Safety helmet shell capable of deforming for buffering

A technology for safety helmets and hat shells, applied to hats, hat products, clothing, etc., to achieve the effect of eliminating discomfort and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

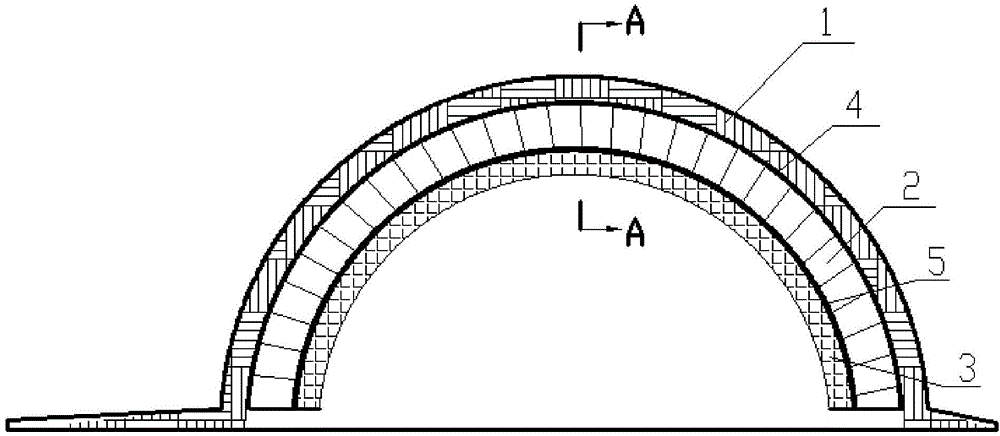

[0021] The deformable cushioning safety helmet shell according to the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

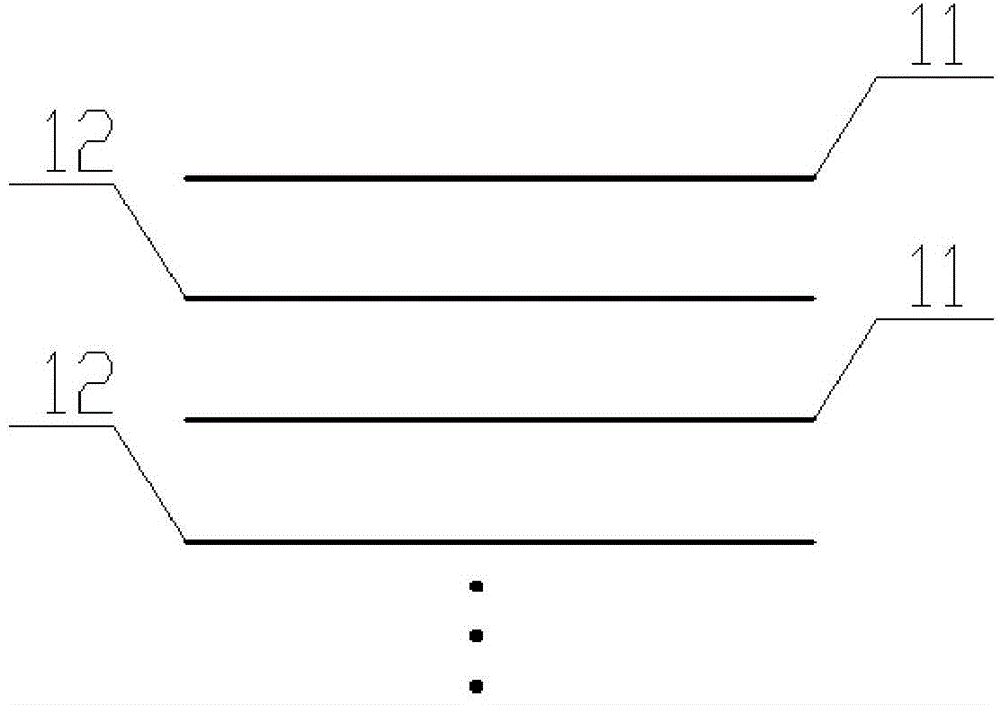

[0022] The present invention changes the hard shell of the conventional safety helmet, that is, the cap shell, into a flexible carbon fiber material, and replaces the belt-shaped cap lining with a honeycomb structure, which improves the uneven stress state of the safety helmet under the action of external impact load, and avoids the conventional The hidden danger that the hard shell of the helmet is broken and the head is directly subjected to the impact load. The deformable energy-absorbing safety helmet with the honeycomb structure as the buffer layer not only ensures that the local force of the cap shell is not damaged when the local impact load is large, but also eliminates the hidden danger of the residual impact load directly acting on the head. The deformable buffer safety helm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com