Modular ten-freedom-degree biped walking robot

A technology of walking robot and degree of freedom, applied in the field of robotics, can solve the problems that the harmonic reducer cannot withstand large torque and rigid impact, it is difficult to achieve high precision, and the processing cycle is long, so as to ensure the accuracy of processing, increase flexibility, Simple effects to build and tear down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] 1. At first introduce the overall mechanical structure of the present invention:

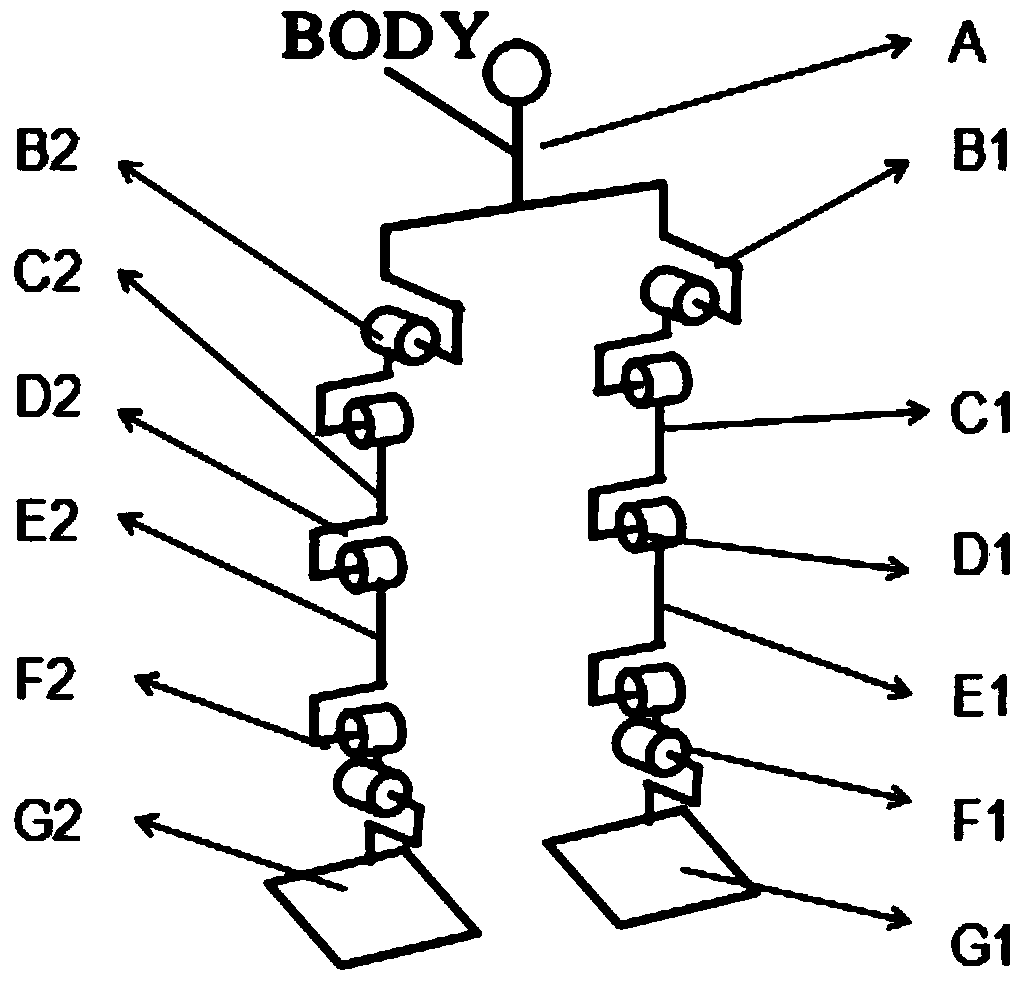

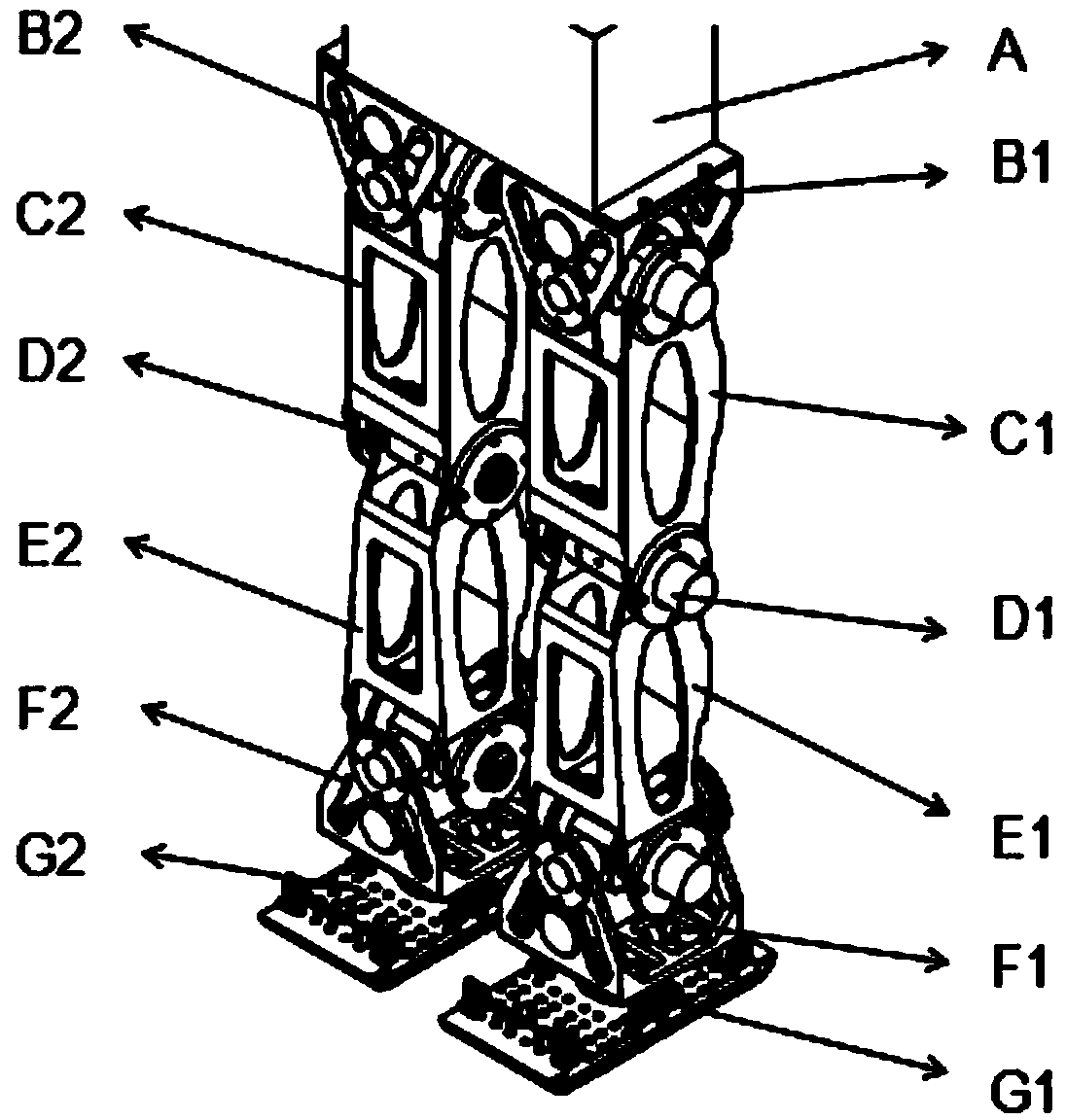

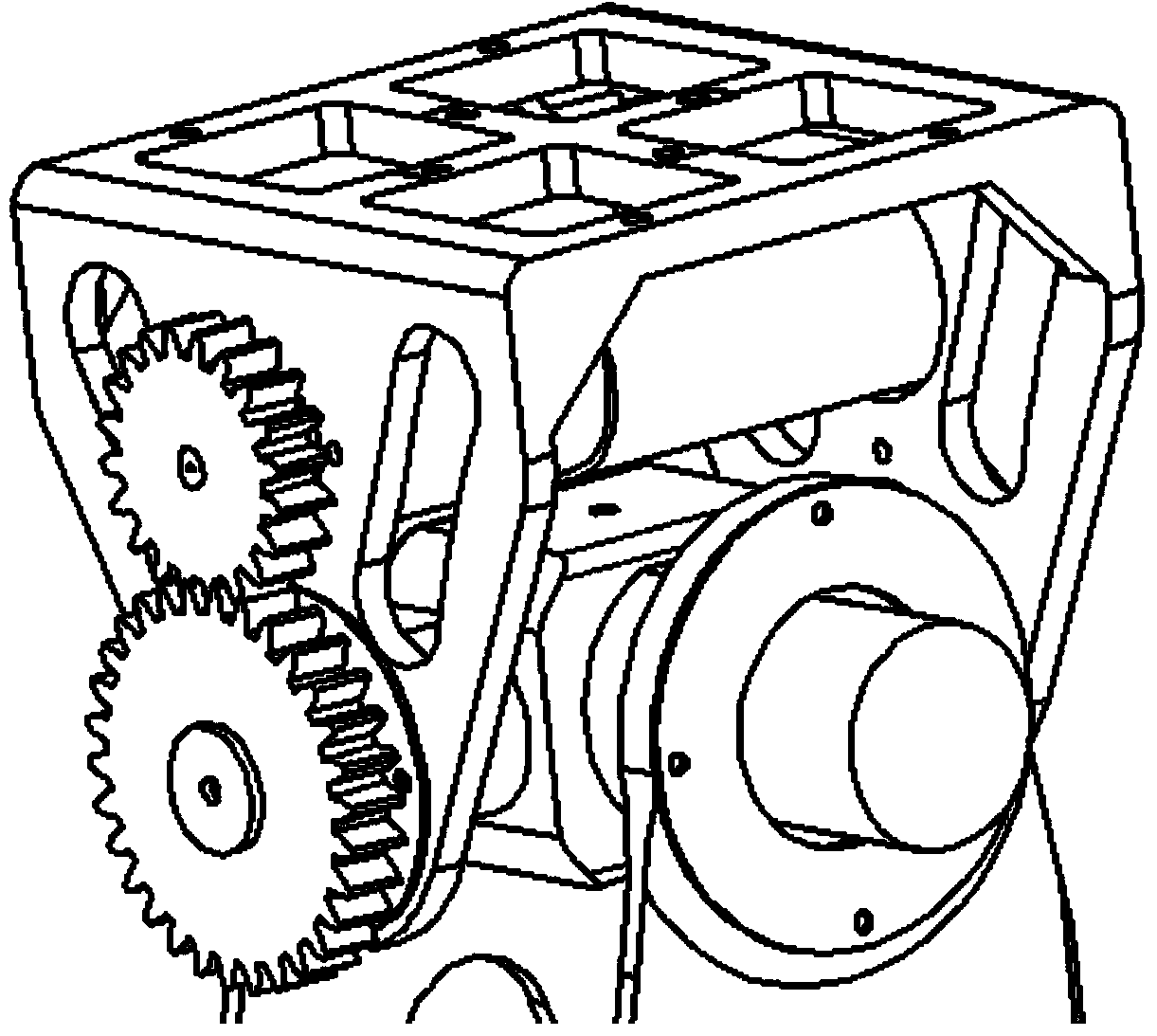

[0039] Such as figure 2 Shown, a kind of modular ten-degree-of-freedom biped walking robot involved in the present invention, the configuration of ten degrees of freedom in this robot is in figure 1 It has been shown in detail in , the hip joint and ankle joint of a single leg have two degrees of freedom, and the knee joint has one degree of freedom. The robot adopts a modular structure, including six joint modules and two foot modules. There are two types of eight modules in total. Each module is connected in series and parallel, and the sequence from one end to the other is: cross joint F1—lower leg Connecting rod E1—inline joint D1—thigh link C1—cross joint B1—cross joint B2—thigh link C2—inline joint D2—calf link E2—cross joint F2, two crosses in the middle The cross-shaped joints B1 and B2 are connected and fixed together through the upper body weight, and the cross-shaped joints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com