Floor heating panel and floor heating panel assembly

A geothermal floor and floor technology, which is applied to central heating components, household heating, heating methods, etc., can solve the problems of unsatisfactory heating effect and high energy consumption, and achieve the effect of improving heating effect, saving construction costs, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

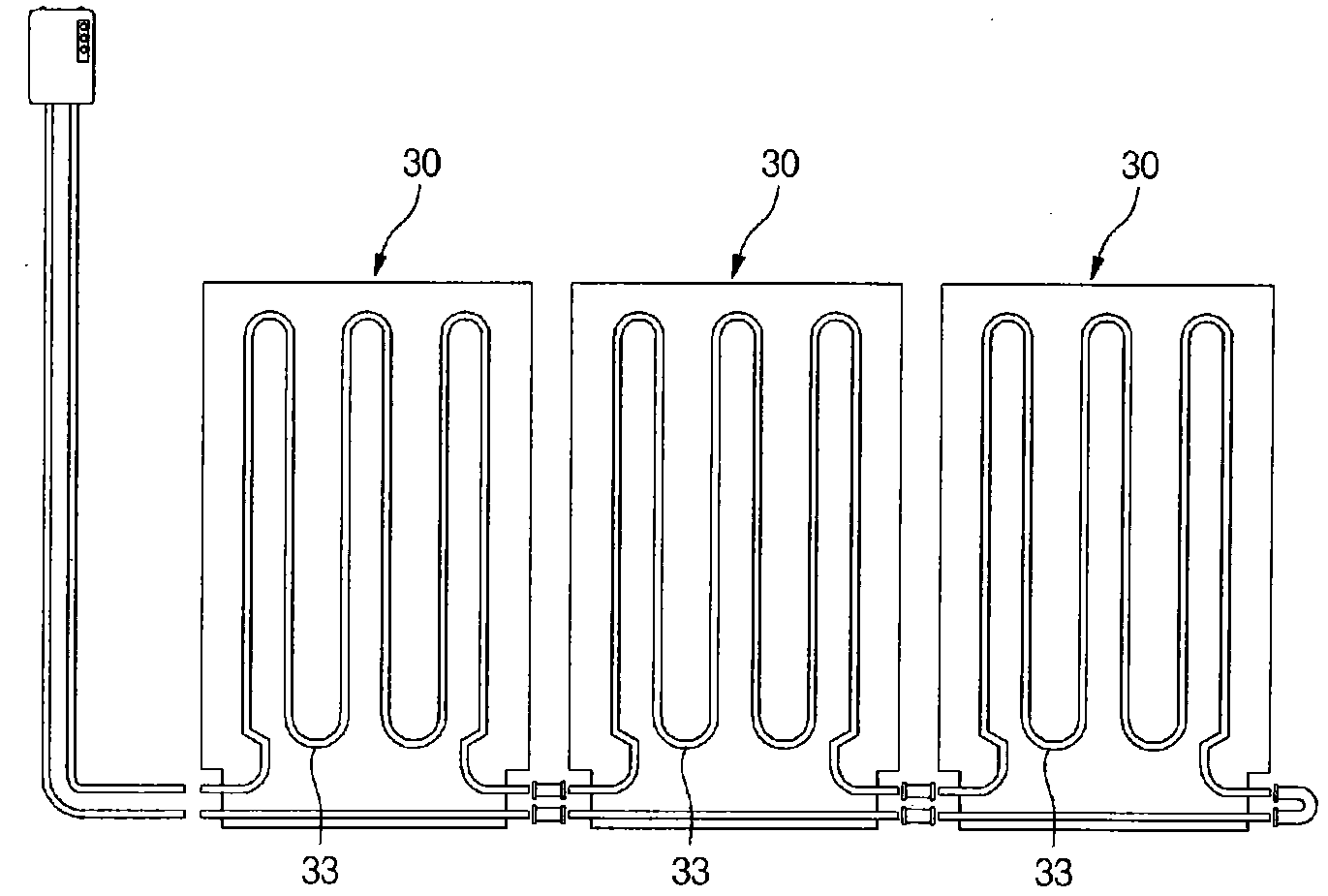

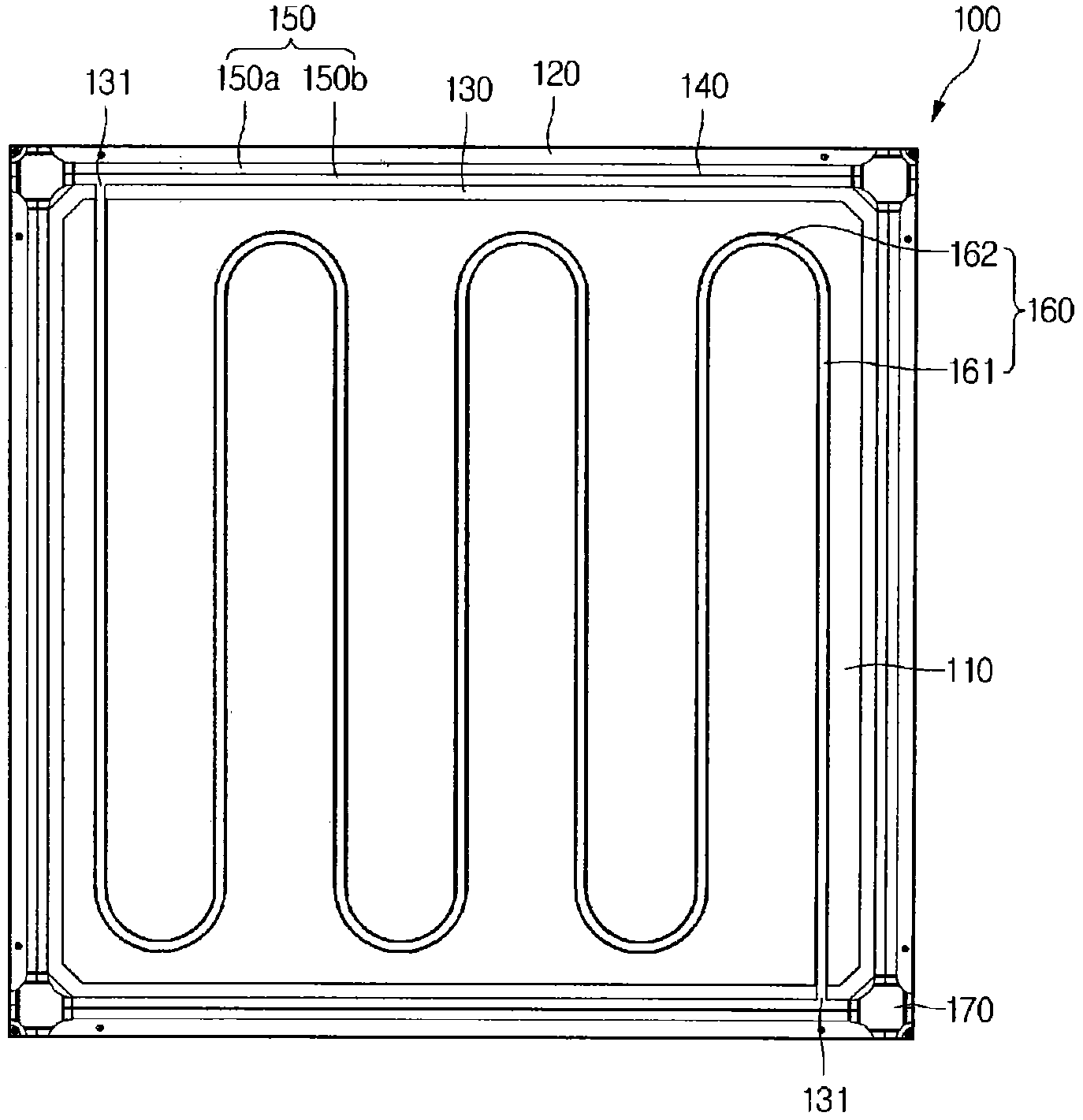

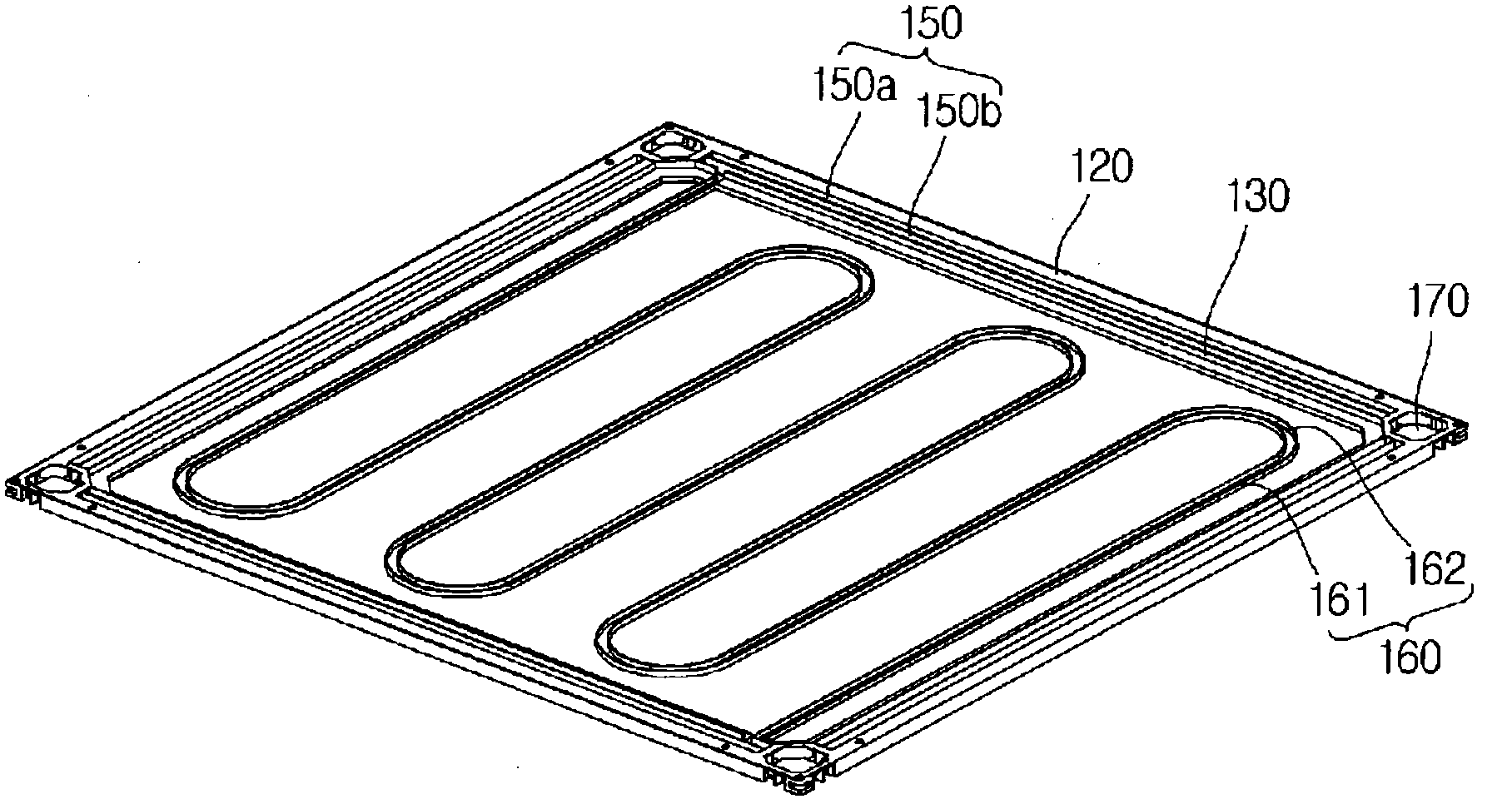

[0032] Hereinafter, a geothermal floor and a geothermal floor assembly including the geothermal floor according to an embodiment of the present invention will be described with reference to the accompanying drawings.

[0033] figure 2 is a top view of a geothermal floor 100 according to an embodiment of the present invention, image 3 is a stereogram, Figure 4 is to zoom in image 3 A schematic diagram of the corner portion 170 is shown.

[0034] When overlooking the geothermal floor 100 according to this embodiment, it includes a substantially quadrangular floor 110 , and pipe arrangement grooves 150 , 160 are arranged on the upper part of the floor 110 .

[0035] The pipe arrangement grooves 150, 160 include water pipe arrangement grooves 150 and branch pipe arrangement grooves 160, which can be formed by recessing downwards from the floor 110, or protruding upwards from the floor 110 to form a pair of protrusions for use The space between the protrusions forms a pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com