Pre-cleaning separator for PET (Polyethylene Terephthalate) bottle

A pre-cleaning and separator technology, which is applied in the field of separators, can solve problems such as impurity cannot be separated, crushing knife damage of the crusher, and service life of the crusher is reduced, so as to save water, prolong the service life and improve the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples.

[0018] The high temperature mentioned in this embodiment does not refer to the high temperature exceeding a specific temperature value. The high temperature raised by the present invention refers to the temperature range that can make PVC or PC bottles change color, which is called high temperature.

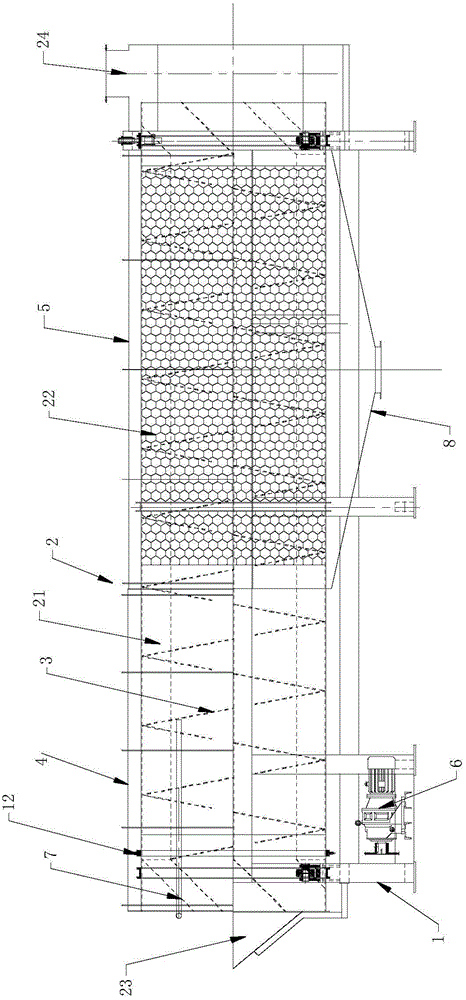

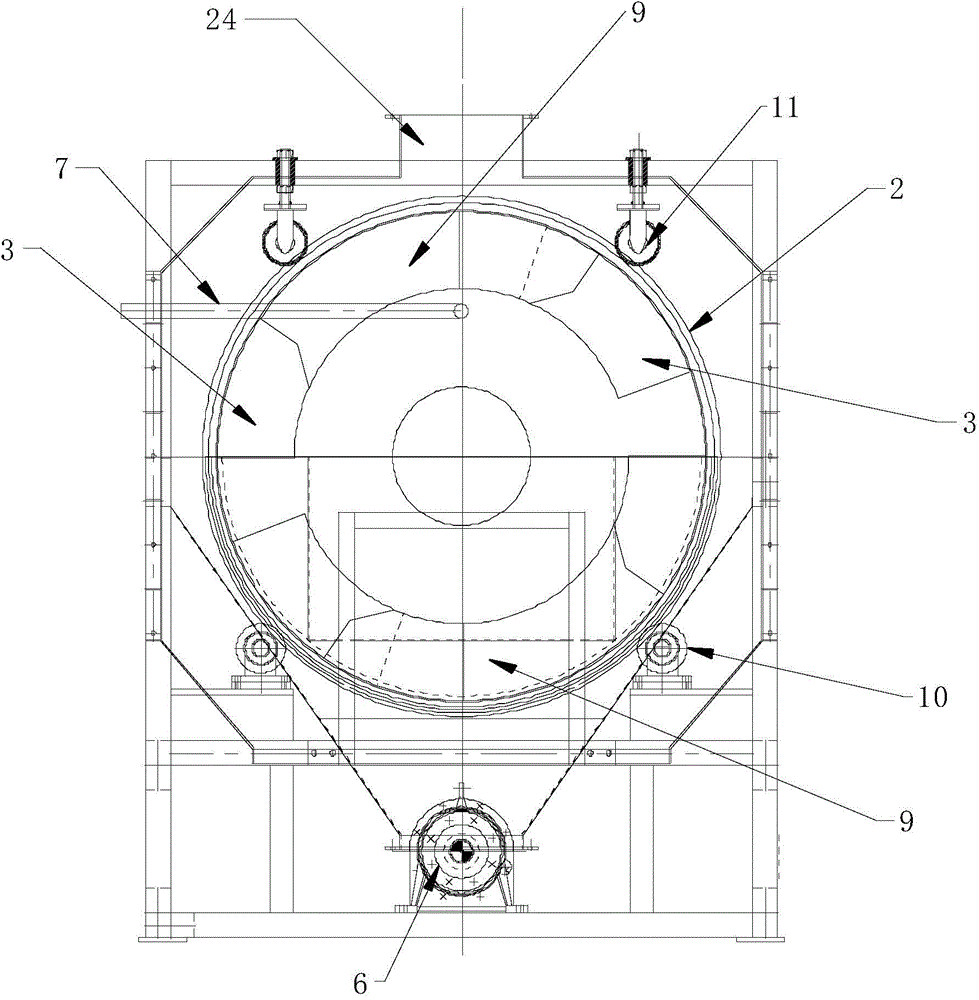

[0019] Such as figure 1 , 2 As shown, a PET bottle pre-cleaning separator includes a frame 1, a drum 2, a drum driving device 6, and the drum 2 is rotatably mounted on the frame 1, and the drum driving device 6 is mounted on the frame 1 and The transmission connection between the drum 2 can drive the drum 2 to rotate, and the frame 1 includes at least three fixed supports, which are evenly distributed along the length direction of the drum 2, and each fixed support is installed below the drum 2 At least two support rollers 10, at least two limit rollers 11 are installed above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com