Unhairing machine for spinning

A wool machine and textile technology, applied in the field of dehairing machines for textiles, can solve the problems of high cost of dehairing and polishing enzymes, uneven dyeing of fabrics, inability to use repeatedly, etc., to achieve the effect of enhanced hair removal, easy management, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

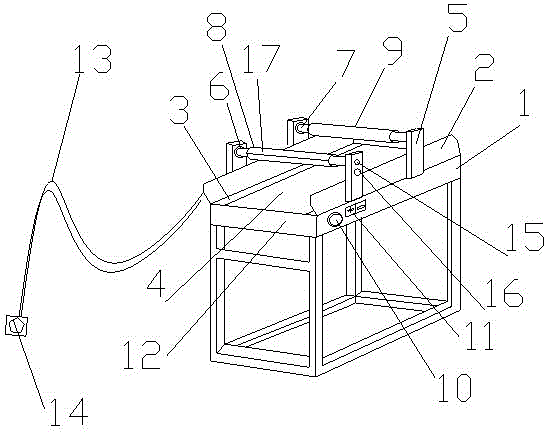

[0016] like figure 1 Shown is an embodiment of the dehairing machine for weaving of the present invention, the dehairing machine for weaving includes a workbench 1, two supports 2 are arranged symmetrically at both ends of the workbench 1, and two supports 2 are arranged between them. There is a transmission shaft 3, a conveyor belt 4 is arranged on the transmission shaft 3, two pairs of brackets 5 are symmetrically arranged on the two supports 2, and a first horizontal axis 6 and a second horizontal axis 7 are arranged in parallel between the two pairs of brackets 5, and The second horizontal axis 7 is arranged behind the first horizontal axis 6, the first horizontal axis 6 is provided with a hair remover 8, the second horizontal axis 7 is provided with an electrostatic cylinder 9, and the side of the workbench 1 is provided with a switch button 10, An adjustment button 11 is arranged next to the switch button 10, a controller 12 is arranged in the workbench 1, and the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com