Method for processing large-scale underground goaf

A goaf, large-scale technology, applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve problems such as labor and time-consuming, hidden safety hazards left by shovel loading in goaf, and impact on blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

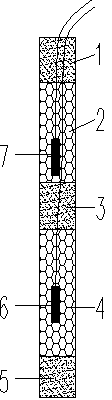

Image

Examples

Embodiment Construction

[0032] Embodiment: take 1740-10-empty 7 as an example.

[0033] 1. Understand the shape of 1740-10-Kong 7 through the 3D laser scanning report.

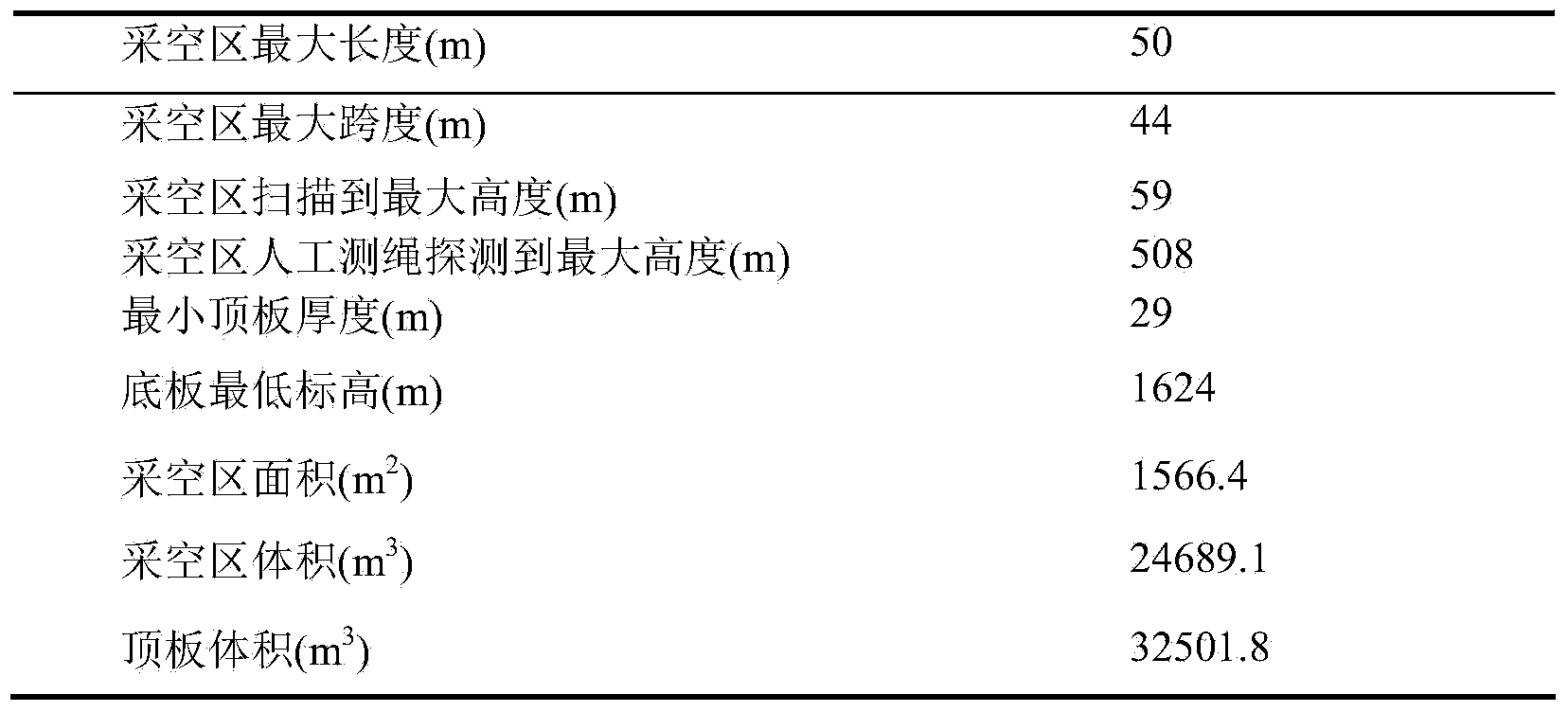

[0034] From the 3D modeling composite diagram, it can be seen that the goaf is a gourd-shaped multi-layer goaf, and the parameters of the goaf are shown in Table 1:

[0035] Table 1 Goaf parameters

[0036]

[0037] 2. Determine the reasonable security layer thickness and the timing of empty area treatment according to the ore rock structure.

[0038] According to the "Summary Report on the Research on the Stability of Open-pit Mining in the Upper Goaf of Yuanjia Village Iron Mine of Taiyuan Iron and Steel Co., Ltd. and the Research on Goaf Treatment Technology" provided by Changsha Mining Research Institute, hematite is mainly hematite, followed by magnetite. The formula for calculating the thickness of the security layer :

[0039] h=0.683b-0.944

[0040] In the formula, h is the thickness of the security layer, m; b is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com