Flange power-generating water-spraying thruster

A water-jet propulsion and rim technology, which is applied in the direction of propulsion components, ship propulsion, hydropower generation, etc., can solve the problems of weakening ship thrust, increasing additional resistance, difficult to manufacture an ideal Grim impeller, etc., to improve propulsion performance, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

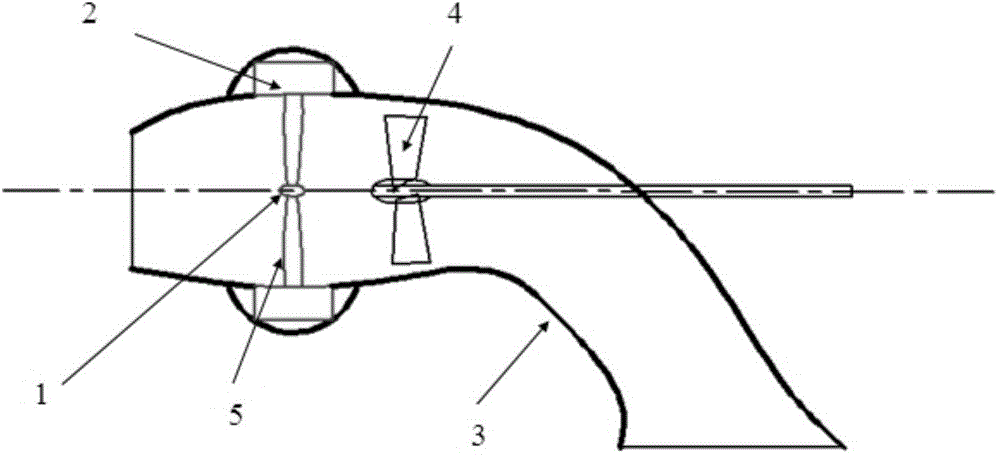

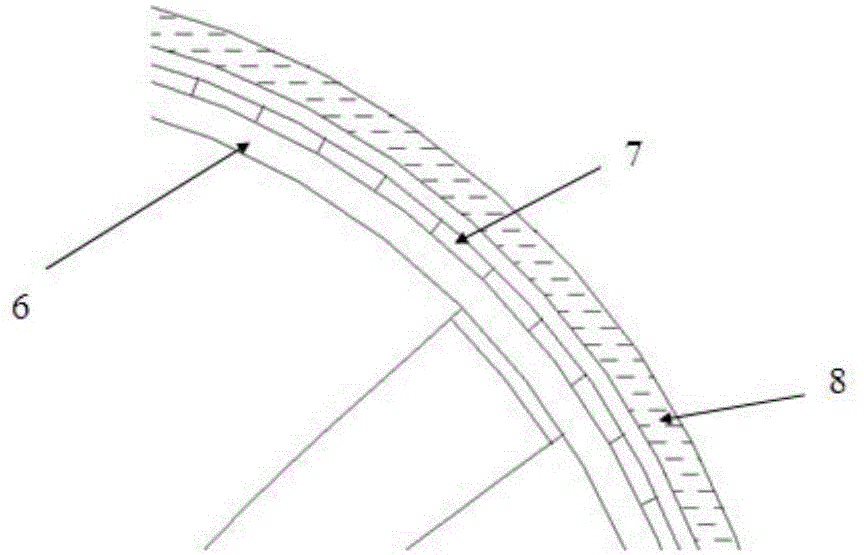

[0020] combine Figure 1-5 , the present invention adopts rim generator or ring generator to replace the rear stator of conventional water jet propeller. The rim generator is fixedly installed with the waterjet shell, and the blades of the rim generator are driven by the tail swirl generated by the rotation of the front water pump, thereby driving the generator to generate electricity, which can provide additional electric energy for the normal operation of the ship. The distance between the front water pump and the impeller of the generator is about 0.15 times the diameter of the front propeller.

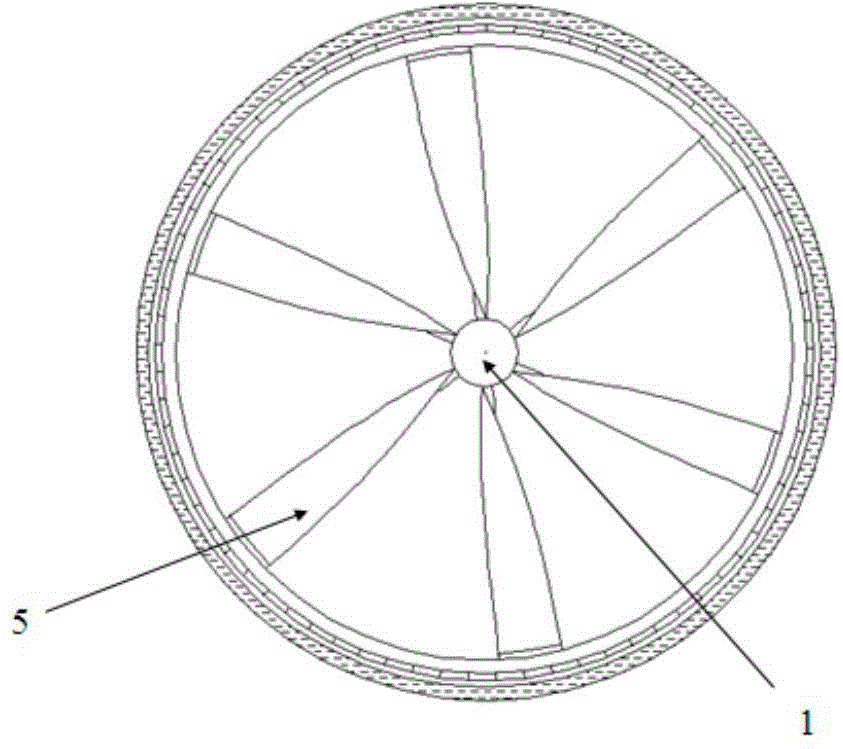

[0021] figure 1 The general arrangement of the system equipment is given. The device is composed of impeller center hub 1, rim generator or ring generator 2, inlet pipe 3, water pump 4 and impeller 5 and so on. The blades of the impeller 5 are evenly distributed al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com