Ultra torsion resistance multi-shoulder full-enclosed taper pipe thread connecting device

A tapered pipe thread and connecting device technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problem that the sealing performance depends on the axial load and axial contact stress, the elastic deformation contact stress of the sealing mating surface cannot be guaranteed Sealing performance and other issues to achieve the effect of ensuring safety and stability, strong sealing contact stress, and elastic deformation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

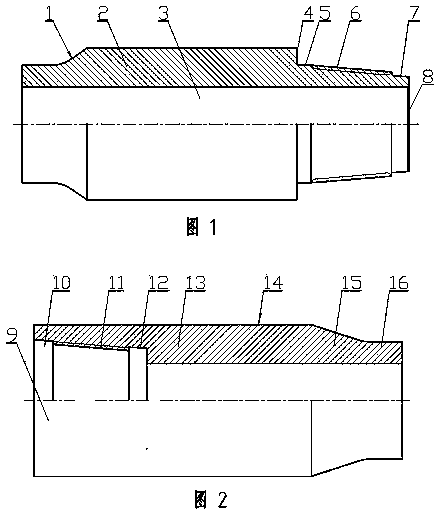

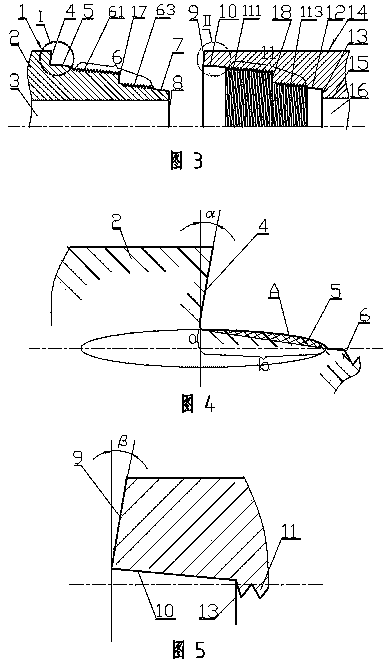

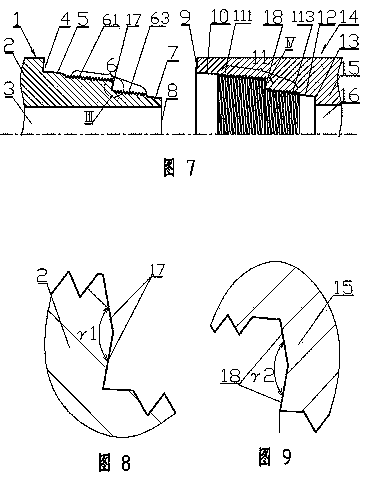

[0030] The double-shouldered drill pipe joints are composed of an externally threaded joint 1 and an internally threaded joint 14 that are threaded and engaged with each other. One end of the externally threaded joint 1 is fixedly connected to one end of a drill pipe, the other end of the externally threaded joint 1 is connected to the internally threaded joint 14 through the connecting thread, and the other end of the internally threaded joint 14 is fixed to another drill pipe. Connection, in order to complete the extension connection of each section of drill pipe.

[0031] like figure 1 As shown, the externally threaded joint 1 of the traditional double-shouldered drill pipe joint includes an externally threaded joint body 2 made of forgings. The lumen 3 communicates with the bore of the drill pipe. One end of the externally threaded joint body 2 is fixedly connected to the drill pipe, and the other end is a threaded connection. The threaded connection end portion on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com