Blended superfine dust-free cloth and preparation method thereof

A clean cloth, polyester and nylon ultra-fine fiber technology, used in textiles and papermaking, dry cleaning fiber products, weft knitting and other directions, can solve the problems of increased product cost, rough surface, high price, etc., to improve cleaning cleanliness, The effect of simplifying the washing process and preventing reverse contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

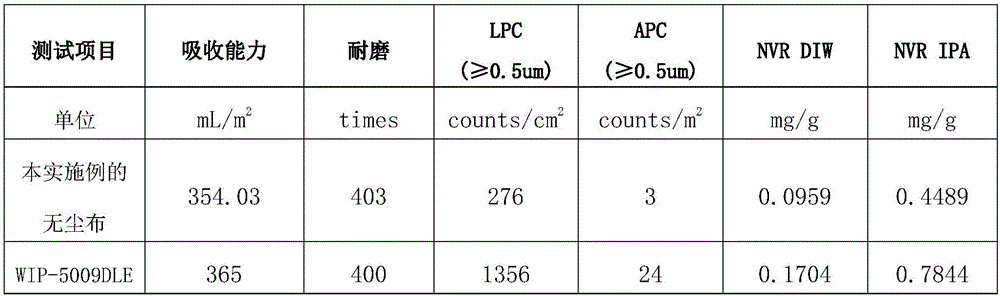

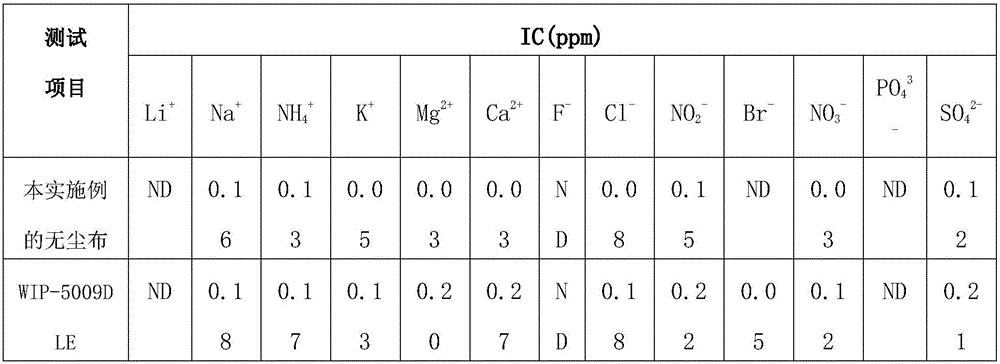

Examples

Embodiment 1

[0033] It is the preparation example of dust-free cloth.

[0034] A blended ultrafine dust-free cloth is prepared according to the following steps:

[0035] 1) The polyester yarn 50D / 72F with a mass ratio of 1:2 and the polyester nylon superfine fiber yarn 75D / 35F are mixed and woven with a 40-needle circular knitting machine to make a gray cloth; the grammage of the prepared gray cloth is 105 ±12g / m 2 , width 2.24±0.02m, thickness 0.44±0.04mm;

[0036] 2) Add RO water (about 2400L) into the dye vat, and put the gray cloth prepared in step 1) into the dye vat according to the bath ratio of 1:6;

[0037] 3) Add penetrant JFC 1.2g / L, sodium hydroxide 8g / L, EDTA-4Na 1.2g / L, and degreasing agent LZC301A 3g / L into the dye vat; raise the temperature of the solution in the dye vat to 110°C and keep it warm for 35 minutes, a total of 40 minutes;

[0038] 4) Clean the gray cloth in the dye vat by washing while discharging, cool down to 50°C, keep warm for 3 minutes, and take a tota...

Embodiment 2

[0048] It is the preparation example of dust-free cloth.

[0049] A blended ultrafine dust-free cloth is prepared according to the following steps:

[0050] 1) The polyester yarn 50D / 72F with a mass ratio of 1:2 and the polyester nylon superfine fiber yarn 75D / 35F are mixed and woven with a 40-needle circular knitting machine to make a gray cloth; the grammage of the prepared gray cloth is 105 ±12g / m 2 , width 2.24±0.02m, thickness 0.44±0.04mm;

[0051] 2) Add RO water (about 2400L) into the dye vat, and put the gray cloth prepared in step 1) into the dye vat according to the liquor ratio of 1:7;

[0052] 3) Add penetrating agent JFC 1.5g / L, sodium hydroxide 10g / L, EDTA-4Na 1.5g / L, and degreaser (the degreaser in this example is LZC301A produced by Lianzhuang Technology) 4g / L in the dye vat L; raise the temperature of the solution in the dye vat to 110°C, keep it warm for 35 minutes, and take a total of 40 minutes;

[0053] 4) Clean the gray cloth in the dye vat by washing...

Embodiment 3

[0063] It is the preparation example of dust-free cloth.

[0064] A blended ultrafine dust-free cloth is prepared according to the following steps:

[0065] 1) The polyester yarn 50D / 72F with a mass ratio of 1:2 and the polyester nylon superfine fiber yarn 75D / 35F are mixed and woven with a 40-needle circular knitting machine to make a gray cloth; the grammage of the prepared gray cloth is 105 ±12g / m 2 , width 2.24±0.02m, thickness 0.44±0.04mm;

[0066] 2) Add RO water (about 2400L) into the dye vat, and put the gray cloth prepared in step 1) into the dye vat according to the bath ratio of 1:5;

[0067] 3) Add penetrating agent JFC 1g / L, sodium hydroxide 6g / L, EDTA-4Na 1g / L, and degreaser (the degreaser of this embodiment is LZC301A produced by Lianzhuang Technology) 2g / L in the dye vat; Raise the temperature of the solution in the dye vat to 105°C and keep it warm for 35 minutes, a total of 40 minutes;

[0068] 4) Clean the gray cloth in the dye vat by washing while disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com