A kind of preparation method of iron oxide black

A technology of iron oxide black and oxidation reaction, which is applied in the field of pigment preparation, can solve the problems of poor tinting strength, long oxidation time, and many by-products of iron oxide black, and achieve strong coloring ability, avoid excessive particle size, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

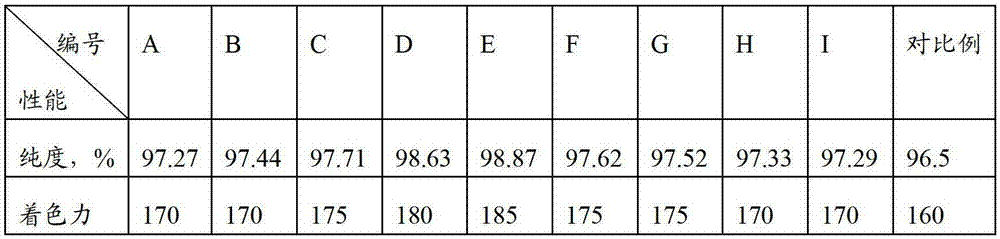

Examples

Embodiment 1

[0025] (1) Mix 1.0kg of ferrous sulfate heptahydrate and 0.6kg of sodium hydroxide evenly, and knead at 20°C to complete the reaction;

[0026] (2) adding a certain amount of water to the reacted product in the step (1) to obtain a slurry with a concentration of 90 g / L;

[0027] (3) Introduce air into the slurry in step (2) at a rate of 6 L per minute, control the pH of the reaction system to 6.5 with ammonia water at a concentration of 22 wt%, and carry out the oxidation reaction at a temperature of 20°C ;

[0028] (4) After heating the slurry after the oxidation reaction in step (3) to 60° C., add 0.5 kg of ferrous sulfate heptahydrate and 0.33 kg of sodium hydroxide to the slurry to perform an addition dehydration reaction;

[0029] (5) After the reaction is completed, filter and dry the filter cake at 60°C to obtain the finished product of iron oxide black.

Embodiment 2

[0031] (1) Mix 1.2kg of ferrous nitrate and 0.7kg of potassium hydroxide evenly, and knead at 25°C to complete the reaction;

[0032] (2) adding a certain amount of water to the reacted product in step (1) to obtain a slurry with a concentration of 120 g / L;

[0033] (3) Introduce air into the slurry in step (2) at a rate of 7 L per minute, control the pH value of the reaction system to 7.0 with ammonia water with a concentration of 15 wt%, and carry out the oxidation reaction at a temperature of 25°C ;

[0034] (4) After heating the slurry after the oxidation reaction in step (3) to 65° C., add 0.6 kg of ferrous nitrate and 0.51 kg of potassium hydroxide to the slurry to perform an addition dehydration reaction;

[0035] (5) After the reaction is completed, filter and dry the filter cake at 65°C to obtain the finished product of iron oxide black.

Embodiment 3

[0037] (1) Mix 1.4kg of ferrous chloride and 0.75kg of sodium carbonate evenly, and knead at 30°C to complete the reaction;

[0038] (2) adding a certain amount of water to the reacted product in step (1) to obtain a slurry with a concentration of 140 g / L;

[0039] (3) Introduce air into the slurry in the step (2) at a rate of 8 L per minute, control the pH value of the reaction system to 7.5 with ammonia water with a concentration of 28 wt%, and carry out the oxidation reaction at a temperature of 30°C ;

[0040] (4) After the oxidation reaction slurry in the step (3) is heated to 70°C, 0.7kg of ferrous chloride and 0.63kg of sodium carbonate are added to the slurry to perform an addition dehydration reaction;

[0041] (5) After the reaction is completed, filter and dry the filter cake at 75°C to obtain the finished product of iron oxide black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com