Buffering oil cylinder

A buffer oil cylinder and buffer sleeve technology, applied in the field of hydraulic oil cylinders, can solve the problems of large pressure shock, easy jamming, jitter and crawling of the buffer oil cylinder, so as to reduce the pressure shock, prevent the sudden sharp increase of oil pressure, and prevent jitter. and crawling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

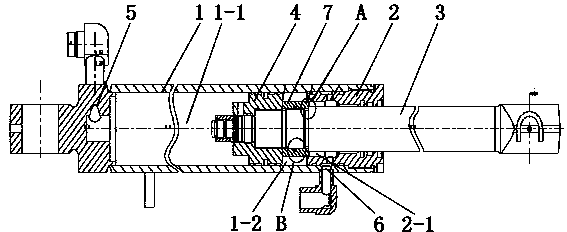

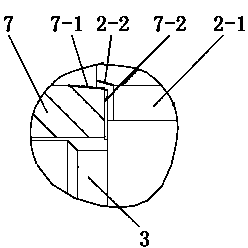

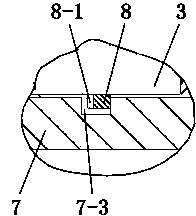

[0023] figure 1 and figure 2 The buffer oil cylinder shown mainly includes a cylinder body, a piston 4, a piston rod 3 and a buffer sleeve 7. The cylinder body is composed of a cylinder barrel 1 and a cylinder head 2. One end of the piston rod 3 extends into the cylinder through the through hole in the middle of the cylinder head 2. Inside the barrel 1, the other end is exposed outside the cylinder body. The piston rod 3 and the cylinder head 2 together cover the barrel mouth of the cylinder barrel 1. The part of the piston rod 3 that can extend into the cylinder body has a piston installation section and a buffer sleeve installation that are connected in sequence. Piston 4 is set in the cylinder barrel 1 and is set on the piston installation section at the inner end of the piston rod 3. The piston 4 separates the inner chamber of the cylinder body to form a rodless chamber 1-1 and a rodless chamber 1-1. The rod chamber 1-2, the cylinder 1 is provided with the oil return por...

Embodiment 2

[0026] Such as Figure 7 The buffer ring of the buffer oil cylinder shown is a closed ring, and other features are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com