Comprehensive servo motor and harmonic speed reducer testing platform

A harmonic reducer and servo motor technology, which is applied in machine gear/transmission mechanism testing, engine testing, machine/structural component testing, etc., can solve problems such as laborious and laborious, inaccurate detection data, and reduced coaxiality , to achieve the effects of simple and reasonable structure setting, high accuracy of detection data, and convenient assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below in conjunction with the accompanying drawings.

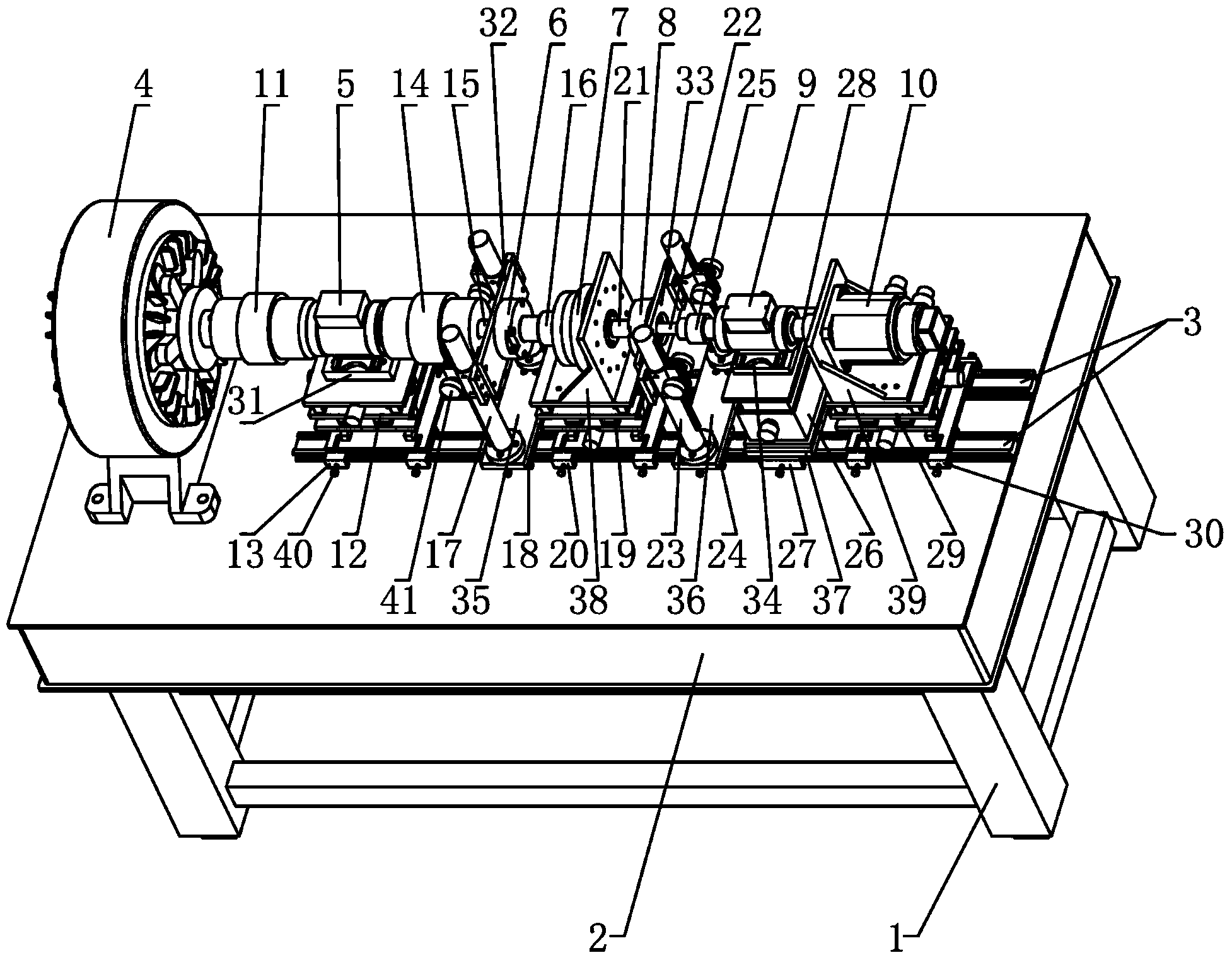

[0028] Such as figure 1 The comprehensive test platform for servo motors and harmonic reducers shown includes a frame 1, a vibration isolation platform 2 installed on the frame 1, and a linear guide rail 3 and a magnetic powder brake 4 installed on the vibration isolation platform 2. The linear guide rail 3 is equipped with a large-range torque speed sensor 5 , a first angle encoder 6 , a harmonic reducer 7 , a second angle encoder 8 , a small-range torque speed sensor 9 , and a servo motor 10 .

[0029] The output shaft of the magnetic powder brake 4 is connected with the large-range torque speed sensor 5 through the first shaft coupling 11, and the large-range torque speed sensor 5 is fixedly installed on the first three-dimensional displacement platform 12, and the first three-dimensional The bottom of the translation stage 12 is fixed with a first slider 13 which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com