Aluminum alloy forged material for automobile and method for manufacturing the same

A manufacturing method and technology of forged parts, which are applied in the field of aluminum alloy forged parts for automobiles and its manufacturing, and can solve the problems of high tensile strength and elongation, low tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

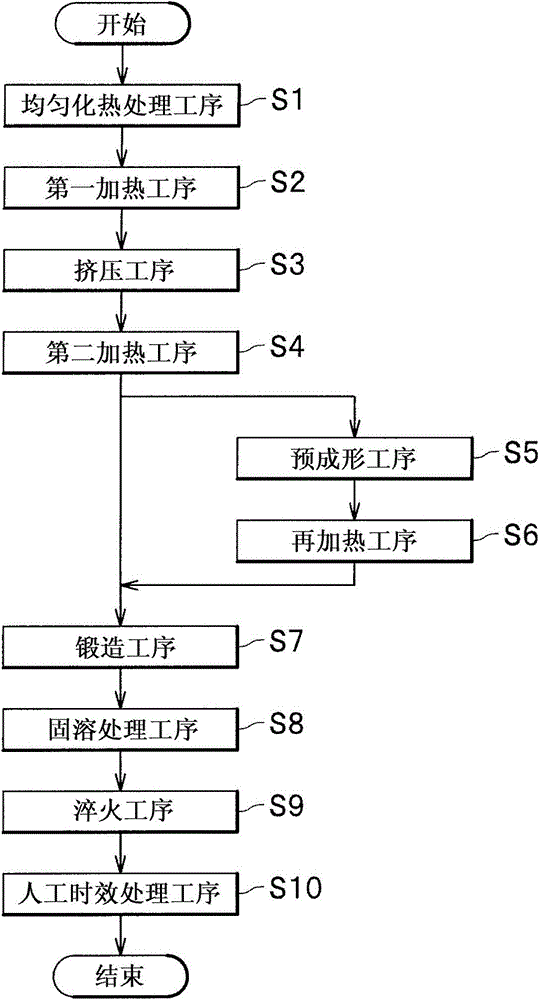

[0027] Hereinafter, the form (embodiment) for implementing the aluminum alloy forging for automobiles and the manufacturing method thereof according to the present invention will be described in detail with reference to the accompanying drawings as appropriate.

[0028] [Aluminum alloy forgings for automobiles]

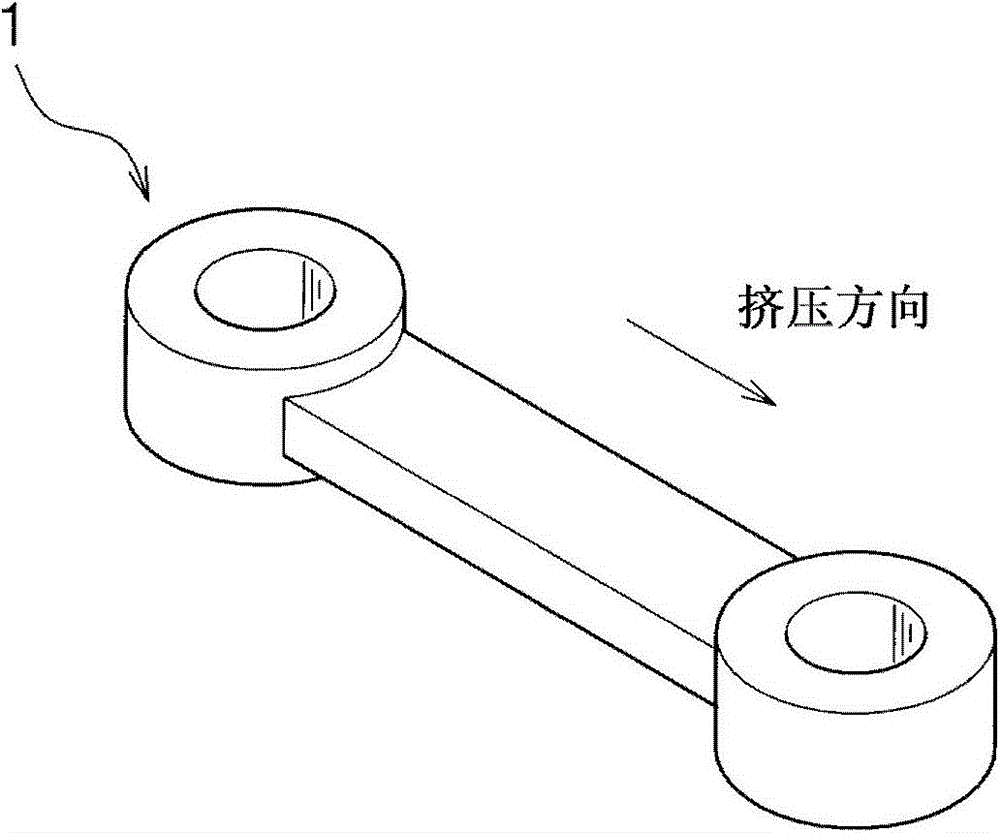

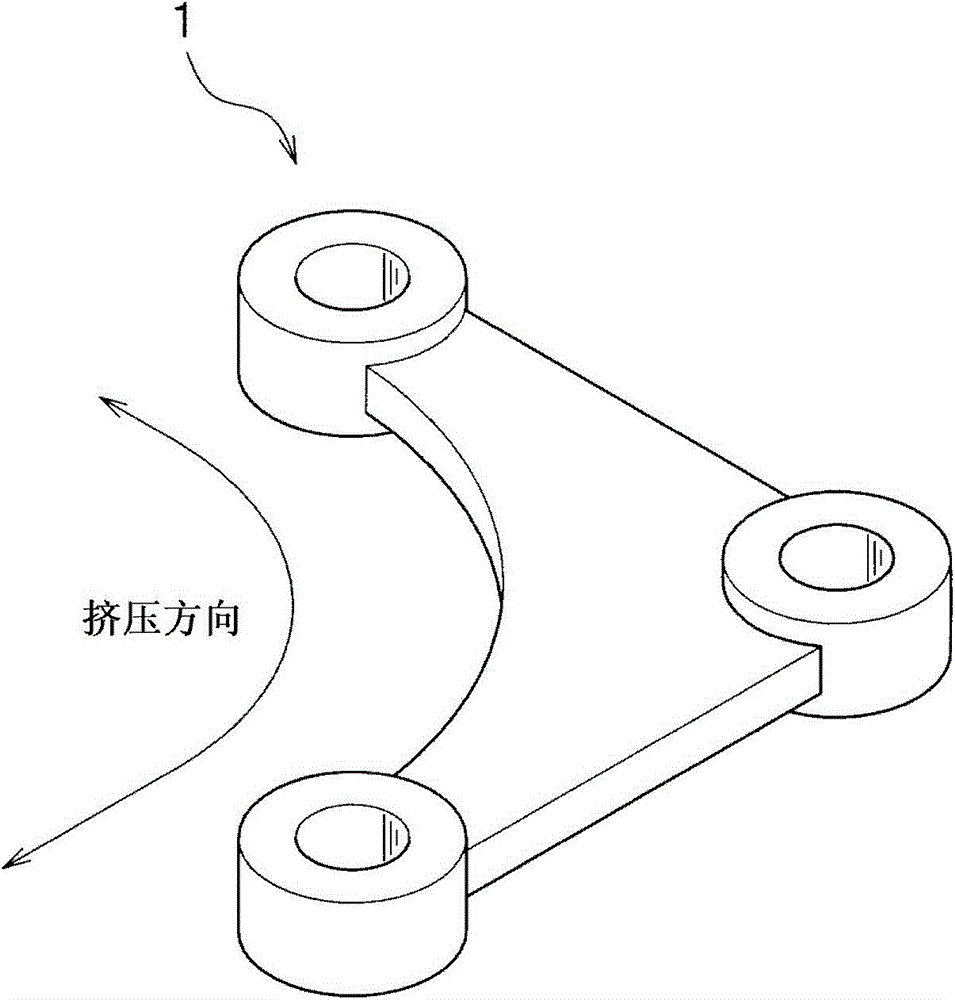

[0029] The aluminum alloy forging A for automobiles (hereinafter, simply referred to as "forging A") according to the present embodiment is produced by extrusion and forging. The application is not limited to automobiles, but can also be applied to running parts of transport aircraft such as trains, motorcycles, and airplanes, for example. Furthermore, the applicable article is not limited to the running member, and can also be applied to a structural member (structural product) other than the running member.

[0030] The alloy composition of the forging A according to the present embodiment contains Si: 0.7 to 1.5 mass %, Fe: 0.5 mass % or less, Cu: 0.1 to 0.6 mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com