Production technology for cigarette package box

A production process and packaging box technology, which is applied to the production process field of cigarette packaging boxes, can solve the problems of unenvironmental protection of materials, waste of materials, low production efficiency, etc., so as to reduce edge trimming and polishing production processes, reduce production costs, and improve production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

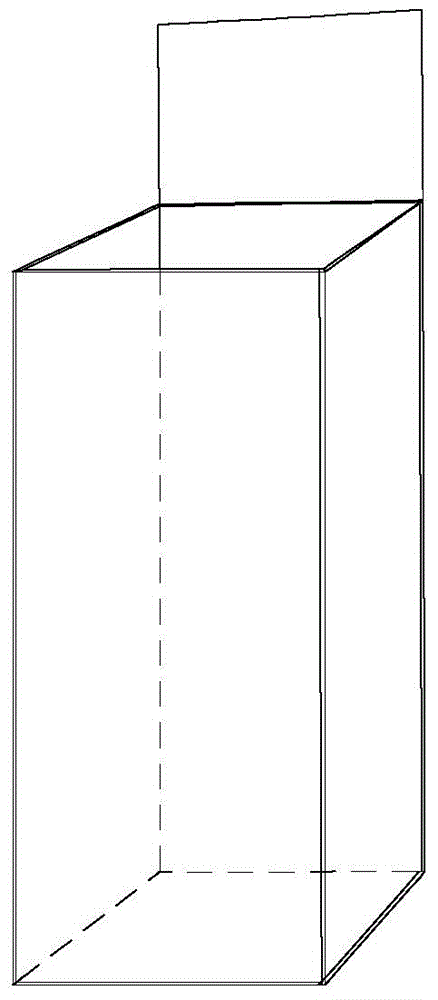

[0045] see Figure 6 As shown, the embodiment of the present invention provides a kind of production technology of cigarette packing box, comprises the following steps:

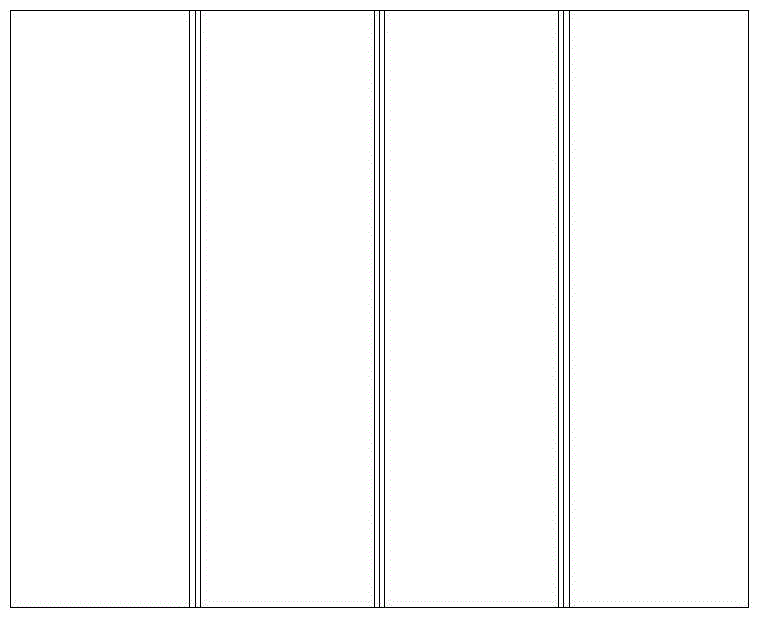

[0046] Step S1. blanking, select 1.0mm white cardboard, use a paper cutter to cut into two first white cardboards and a second white cardboard; the two first white cardboards are rectangular, and the length is 310mm, the width 190mm; the second white cardboard is rectangular, and the length is 738mm, and the width is 38mm.

[0047] Step S2. Die cutting, see Figure 7 and Figure 8 As shown, use a die-cutting machine to die-cut the two first white cardboards into the first foldable shape and the second foldable shape respectively, and process them half-cut, and set a half-cut line at a distance of 15mm from the four sides of the first foldable shape , open a half-cut line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com