Rotary compressor

A technology of rotary compressors and compression mechanisms, applied in the field of rotary compressors, can solve problems such as difficulties, and achieve the effects of reduced axial spacing and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

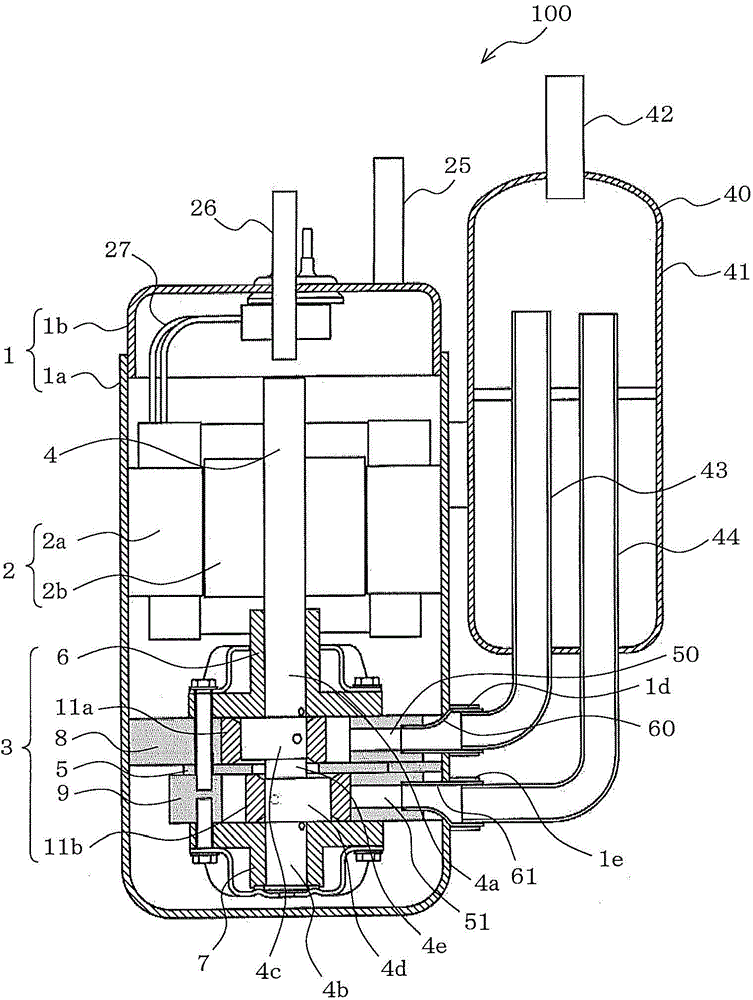

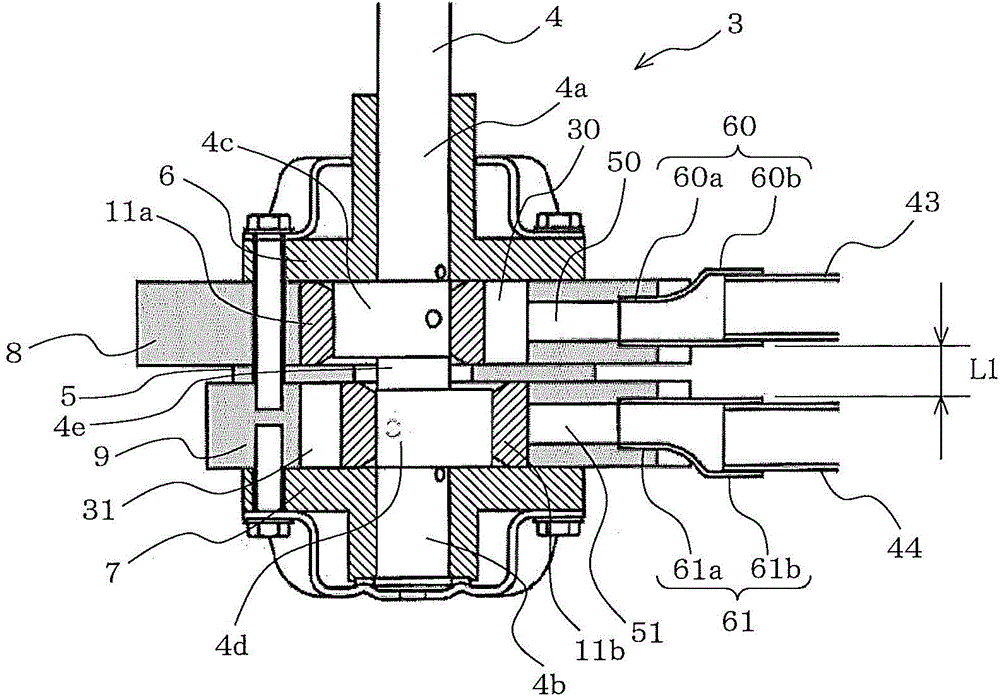

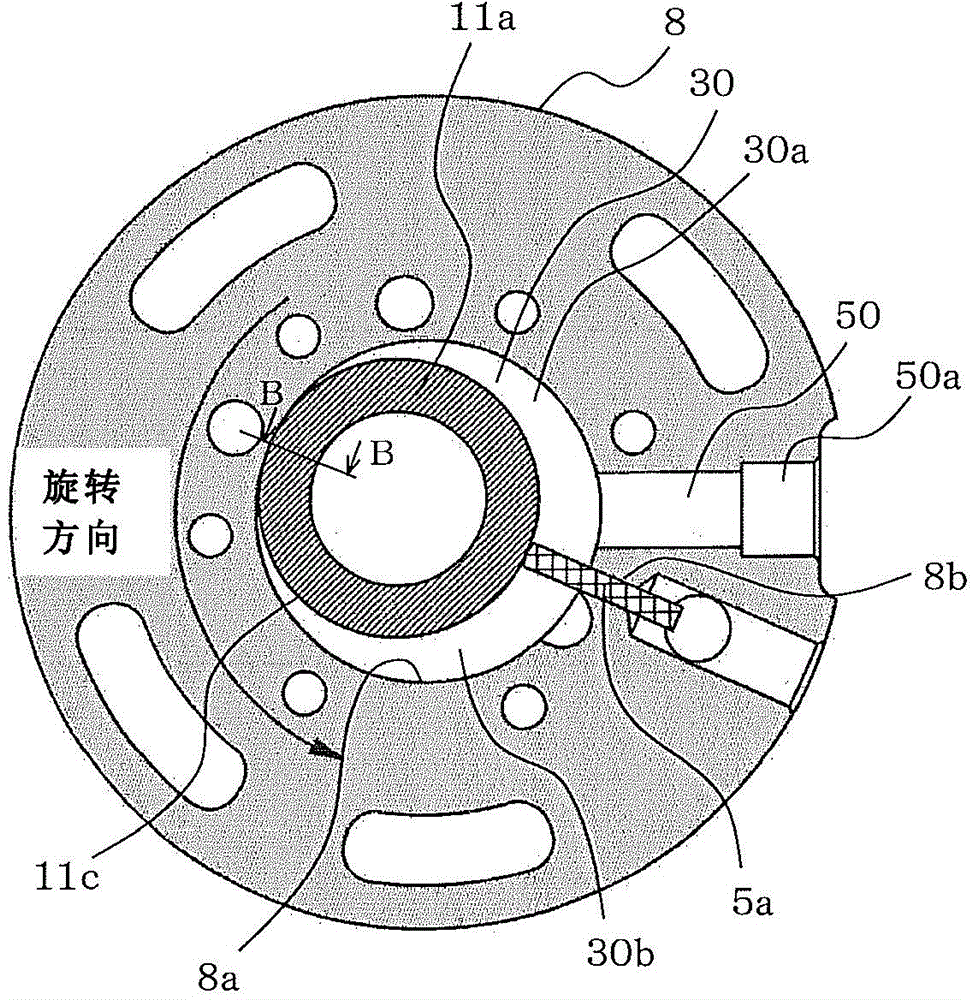

[0034] figure 1 It is a vertical sectional view of the rotary compressor 100 according to Embodiment 1 of the present invention. figure 2 yes figure 1 An enlarged view of the compression mechanism 3. image 3 yes figure 1 A cross-sectional view of the first cylinder 8. The drawings show a two-cylinder rotary compressor with two cylinders, but the rotary compressor of the present invention is not limited to a two-cylinder structure, and may also adopt a multi-cylinder structure.

[0035] The rotary compressor 100 includes a motor 2 and a compression mechanism 3 driven by the motor 2 via a crankshaft 4 in a sealed container 1 .

[0036] The airtight container 1 has a structure in which the upper container 1b and the main body 1a are integrated by welding. Refrigerator oil (not shown) for lubricating the sliding portion of the compression mechanism 3 is stored in the bottom of the airtight container 1 . In addition, on the upper portion of the airtight container 1 , a c...

Embodiment approach 2

[0082] In the second embodiment, the pressure-tightness of the connecting pipes 60 , 61 to the suction ports 50 , 51 is improved.

[0083] The connection pipes 60 , 61 of Embodiment 2 differ from Embodiment 1 in cross-sectional shape on the suction port side connection portions 60 a , 61 a side, and are the same as Embodiment 1 except for that. Hereinafter, the differences between Embodiment 2 and Embodiment 1 will be mainly described. In addition, the structure for improving pressure-tightness is the same in the connection pipes 60 and 61, and below, the connection pipe 60 is demonstrated as a representative.

[0084] Figure 11 is a sectional view of key parts of a rotary compressor according to Embodiment 2 of the present invention, and shows that Figure 9 (a) is a schematic diagram showing the direction of internal stress of the connecting pipe 60 when the suction port side connecting portion 61a of the connecting pipe 60 is press-fitted into the suction port 50 having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com