High-uniformity anti-blocking insect-preventing rotating nozzle

A technology of rotating nozzles and uniformity, which is applied in the direction of spraying devices, spraying devices, and spraying devices with movable outlets, etc. It can solve the problems that rocker nozzles cannot be installed, high pump head requirements, and uneven water distribution, etc., to achieve corrosion resistance Stable and reliable, excellent wind resistance, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

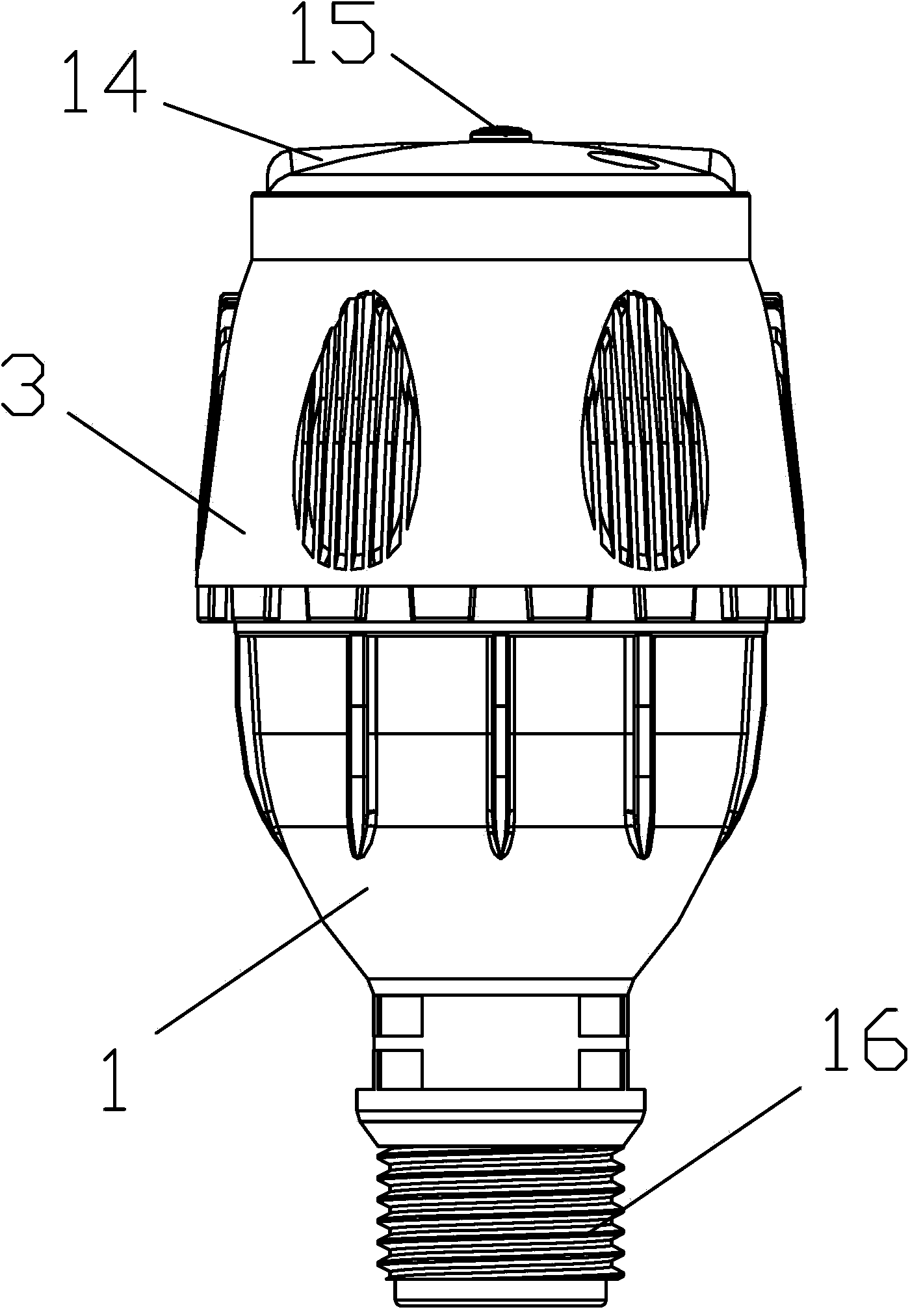

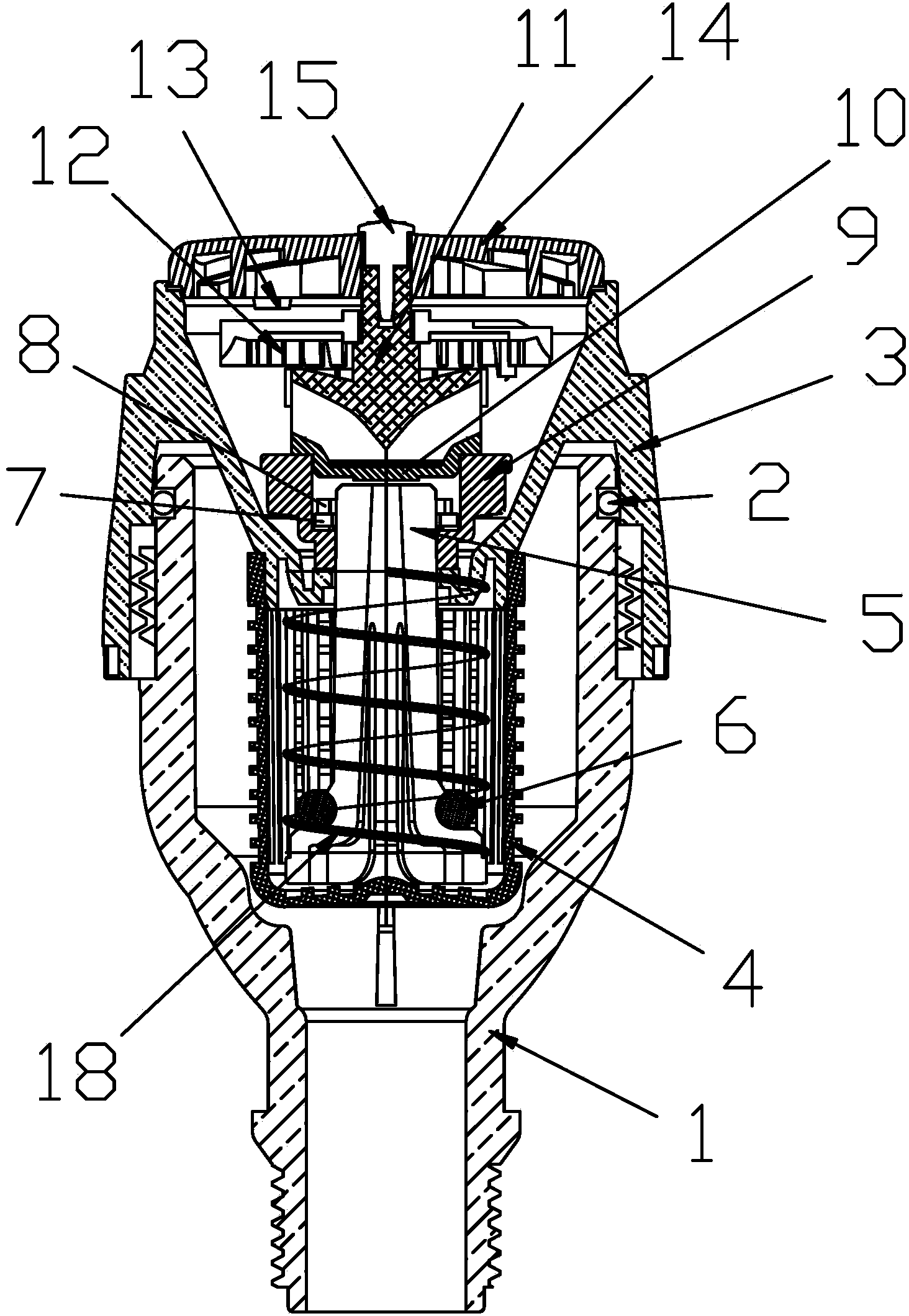

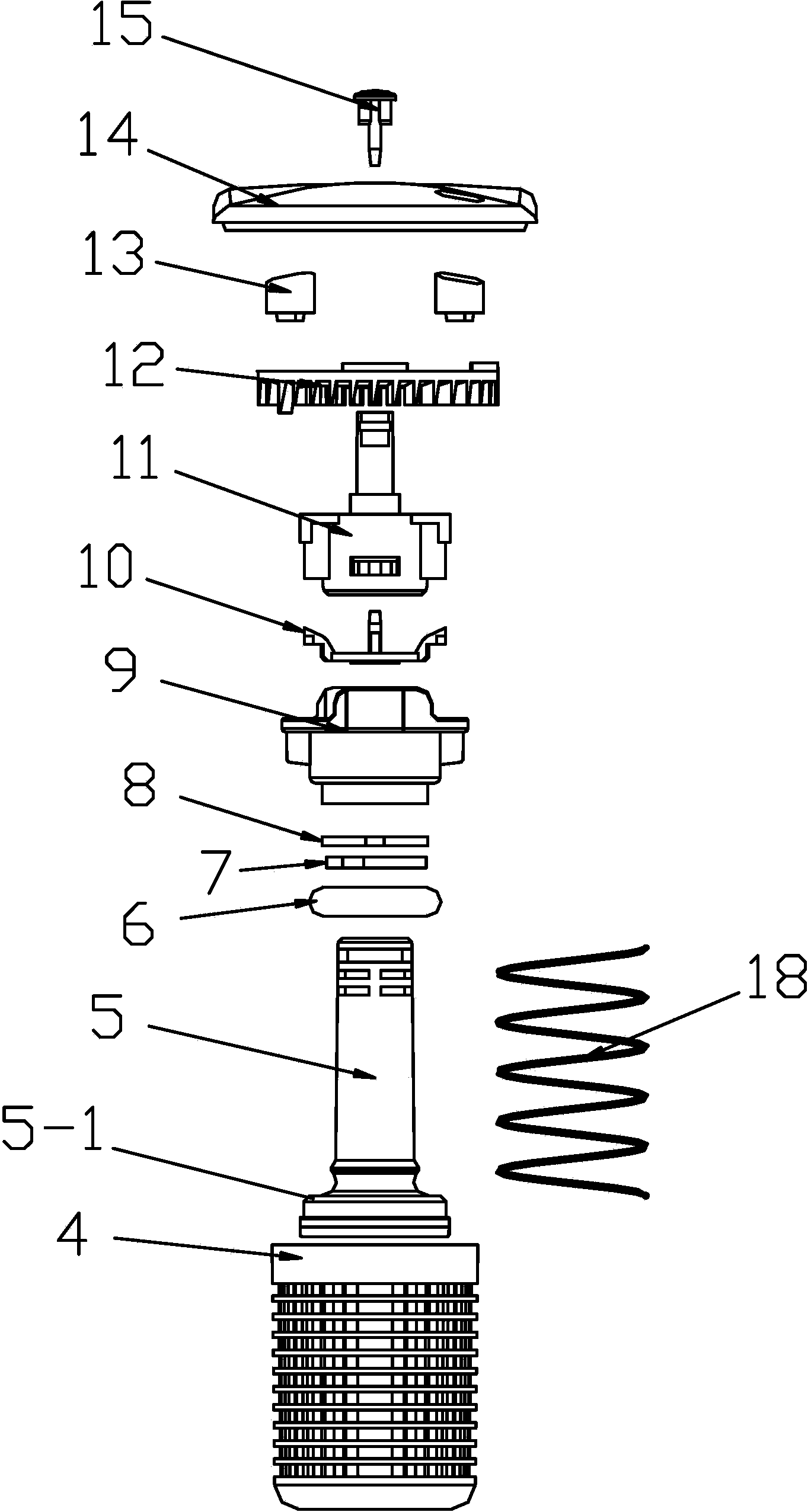

[0043] refer to figure 1 , figure 2 and image 3 As shown, a high-uniformity anti-clogging and anti-insect rotary nozzle includes an outer wire joint 16, an anti-insect casing, a nozzle working assembly 19 arranged in the anti-insect casing and a filter device 4 with a U-shaped cross section.

[0044] The anti-insect casing includes an anti-insect lower casing 1 and an upper anti-insect casing 3 which are threaded. The outer wire joint 16 is connected with the insect-proof lower shell 1, and a first sealing ring 2 is arranged between the insect-proof lower shell 1 and the insect-proof upper shell 3 to play a sealing role.

[0045] combine Figure 4 and Figure 5 As shown, the nozzle working assembly 19 includes a pin 15 , a nozzle top cover 14 , a water inlet nozzle 5 , a fixing assembly arranged in the insect-proof upper casing 3 , and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com