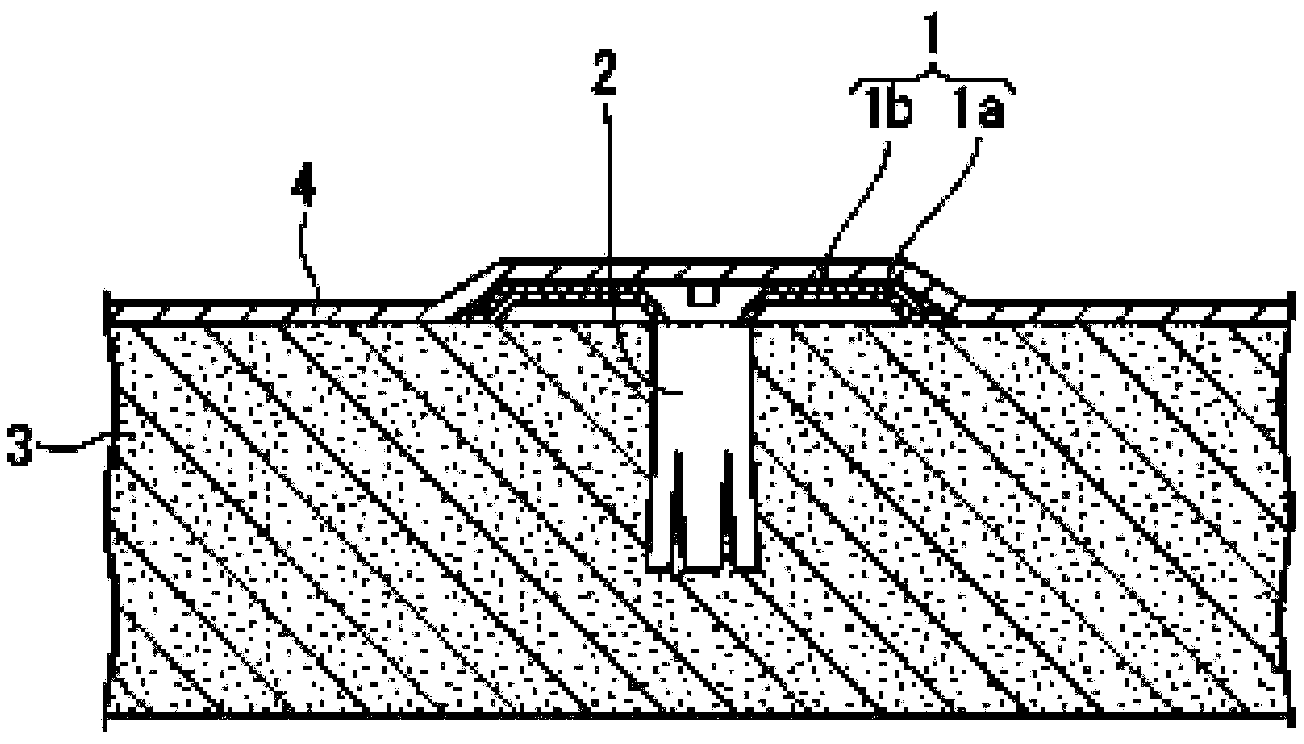

[0044] In one embodiment of the present invention, when the sheet is laid on the roof slab of a building for the purpose of waterproofing, etc., a fixing member having a conductive matrix and a thermoplastic resin layer is provided at a predetermined position on the roof slab, covering the entire surface. A sheet covering the fixing member is laid on the bottom surface, and the conductive substrate is heated from above the sheet by electromagnetic induction heating, and the thermoplastic resin layer is melted by the heat, and the sheet is bonded to the fixing member.

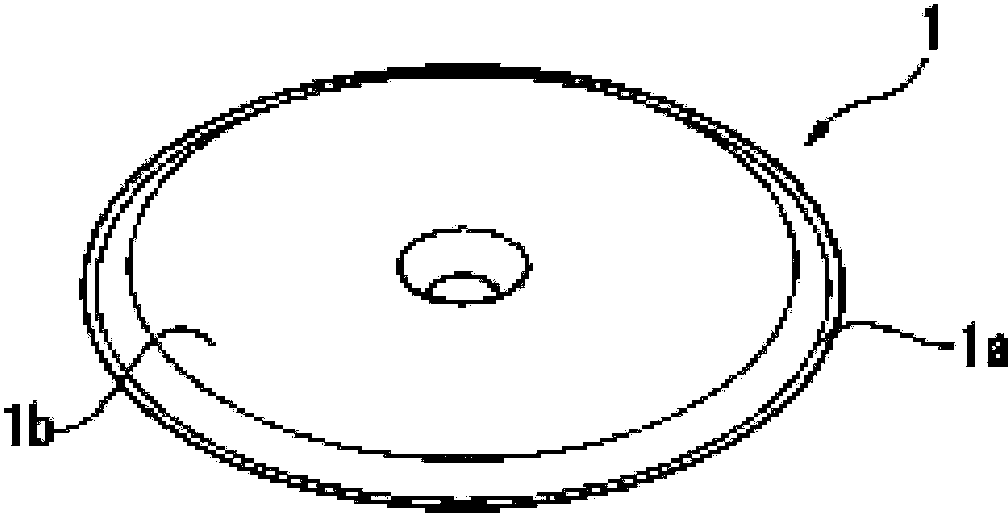

[0045] figure 1 is a fixing member showing one embodiment of the present invention.

[0046] In this example, the fixing member 1 has a two-layer structure in which a conductive substrate 1a which is a disk-shaped thin plate is coated on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com