Mass and mass center measuring device for guided missile in irregular shape

A measuring device and shape technology, which is applied in the field of measurement and control, can solve problems such as the inability to meet the measurement requirements of the center of mass of missiles with irregular shapes, and achieve the effects of convenient and fast measurement, high reliability, and strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

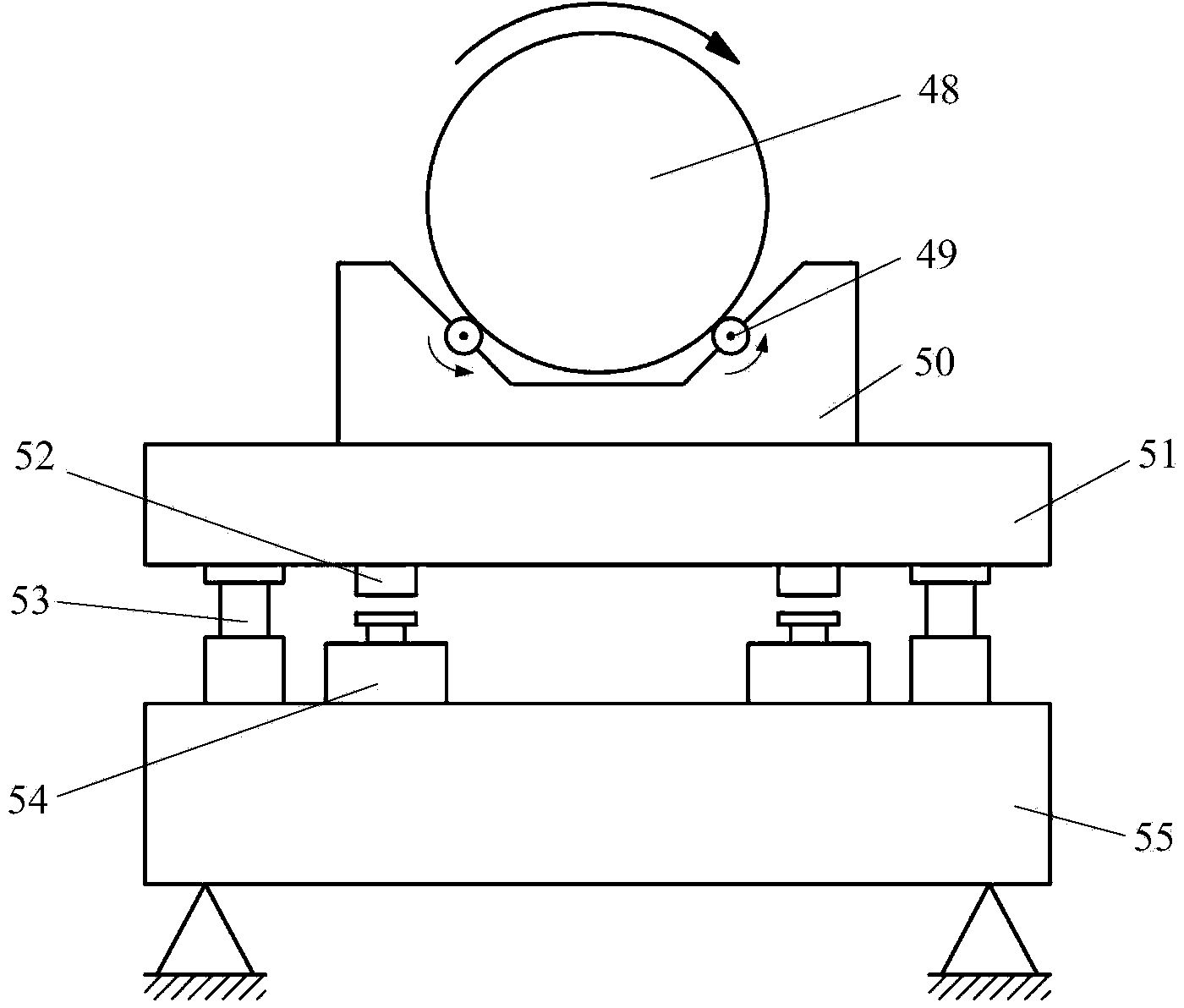

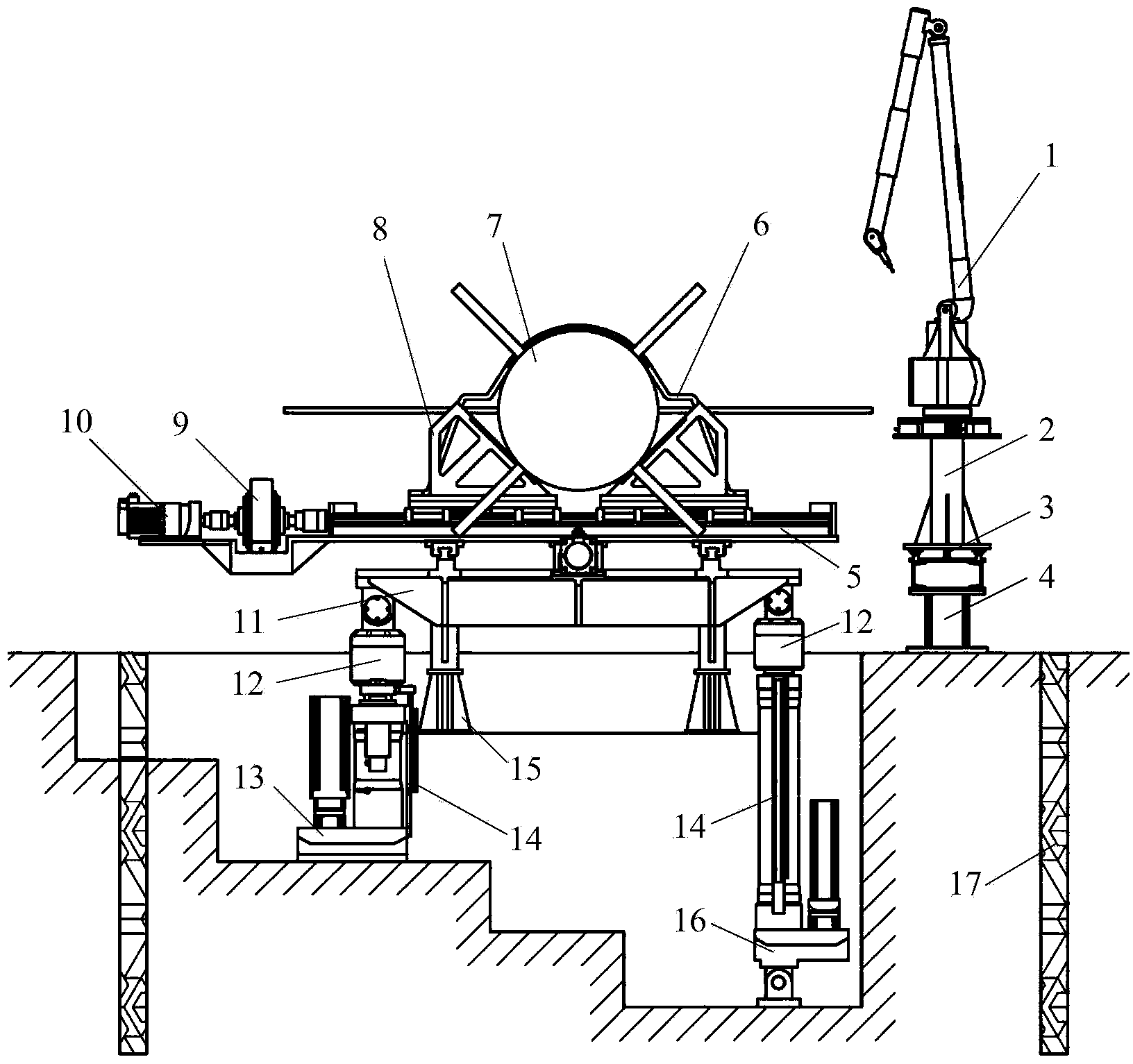

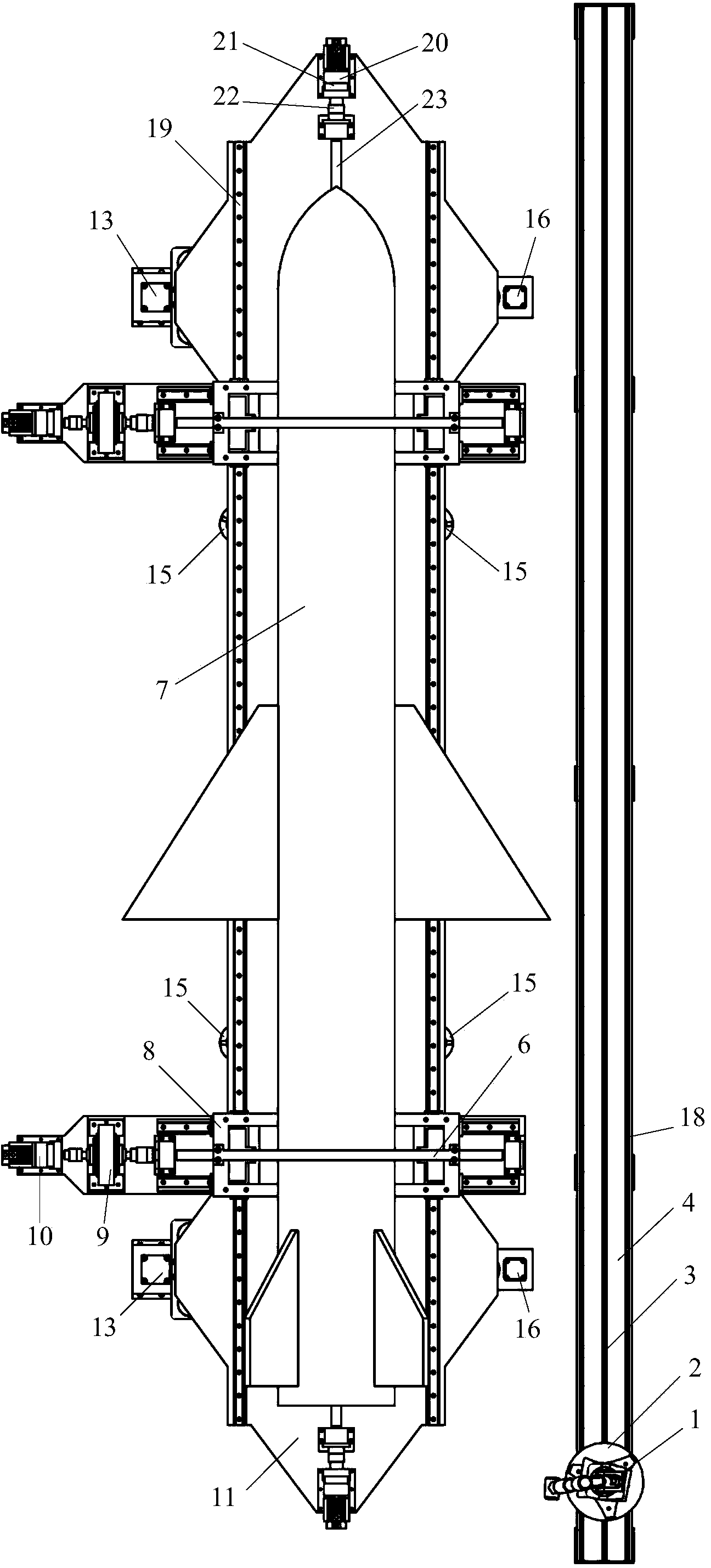

[0027] figure 2 , image 3 It is a schematic view of the front structure and a schematic view of the top view structure of the present invention. It includes a lifting support unit composed of a load-bearing platform 11, a flange seat type electric push rod 13, an articulated seat type electric push rod 16, and a fixed support base 15. The sensor unit composed of the load cell 12 and the grating ruler 14, the clamp unit composed of the clamp body 8, the clamp ring 6, the clamp platform 5, the clamp horizontal drive motor 10, and the clamp longitudinal drive motor 20, with the joint measuring arm 1. A measuring arm system composed of an arm mounting base 2 and a measuring arm base 4. The load-bearing platform 11 has a symmetrical structure, and there are 8 symmetrically arranged fulcrums underneath; among them, a pair of articulated seat type electric push rods 16 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com