Background wall soft package structure with batten

A background wall and soft package technology, applied in building structure, covering/lining, construction, etc., can solve the problems of inability to disassemble and replace, and achieve the effect of convenient disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

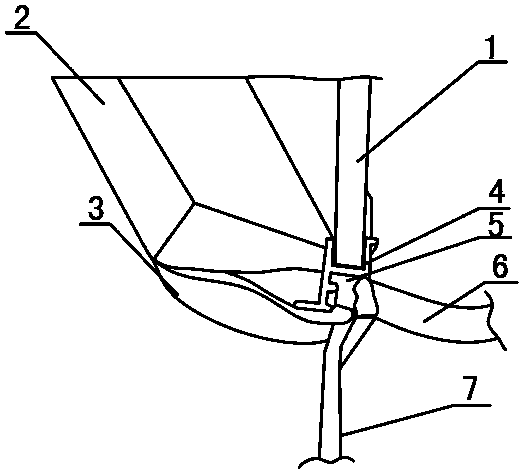

[0023] Such as Figure 1-3 As shown, the background wall soft package structure with clamping strips described in the embodiment of the present invention includes a backboard 1, a sponge layer 2, a fabric layer 3 and an H-shaped aluminum strip, and the H-shaped aluminum strip is composed of the H-shaped aluminum strip The frame 4 is composed of an H-shaped aluminum strip outer frame 5, wherein the H-shaped aluminum strip inner frame 4 is fixed and clamped to the back panel 1, and the H-shaped aluminum strip outer frame 5 is provided with a fastening rubber strip 7 for clamping the fabric layer 3 , filling the sponge layer 2 between the fabric layer 3 and the H-shaped aluminum strip;

[0024] Correspondingly, the fastening rubber strip 7 is used to fix the fabric, and since no nails are used, the outer fabric can be easily disassembled at any time, which is convenient for disassembly and replacement;

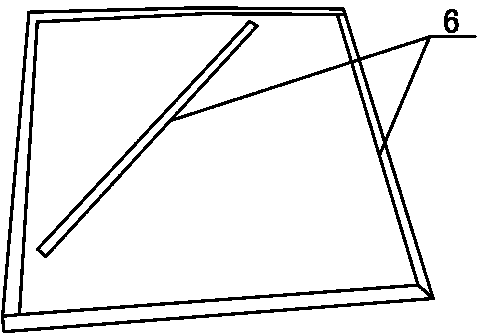

[0025] Correspondingly, Velcro 6 is provided on the outer edge of the H-sha...

Embodiment 2

[0027] Such as Figure 1-3 As shown, the background wall soft package structure with clamping strips described in the embodiment of the present invention includes a backboard 1, a sponge layer 2, a fabric layer 3 and an H-shaped aluminum strip, and the H-shaped aluminum strip is composed of the H-shaped aluminum strip The frame 4 is composed of an H-shaped aluminum strip outer frame 5, wherein the H-shaped aluminum strip inner frame 4 is fixed and clamped to the back panel 1, and the H-shaped aluminum strip outer frame 5 is provided with a fastening rubber strip 7 for clamping the fabric layer 3 , filling the sponge layer 2 between the fabric layer 3 and the H-shaped aluminum strip;

[0028] Correspondingly, the fastening rubber strip 7 is used to fix the fabric, and since no nails are used, the outer fabric can be easily disassembled at any time, which is convenient for disassembly and replacement.

Embodiment 3

[0030] Such as Figure 1-3 As shown, the background wall soft package structure with clamping strips described in the embodiment of the present invention includes a backboard 1, a sponge layer 2, a fabric layer 3 and an H-shaped aluminum strip, and the H-shaped aluminum strip is composed of the H-shaped aluminum strip The frame 4 is composed of an H-shaped aluminum strip outer frame 5, wherein the H-shaped aluminum strip inner frame 4 is fixed and clamped to the back panel 1, and the H-shaped aluminum strip outer frame 5 is provided with a fastening rubber strip 7 for clamping the fabric layer 3 , filling the sponge layer 2 between the fabric layer 3 and the H-shaped aluminum strip;

[0031] The outer edge of the H-shaped aluminum strip and the back of the backboard 1 are respectively provided with Velcro 6, which can be disassembled, replaced, and cleaned at will. The Velcro 6 is pasted with glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com