An electrospray microfluidic chip, manufacturing method and mask plate equipment

A technology of microfluidic chip and manufacturing method, which is applied in the direction of microlithography exposure equipment, chemical instruments and methods, photoplate making process of pattern surface, etc., can solve the problems such as poor electrospray effect of polymer microfluidic chip, and achieve Improvement of stability and ionization effect, improvement of spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

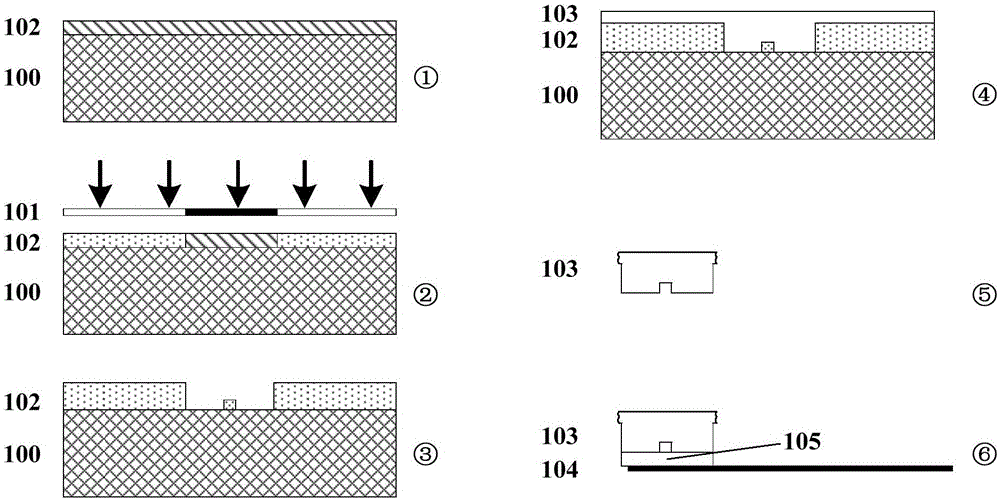

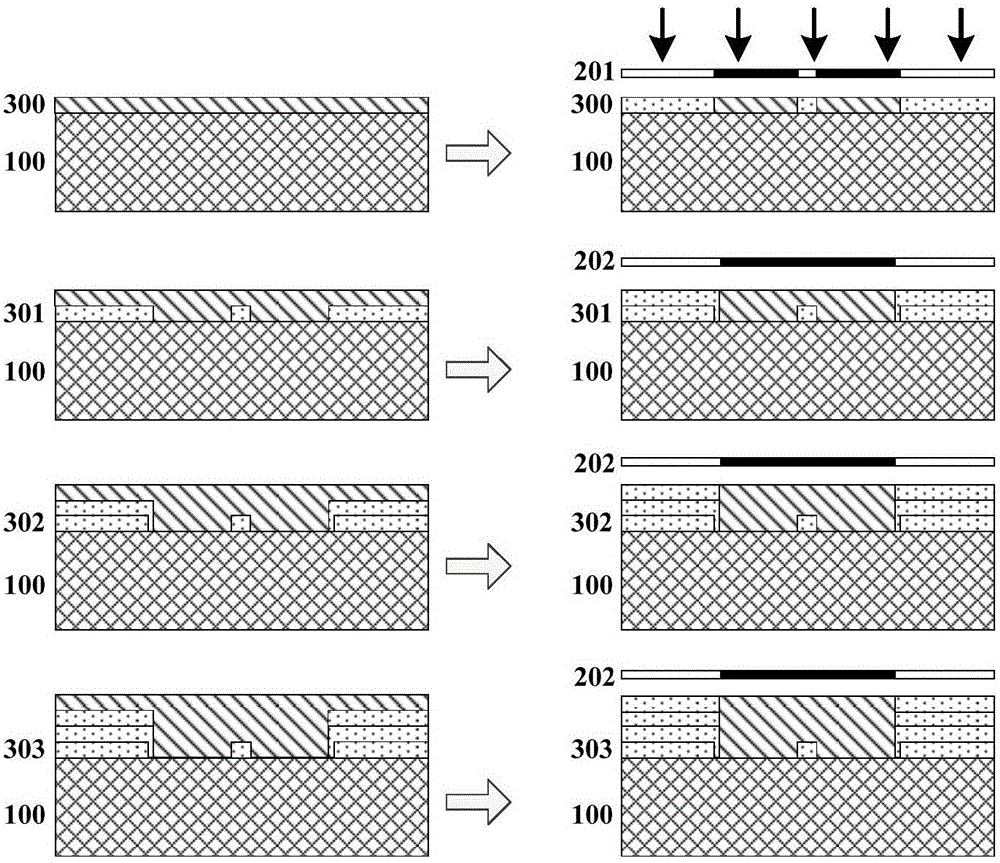

[0039] refer to figure 1 , according to the preparation method of the embodiment of the present invention, the chip mold can be made by using a soft photolithography process. The basic process includes: preparing a mask, throwing the photoresist, exposing, developing and forming a mold, pouring the mixed polymer into the mold, curing and peeling , dicing and bonding. figure 1 Among them, ① represents the step of removing glue; ② represents the step of exposure; ③ represents the step of developing; ④ represents the step of polymer injection; ⑤ represents the step of curing and cutting; ⑥ represents the step of bonding. Wherein, steps ①, ②, and ③ can be carried out multiple times as required (to be further described in detail below).

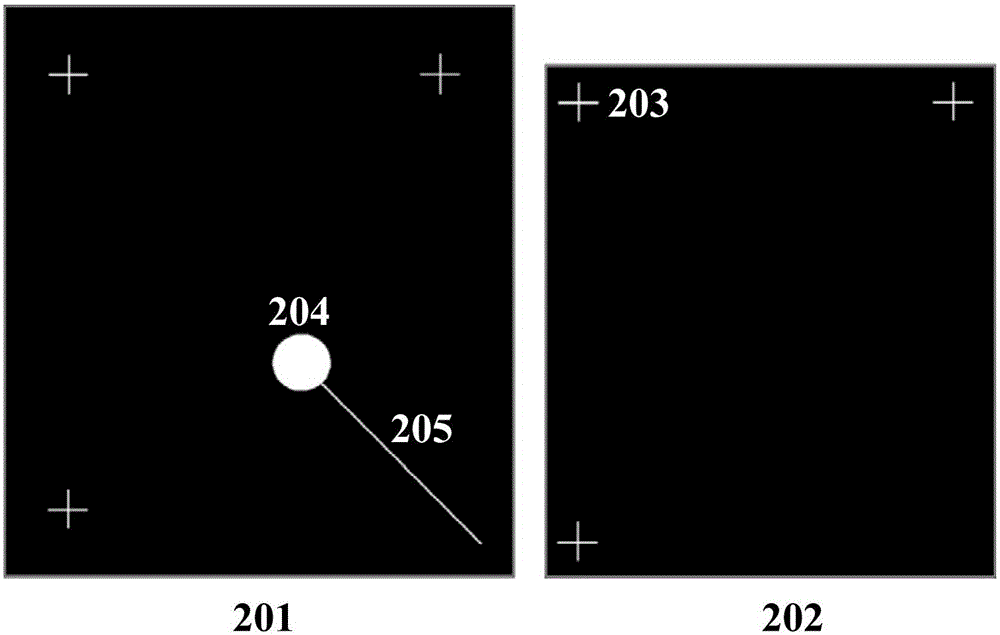

[0040] Such as figure 2 As shown, two rectangular film masks 201 and 202 can be used, and each mask has a light-transmitting area and an opaque area.

[0041] The two reticles 201 and 202 both have three light-transmitting regions marked with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com